AKO Electromecánica thanks and congratulates you for purchasing our product, in whose development and manufacture the most

innovative technology has been used, as well as strict production and quality control processes.

Our commitment to satisfy our customers and our continuous efforts to improve every day can be seen in the various quality certifi-

cations we have obtained.

This is a high performance, high technology product. The operation and final performance of the equipment depend on proper plan-

ning, installation, configuration and commissioning. Read this manual carefully before installation, and always follow its instructions.

Only qualified personnel should install or perform technical assistance on this product.

This product is designed to be used in the applications described in the product manual. AKO Electromecánica gives no guarantee

of its operation in any use not foreseen in the manual, and is not responsible for any damage resulting from improper use, configu-

ration, installation or commissioning.

It is the responsibility of the installer and the customer to comply with and ensure others comply with all regulations applicable to

installations incorporating our products. AKO Electromecánica is not responsible for any damage caused by non-compliance with re-

gulations. Follow strictly the instructions given in this manual.

To maximise the service life of our equipment, these recommendations should be followed:

Do not expose electronic equipment to dust, dirt, water, rain, humidity, high temperatures, chemicals or corrosive sub-

stances of any sort.

Do not submit the equipment to blows or vibrations nor try to manipulate it differently from shown in the manual.

Never exceed the specifications and limitations indicated in the manual.

Always respect the specified ambient working and storage conditions.

During and after installation, avoid leaving loose, broken, unprotected or damaged wiring, since they might constitu-

te a risk for the equipment and its users.

AKO Electromecánica reserves the right to make any non-metrology modification to the documentation or the equipment without

previous notice.

Contents Page

Chapter 1: Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Chapter 2: Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

