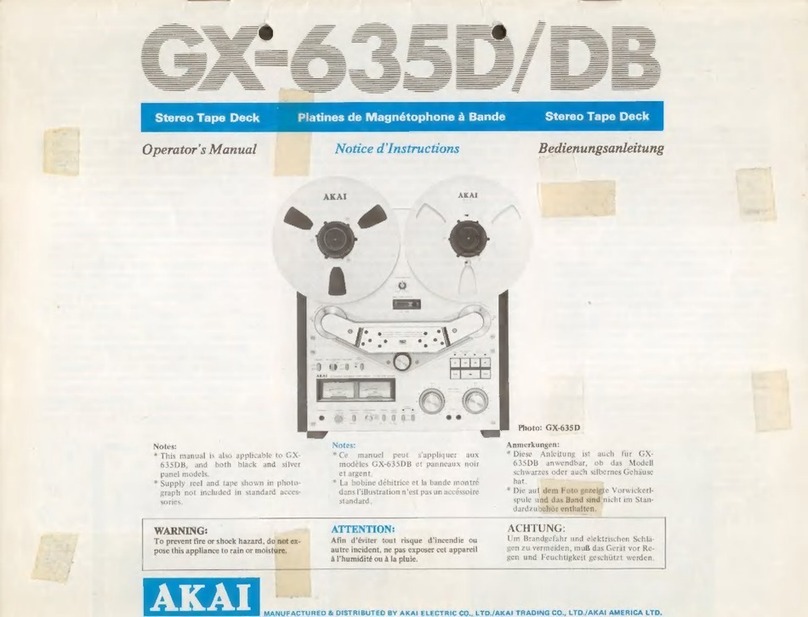

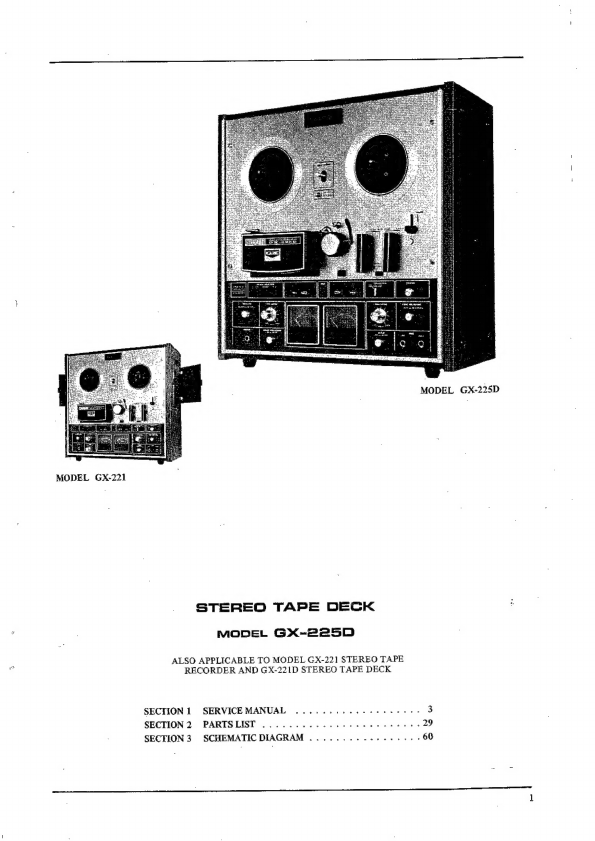

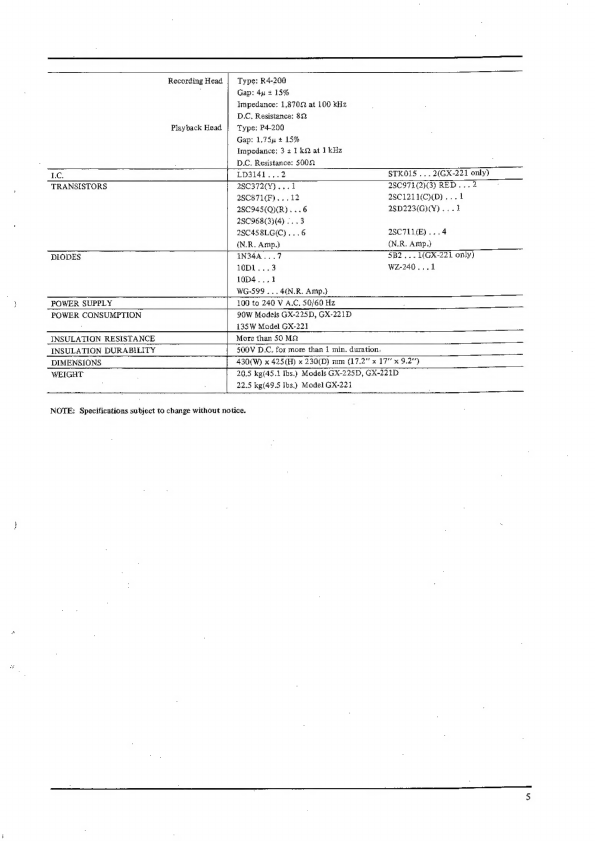

Akai GX-225D User manual

Other Akai Tape Deck manuals

Akai

Akai GX-400D User manual

Akai

