CX-JV77

3

TABLE OF CONTENTS

1. SERVICING NOTES ................................................ 4

2. GENERAL

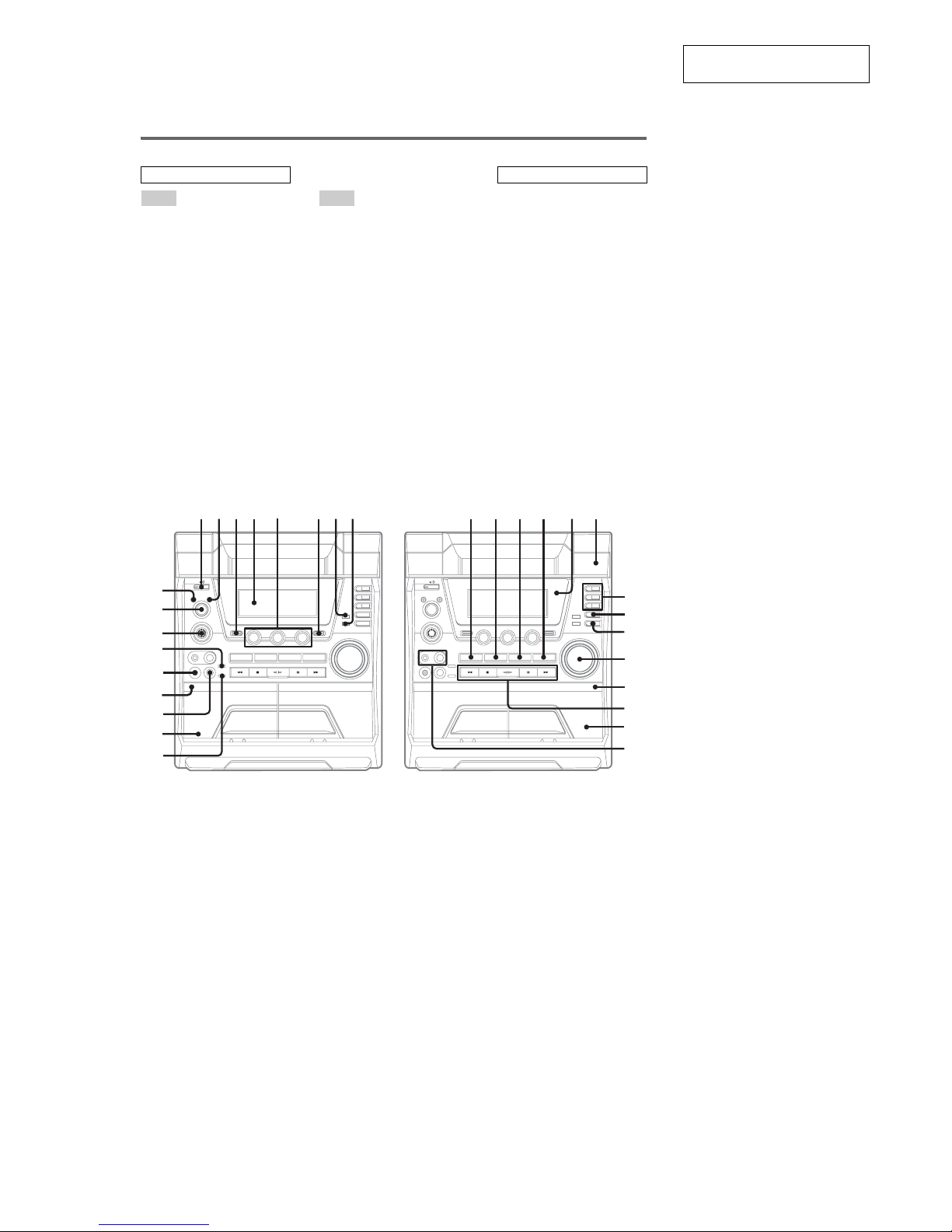

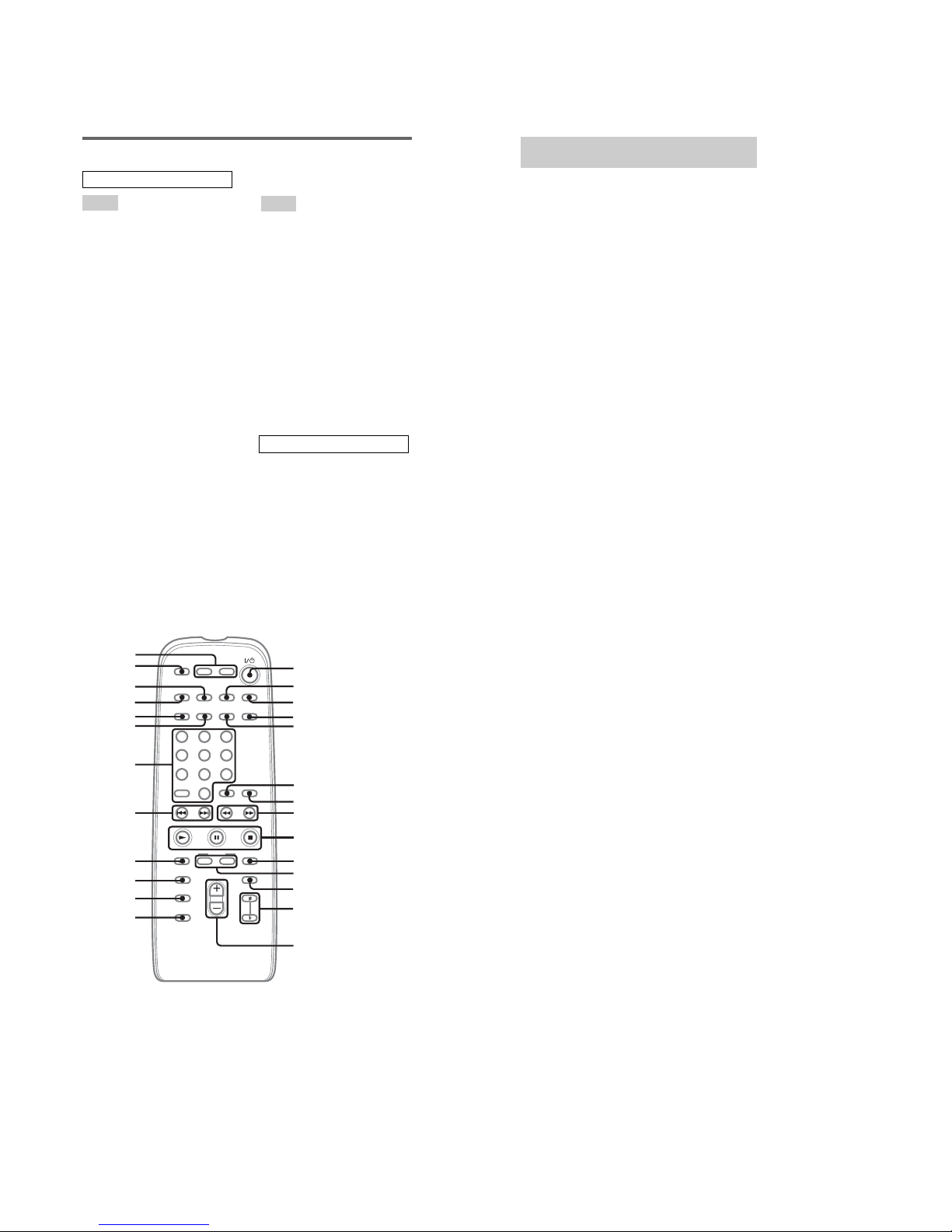

