Akai GX4000D Troubleshooting guide

Other Akai Tape Deck manuals

Akai

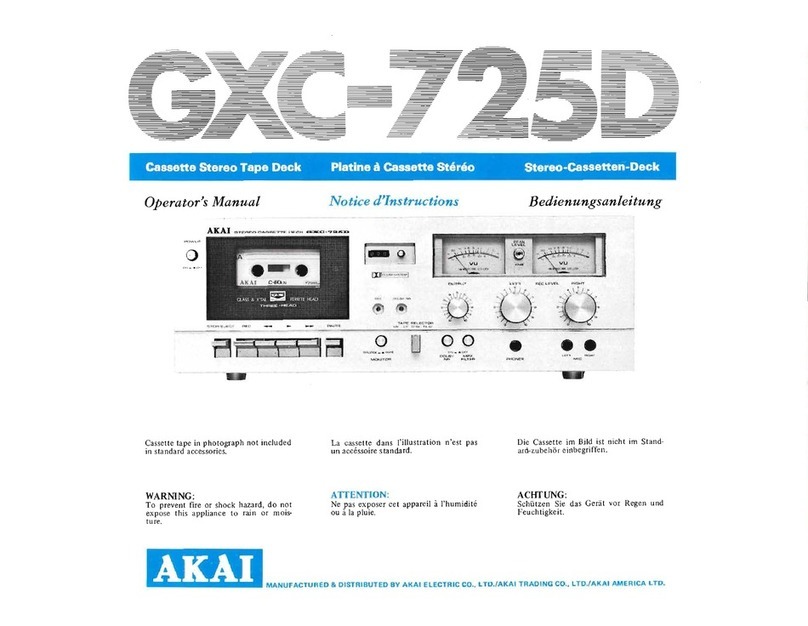

Akai GXC-725D User manual

Akai

Akai GX-230 User manual

Akai

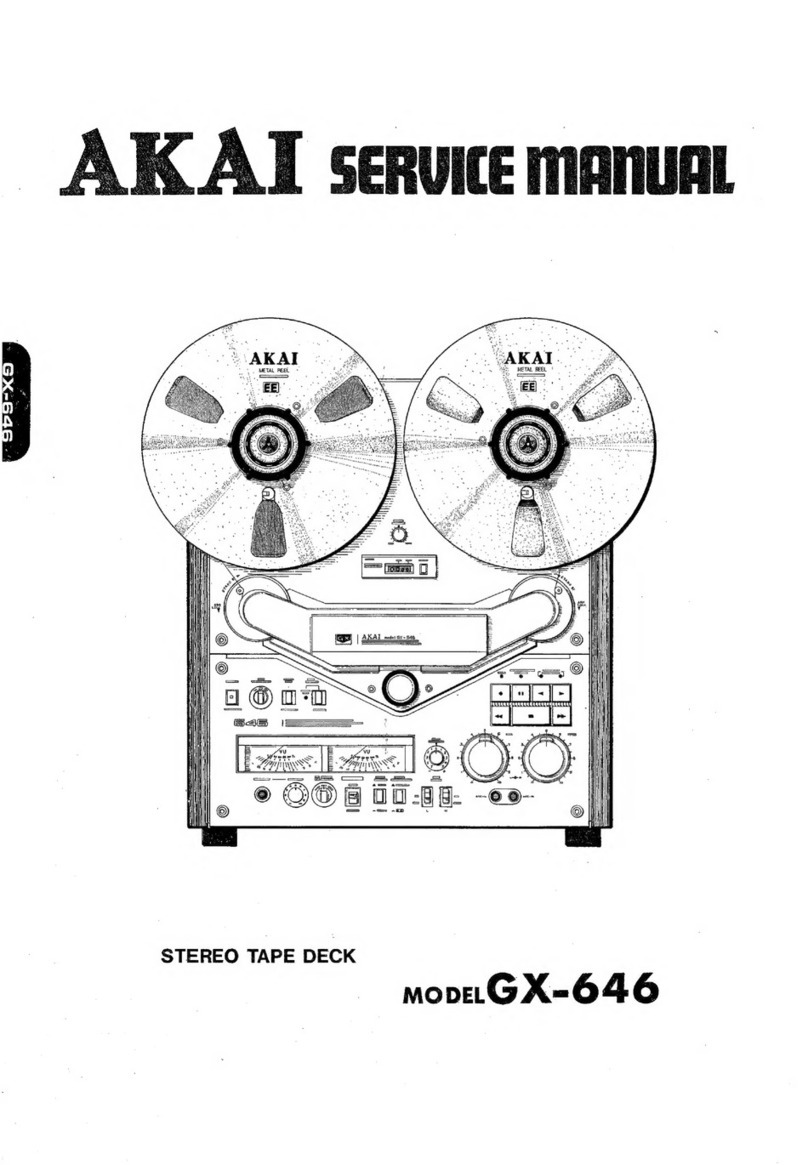

Akai GX-646 User manual

Akai

Akai 4000DS Mk-II User manual

Akai

Akai GX-365D User manual

Akai

Akai GX-270DSS Troubleshooting guide

Akai

Akai GX-210D Operating and installation instructions

Akai

Akai GXC-710D User manual

Akai

Akai GX-747 User manual

Akai

Akai X-2000 User manual