Akai GX-270DSS Troubleshooting guide

Akai

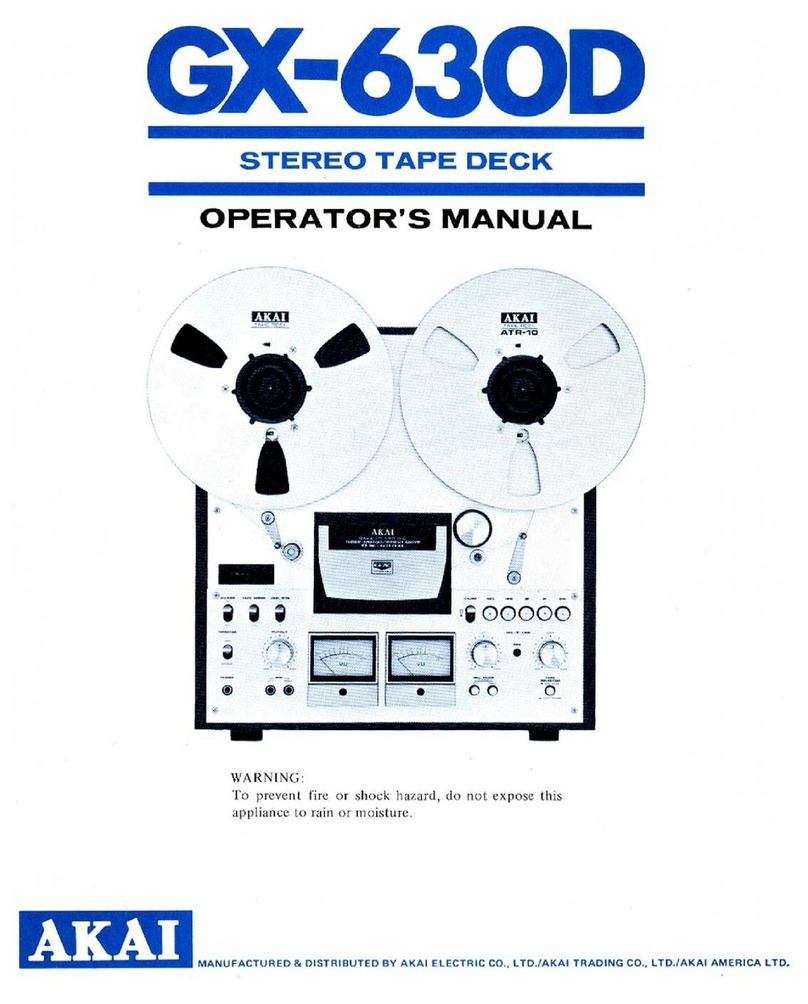

Akai GX-630D Troubleshooting guide

Akai

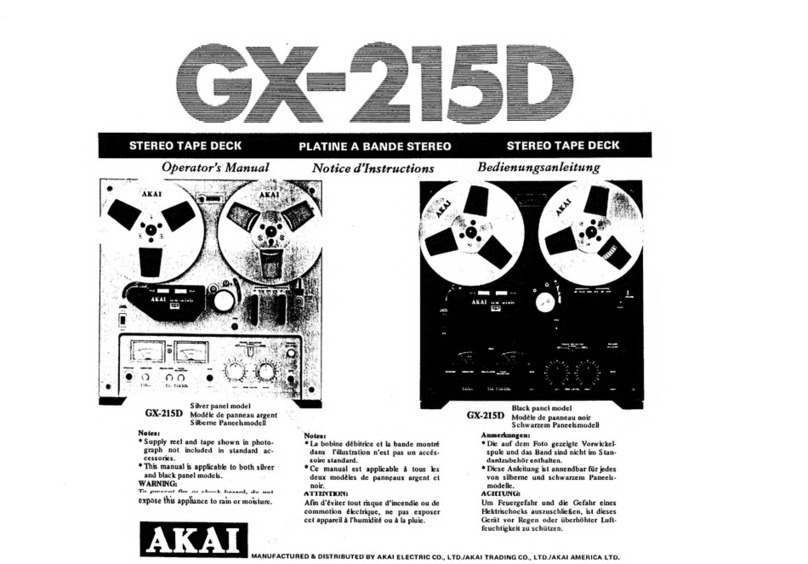

Akai GX-215D User manual

Akai

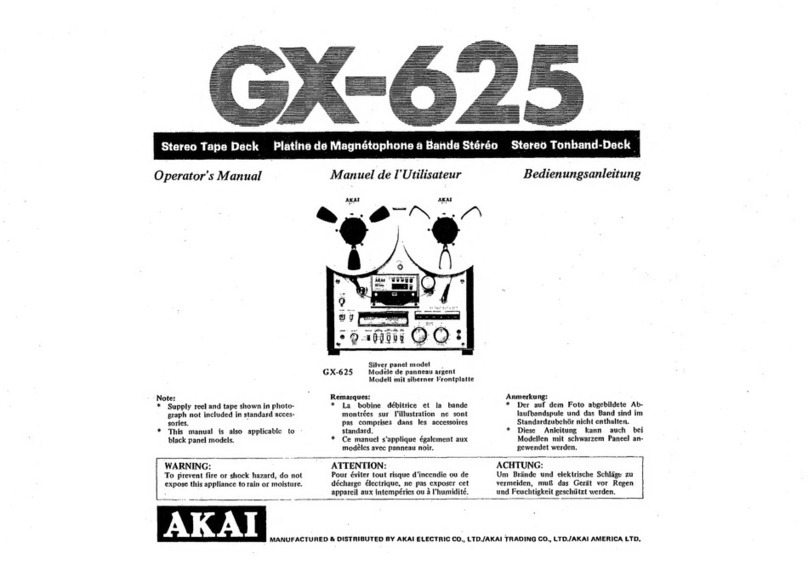