Location of Controls........................................................ 7

3. DISASSEMBLY

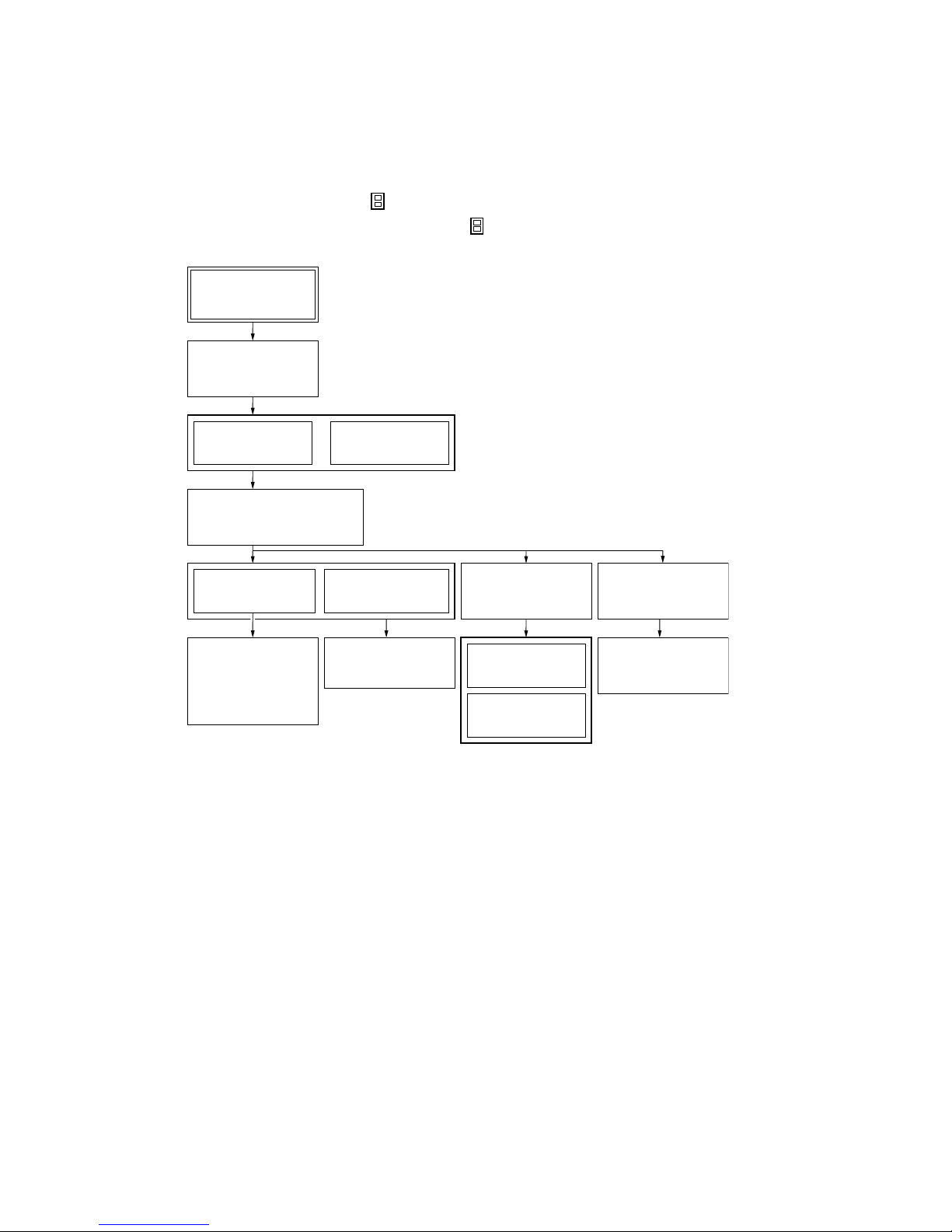

3-1. Disassembly Flow ........................................................... 9