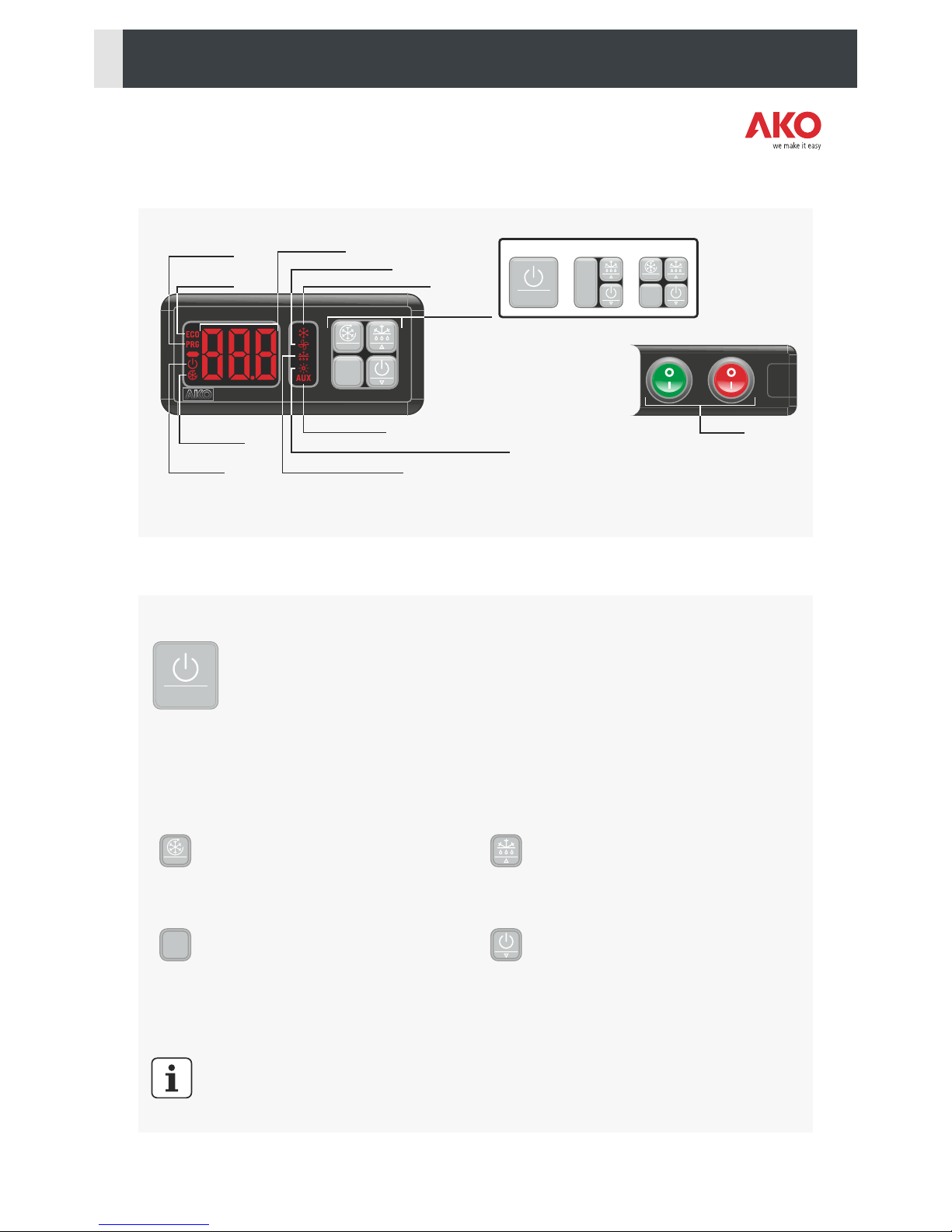

2.1 Keypad functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

2.2 Display messages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

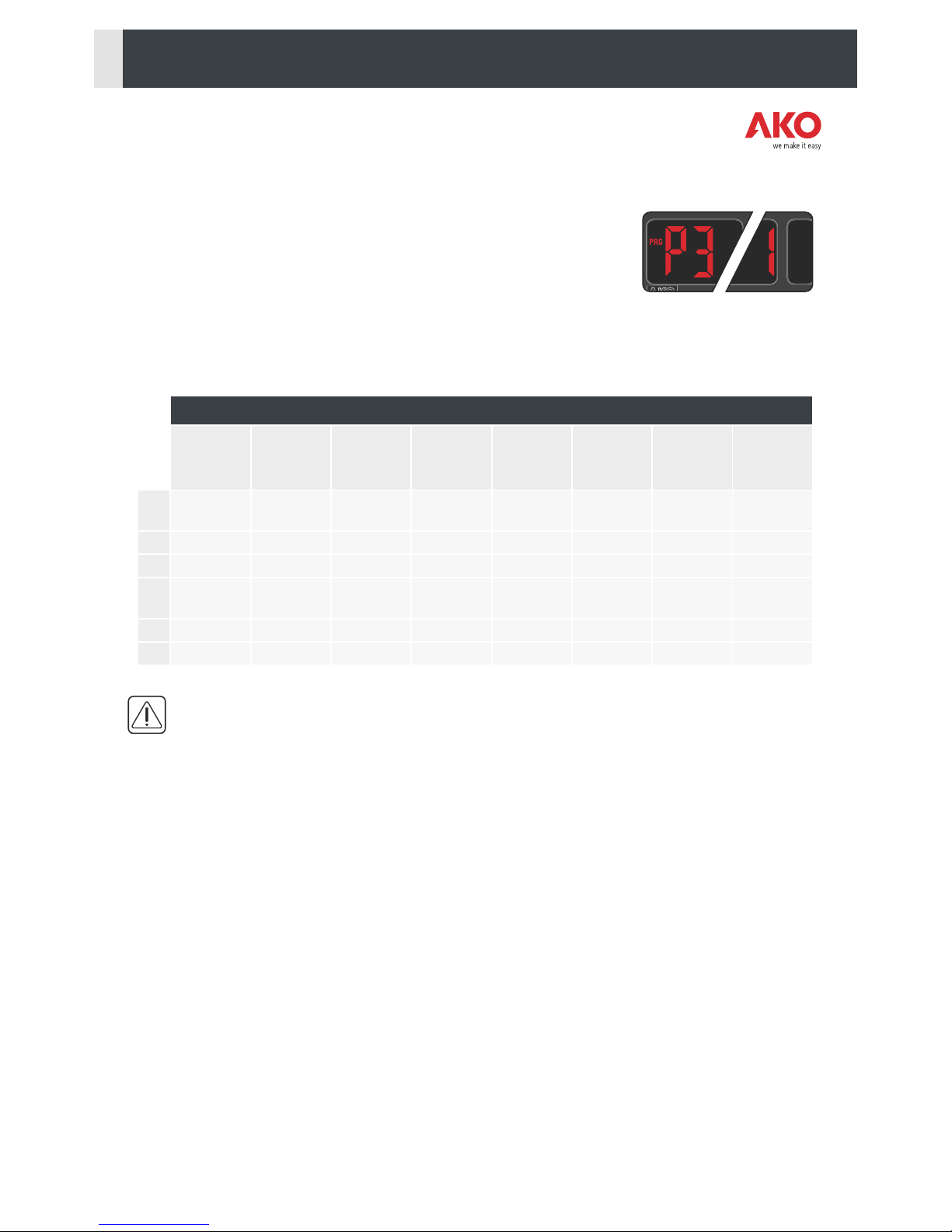

2.3 Versions and . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

2.4 Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

2.5 Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Chapter 3: Initial Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

3.1 Wizard (not available in thermometers) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

3.2 Basic settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Chapter 4: Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

4.1 Compressor control (not available thermometers) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

4.2 Defrost control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

4.3 Fan control (only controllers with two or more relays) . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

4.4 Light control . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

4.5 Pump Down function (only four-relay controllers) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

4.6 Alarms . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Chapter 5: Wiring. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

5.1 Thermometers. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

5.2 1-relay controller . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

5.3 .......................................................20

5.4 .......................................................20

5.5 .......................................................21

Chapter 6: Connectivity . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Chapter 7: Parameter setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

7.1 Programming Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

7.1.1 Changing the set point (not available in thermometers). . . . . . . . . . . . . . . . . . 22

7.1.2 Changing the operating parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

7.1.3 Parameters. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

8. Technical Specifications. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

part numbers

in

(not available thermometers)

(only controllers with two or more relays)

2-relay controller

3-relay controller

4-relay controller

in

2