Akai ABTS- M10 User manual

Other Akai Tape Deck manuals

Akai

Akai GX-77 User manual

Akai

Akai GX-646 User manual

Akai

Akai GXC-725D User manual

Akai

Akai GX-210D Operating and installation instructions

Akai

Akai GX-625 User manual

Akai

Akai GX-646 User manual

Akai

Akai GX-210D User manual

Akai

Akai 1722W User manual

Akai

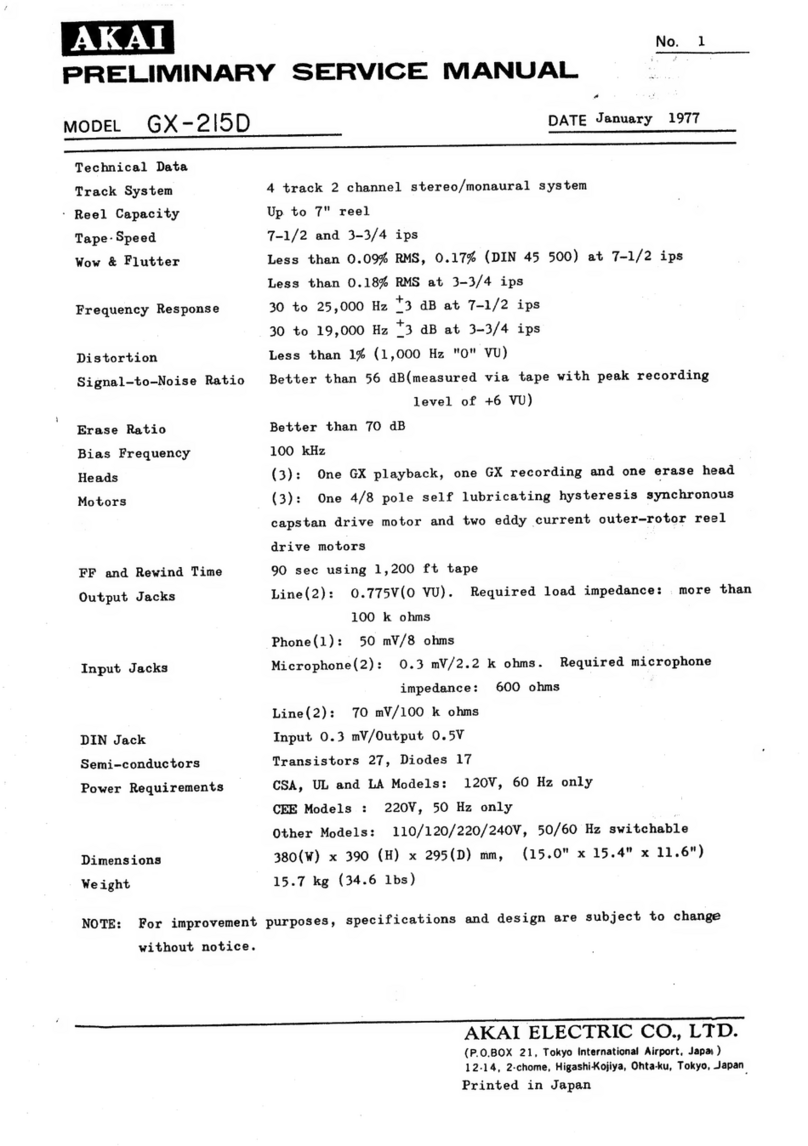

Akai GX-215D User manual

Akai

Akai GX-266D User manual