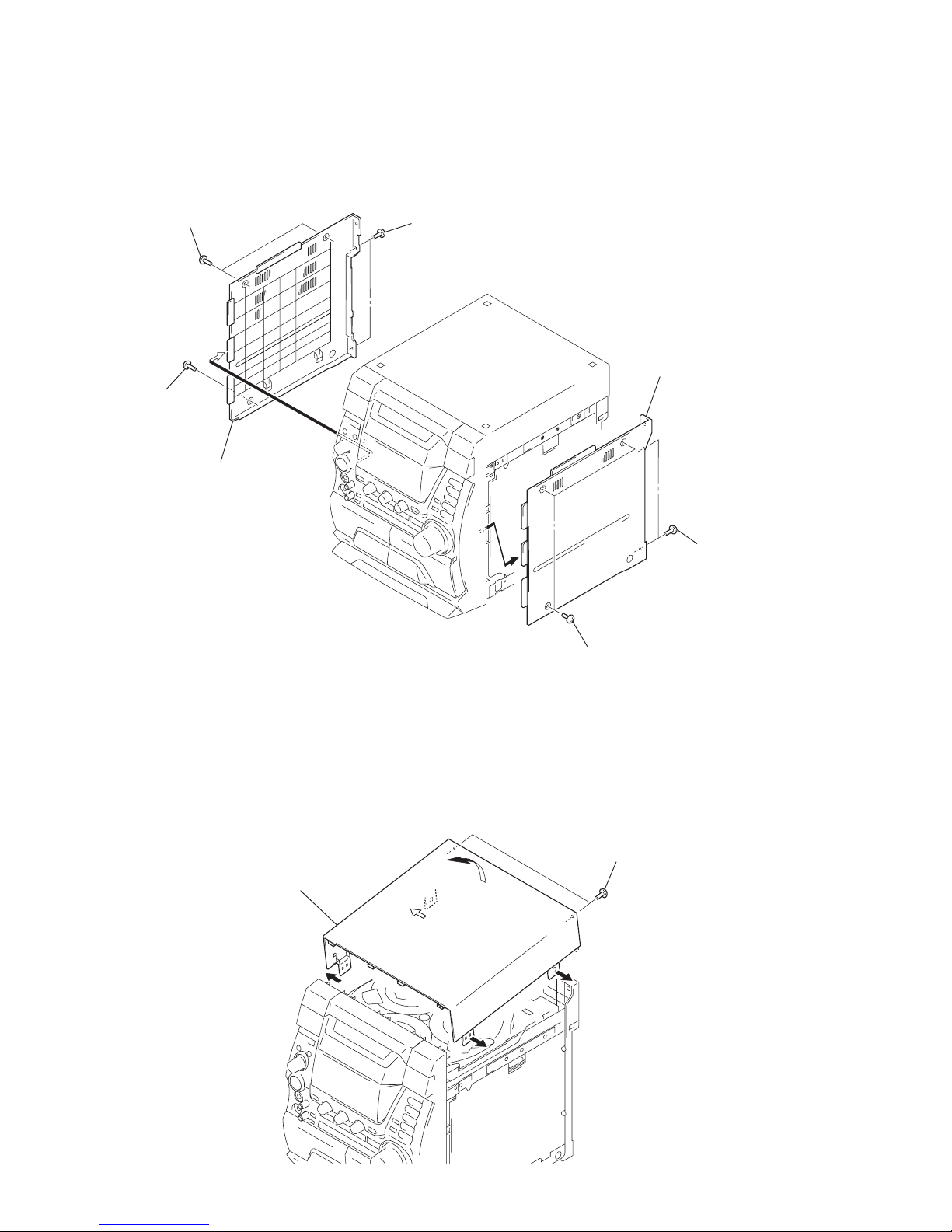

3-2. Case (Side-L/R) ............................................................... 10

3-3. Case (Top) ....................................................................... 10

3-4. Tray Panel........................................................................ 11

3-5. CD Mechanism Deck (CDM74-K4BD49) ...................... 11

3-6. Front Panel Block ............................................................ 12

3-7. Back Panel Section .......................................................... 12

3-8. MAIN Board.................................................................... 13

3-9. Tape Mechanism Deck (CWM43FR36).......................... 13

3-10. Table Assy ....................................................................... 14

3-11. MOTOR (TB) Board ....................................................... 14

3-12. MOTOR (LD) Board ....................................................... 15

3-13. Base Unit (BU-K4BD49) ................................................ 15

3-14. BD49 Board..................................................................... 16

4. TEST MODE.............................................................. 17

5. ELECTRICAL ADJUSTMENTS

CD Section ...................................................................... 21

VIDEO Section................................................................ 22

6. DIAGRAMS

6-1. Block Diagram – CD SERVO Section – ........................ 23

6-2. Block Diagram – AUDIO/VIDEO CD Section – ........... 24

6-3. Block Diagram – MAIN Section – ................................. 25

6-4. Block Diagram

– PANEL/POWER SUPPLY Section – ........................... 26

6-5. Printed Wiring Board – BD49 Board – .......................... 28

6-6. Schematic Diagram – BD49 Board – ............................. 29

6-7. Printed Wiring Boards – CHANGER Section –............. 30

6-8. Schematic Diagram – CHANGER Section – ................. 31