Akai GX-625 User manual

Akai

Akai GX-230D User manual

Akai

Akai GX4000D Troubleshooting guide

Akai

Akai GX-630D User manual

Akai

Akai GX-77 User manual

Akai

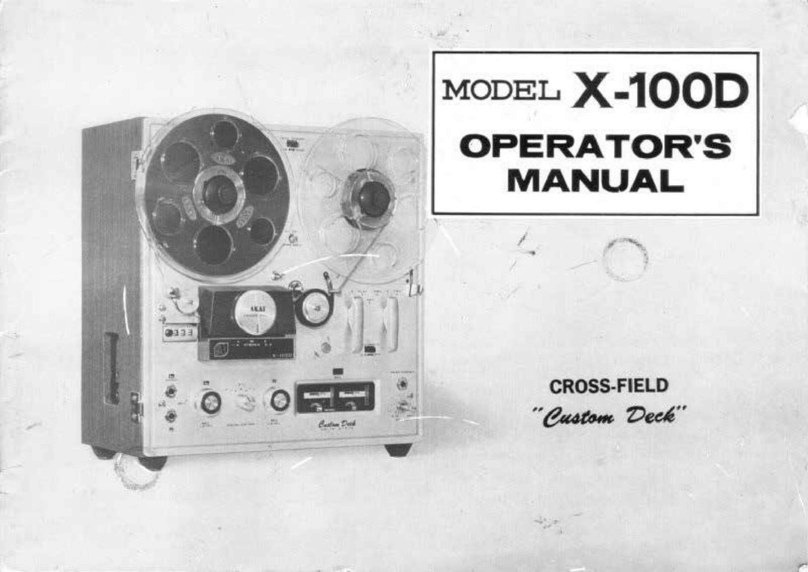

Akai X-100D User manual