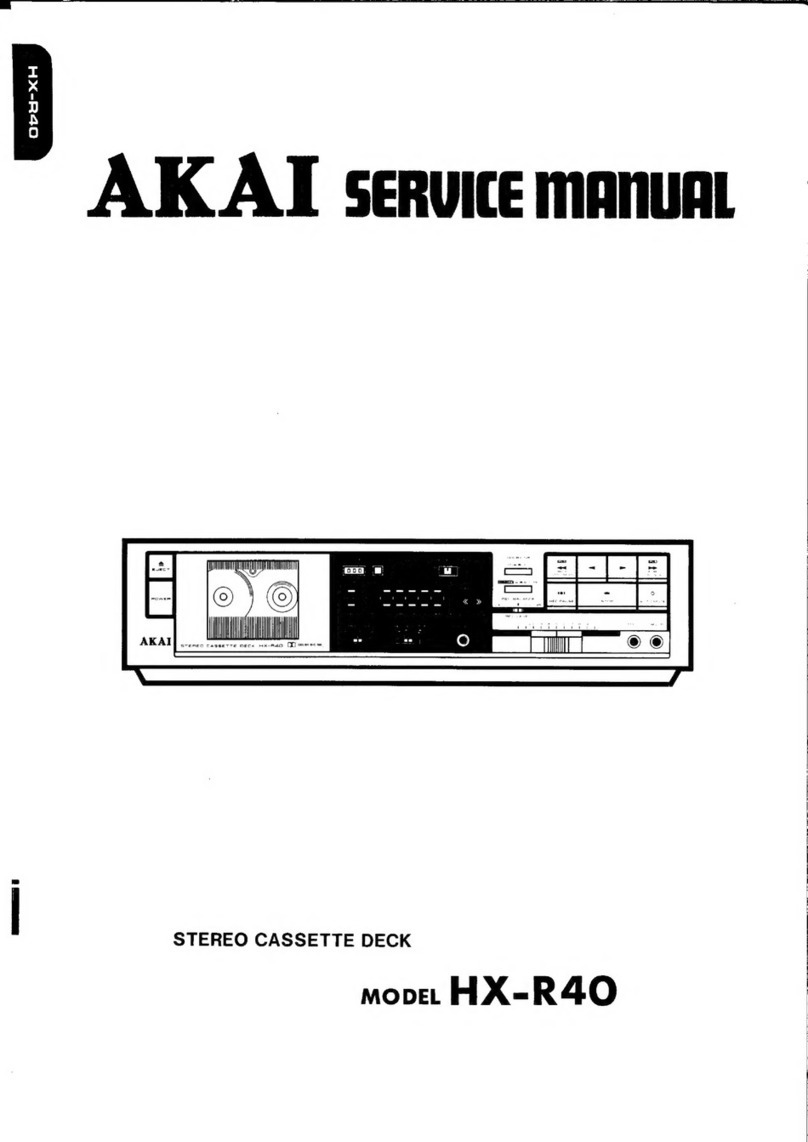

TI

LOCATION

OF

CONTROLS

SOUND

MIRROR

SPEED

CHANGE

&

ON/OFF

SWITCH

TOP

(DECK)

PANEL

TAKE-UP

REEL

SPINDLE

CAPSTAN

SHAFT

PINCH

ROLLER

CAP

PINCH

ROLLER

AUTOMATIC

SHUT-OFF

LEVER

INSTANT

STOP

LEVER

START

BUTTON

RECORD,

PLAY

SWITCH

REWIND,

FAST-FORWARD

SWITCH

RECORD

SAFETY

BUTTON

AUTO

STOP,

SHUT-OFF

SWITCH

RECORD/PLAY

HEAD

PILOT

LAMD

(RECORDING

INDICATOR)

INTERNAL

SPEAKER

ON/OFF

SWITCH

POWER

SWITCH

SPEAKER

OUTPUT

JACK

(LEFT)

TONE

CONTROL

(LEFT)

EQUALIZER

SWITCH

(LEFT)

VOLUME

CONTROL

(LEFT)

VOLUME

UNIT

METER

(LEFT)

SOUND

ON

SOUND

SWITCH

STEREO

HEADPHONE

JACK

FUNCTION

SWITCH

SPEAKER

OUTPUT

JACK

(RIGHT:

VOLUME

UNIT

METER

(RIGHT)

FEED

REEL

SPINDLE

GUARD

CIRCLE

weet

CYCLE

CONVERSION

SWITCH

CAPSTAN

STORAGE

POST

RETAINING

SCREW

TRACK

SELECTOR

KNOB

TAPE

GUIDE

ROLLER

’

TAPE

CLEANER

RELEASE

BUTTON

HEAD

COVER,

MAIN

ERASE

HEAD

INDEX

(REVOLUTION)

COUNTER

RESET

BUTTON

CROSS-FIELD

HEAD

DIN

(ONE

CONNECTION)

JACK

DICE

LD

INDUT

(LEET

CHANNET)

PRE-AMP

OUTPUT

(LEFT)

LINE

INPUT

(LEFT)

MICROPHONE

INPUT

(LEFT)

PICK

UP

INPUT

(RIGHT

CHANNEL)

PRE-AMP

OUTPUT

(RIGHT)

LINE

INPUT

(RIGHT)

MICROPHONE

INPUT

(RIGHT)

VOLUME

CONTROL

(RIGHT)

EQUALIZER

SWITCH

(RIGHT)

TONE

CONTROL

(RIGHT)

CARRYING

CASE

YHGFOHOSCBHOSHSOSHOSOOQQOGHOHOOO

SEDHOGHHHHHGHHHOOHOPHSHOLOGOLHO®