6-9. Schematic Diagram – VMP43GY Board (1/2) –............ 32

6-10. Schematic Diagram – VMP43GY Board (2/2) –............ 33

6-11. Printed Wiring Board – VMP43GY Board –.................. 34

6-12. Printed Wiring Boards

– VCD CONNECT, VIDEO OUT Boards – ................... 35

6-13. Schematic Diagram

– VCD CONNECT, VIDEO OUT Boards – ................... 35

6-14. Schematic Diagram – MAIN Section (1/4) – ................. 36

6-15. Schematic Diagram – MAIN Section (2/4) – ................. 37

6-16. Schematic Diagram – MAIN Section (3/4) – ................. 38

6-17. Schematic Diagram – MAIN Section (4/4) – ................. 39

6-18. Printed Wiring Boards – MAIN Section – ..................... 40

6-19. Printed Wiring Board –PANEL Section – ...................... 41

6-20. Schematic Diagram – PANEL Section (1/2) – ............... 42

6-21. Schematic Diagram – PANEL Section (2/2) – ............... 43

6-22. Printed Wiring Board – POWERAMP Section – .......... 44

6-23. Schematic Diagram – POWERAMP Section – ............. 45

6-24. Printed Wiring Boards – TRANS Section – ................... 46

6-25. Schematic Diagram – TRANS Section – ....................... 47

7. EXPLODED VIEWS

7-1. Case Section .................................................................... 62

7-2. Tape Mechanism Deck Section ....................................... 63

7-3. Cassette Box Section ....................................................... 64

7-4. Front Panel Section ......................................................... 65

7-5. Back Panel Section .......................................................... 66

7-6. Chassis Section................................................................ 67

7-7. CD Mechanism Deck Section-1 (CDM74-K4BD49) ..... 68

7-8. CD Mechanism Deck Section-2 (CDM74-K4BD49) ..... 69

7-9. CD Mechanism Deck Section-3 (CDM74-K4BD49) ..... 70

7-10. Base Unit Section (BU-K4BD49) ................................... 71

8. ELECTRICAL PARTS LIST................................ 72