SECTION

1

SERVICE

MANUAL

TABLE

OF

CONTENTS

L

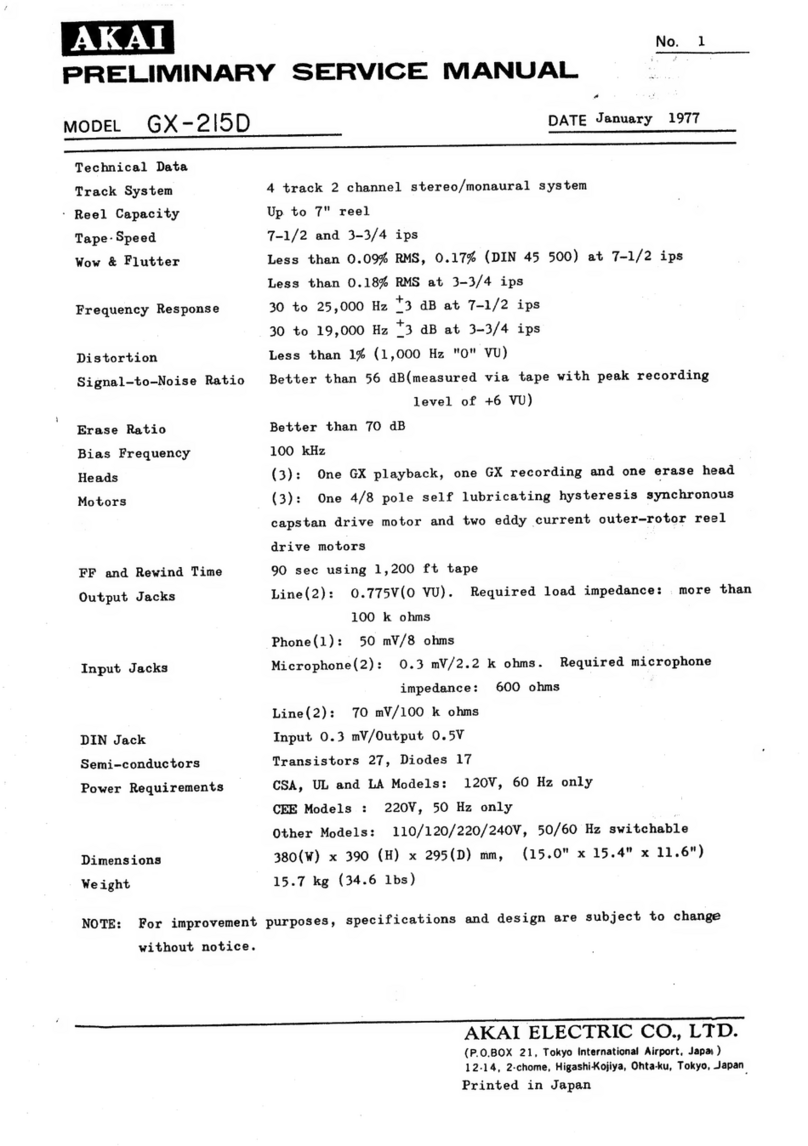

SPECIFICATIONS

*

i

i5hsshatiscichsssctaceh

hess

acesstescttis

sas

caanes

Meaveccaseesoibeves

thensardanatech

edetivcbiniadees

eee

Il.

DISMANTLING

OF

UNIT

III.

ARRANGEMENT

OF

PRINCIPAL

PARTS.

.u.....ccccccessssesssesesseseeseseserecsesenenenensesecessesnenseaeeeeeeaseesinaeess

7

IV.

MECHANISM

ADJUSTMENT.

............:cccccsscccsssessssescsscsessssscssesssseeseseesesesssenecssssseecseseesreseseeeeseeesssenecarsesanes

8

POSITION

ADJUSTMENT

OF

PINCH

WHEEL

SOLENOID

SL-3

o...sesssscsecsssessseesesseeteeseeneeeees

PINCH

WHEEL

POSITION

ADJUSTMENT

AT

STOP

MODE

_

.uw..seccceseeeeesstseersseaeeeneenenerene

PINCH

WHEEL

PRESSURE

ADJUSTMENT

...---sssssesssssssssessseersesesenesesesenees

POSITION

ADJUSTMENT

OF

PLAY

HOLD

MICROSWITCH

SW-11

SLIDE:

ADJUSTMENT

|

corsscssnsscerccosstcconcosssnssosnsestsnosocssvesncneiesignaasasoovbsnsdcvessessedenst

POSITION

ADJUSTMENT

OF

QUICK

PLATE

oesssscesssessesseeesseesseerecesseseneaereeseenesesesnesenerieansennes

POSITION

ADJUSTMENT

OF

RECORDING

MICROSWITCH

SW-5

POSITION

ADJUSTMENT

OF

BRAKE

SOLENOID

SL-2

oseseseessesesssestseeeeseessneessesereeeesenenenens

9,

POSITION

ADJUSTMENT

OF

BRAKE

SOLENOID

MICROSWITCH

SW-8

.......sseeeee

cette

11

10.

BRAKE

TENSION

ADJUSTMENT.

.......::c:cscccsssssesesessessssssssssesesessseseseneneneseseusseecsnseaeenensereeeseerasesenanes

11.

PAUSE

ADJUSTMENT

.u..scsccccccssssssecscesssssesessssesencsesensneeesensseseneeseseaeenesesnneenensaes

tissasscguegnaueaadvnciestseess

12.

POSITION

ADJUSTMENT

OF

REVERSE

SOLENOID

SL-1

ooesessesssseesssseesssesesesesseeneeeneeeenenenes

13.

D

SWITCH

LEVER

ADJUSTMENT

......:..:::c:csssessssessetsseeeseteeeeseeerseeeseaesens

14.

INSTALLATION

POSITION

ADJUSTMENT

OF

REVERSE

JOINT

o..-sesssecseeeseseteteseneeenes

15,

INSTALLATION

POSITION

ADJUSTMENT

OF

HEAD

SWITCH

SW-3

16.

CAPSTAN

SHAFT LOOSE

PLAY

ADJUSTMENT

osesesssssssessecssssssesesesseesesseessaesensasasseceseneanneerngns

17.

OPERATING

POSITION

ADJUSTMENT

OF

TENSION

MICROSWITCH

SW-14

18.

TAPE

GUIDE

HEIGHT

ADJUSTMENT.

.....csccccscessscssesesesesseseesesesenessersesesesesenenssseseesenseneceasens

19.

REEL

TABLE

HEIGHT

ADJUSTMENT

oosesssssssscssssssescssssssesstessscensesnecssecesnessvesnecsanssneeessensecsnsente

HEAD

ADJUSTMENT.

-sccisciseveis

ceased

vosxegeteds

soit

bh

ncseibe

hous

cacts

heaveeiesvzchecadeanetaecesasareccutqua

de

aanenvassiansecenteeceeresdoee

AMPLIFIER

SYSTEM

ADJUSTMENT

.....-:::cccccccccccecceeeeescscncescessessscnensnnneeeneceneesecessesnaceecseseersceeacaserteseeeeses

1.

DC

POWER

SUPPLY

VOLTAGE

ADJUSTMENT.

-----s:sesesesee

Sadan

bedverddabaveieivvsrdl

deevns

seed

2.

TAPE:

SPEED

ADJUSTMENT.

cisicciestisicceccssscclesertiasacesadsnnsadnesenstedevencteeapescnancensoesendescnenasctnandecdetiedeedes

3.

RECORDING

AND

PLAYBACK

AMPLIFIER

ADJUSTMENT

.u.-s.ccesscccscesssesstetenntee

se

eeseeeenacenes

VII.

DC

RESISTANCE

OF

VARIOUS

COILS

ou.ccescccccssssessccssseseseesssesesecescenceescssedeseseseeeeeeaeseseseneraena

ee

sensnssenenss

VIIT.

CLASSIFICATION

OF

VARIOUS

P.C

BOARDS

oveseseeececeecssesesessseesereseneeneeesenseseseseseeseneaesnsg

eee

ciesenenenees

1.

RELATION

OF

P.C

BOARD

TITLE

AND

NUMBER

...s...eeccecsccsssesssesteeeeeeteetecnseecssennses

oe

eeersnersnenes

2.

COMPOSITION

OF

VARIOUS

P.C

BOARDS

.

0...

ce

cceeceesececereeesseesesseecssessaersseecesaeesneneneeaessanesseaees

SN

AARwWH

<<

For

basic

adjustments,

measuring

methods,

and

operating

principles,

refer

to

GENERAL

OPERATING

PRINCIPLES

AND

ADJUSTMENTS.

|

|

|

|

|

|

|