General: 01905 823 298 | www.akw-ltd.co.uk8

8

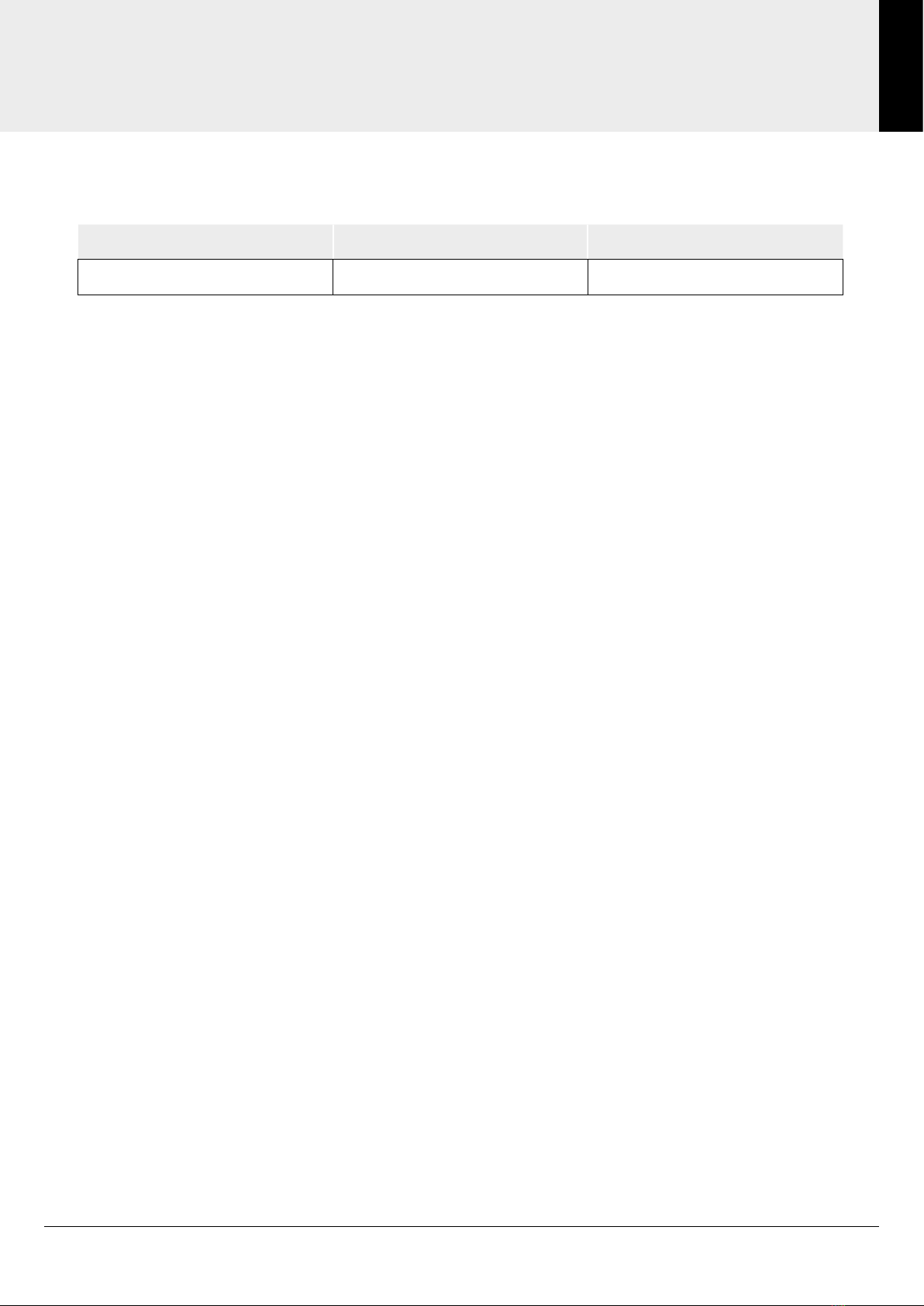

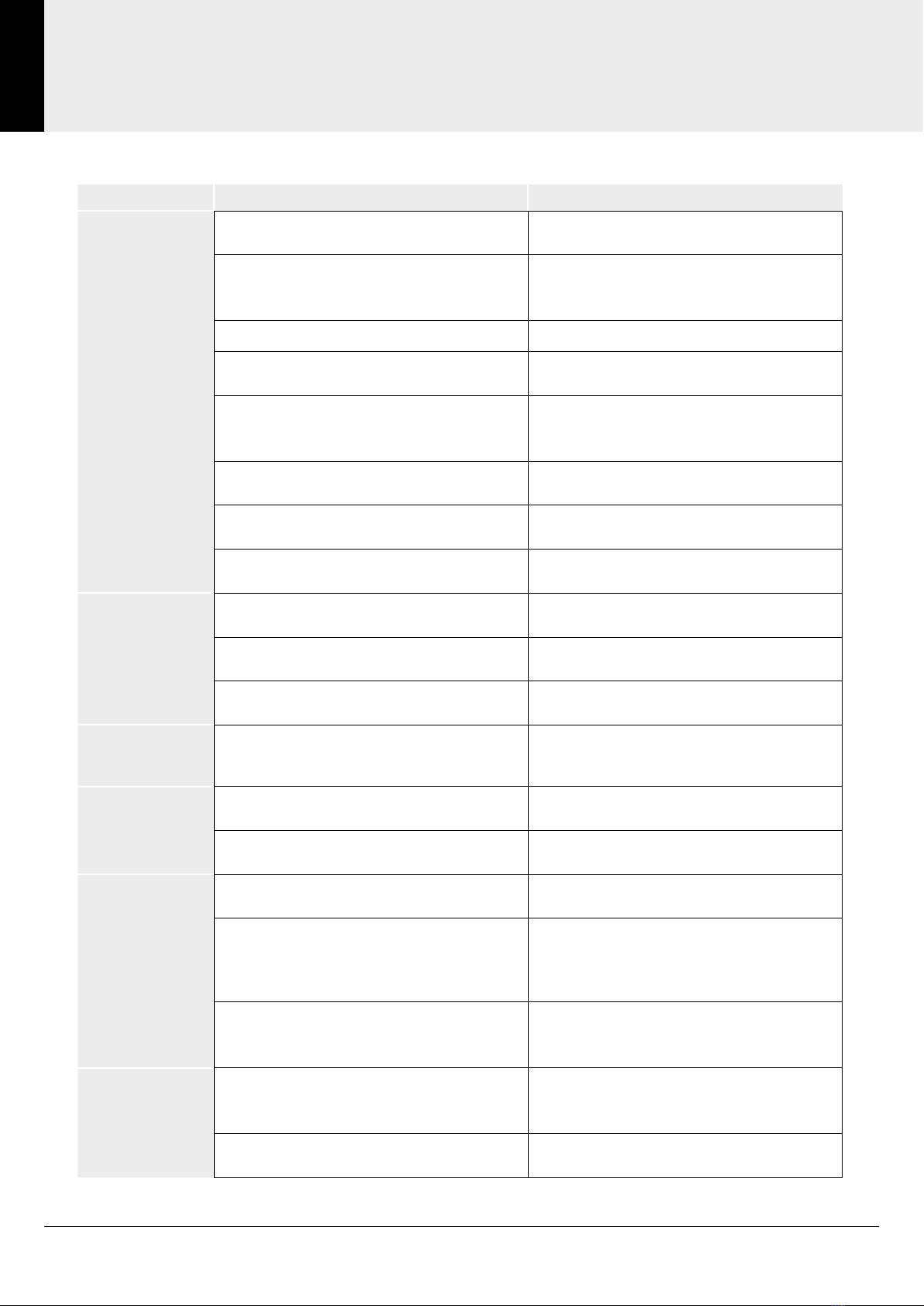

TROUBLESHOOTING

Troubleshooting

Problem Cause Solution

No flow or low

flow rate and

/ or varying

temperatures

Partially closed stop or service valve in

water supply pipework to the mixer valve. One stop or service valve.

Instantaneous water heater cycles on and

off as the flow rate or pressure is too low.

Increase water flow rate

or pressure through system.

Contact the boiler manufacturer.

Head of water is below the minimum required Refer to specifications section.

Inlet filter is partially blocked. Clean or replace. Flush pipework

before refitting.

Hot or cold water being drawn off

elsewhere causing pressure changes

or instantaneous boiler changes.

Do not use other water outlets when using

the shower valve.

Imbalanced inlet pressures. If pressures are unbalanced a pressure

reducing valve should be used.

Airblock or partial blockage of the pipework. Flush pipework to ensure removal

of debris and any airlocks.

No hot or cold water reaching

the shower valve.

Check hot and cold feeds (the valve will

shut down if either supply fails.

Water leaking

from shower

head

This is normal for a short time

after turning off.

Adjust the angle of the shower head as

necessary to vary draining time.

Shower flow control valve failing to close

fully, possibly due to water borne debris.

Remove flow control valve

assembly and check.

Flow control valve seals damaged. Check condition of flow control valve

and replace as necessary.

Maximum water

temperature is

too hot or cold

Maximum water temperature

is set incorrectly Reset maximum water temperature.

Outlet water

temperature is

too hot or cold

Inlet filter is partially blocked. Check inlet filters for any blockages

and clean as necessary.

Installation conditions are outside

operating parameters. Refer to Important Information section.

Water supply

temperature is

too cold

Hot water temperature is less than 10 °C

above the required blend temperature.

Adjust hot water temperature or wait for

water to reheat if stored system is used.

Instantaneous water heater is not igniting

because water flow rate is too low.

Increase water flow rate through the system.

Check cartridge inlet filters

and clean or replace.

Contact the manufacturer.

Instantaneous water heater is not igniting

because water pressure is too low.

Refer to Information for system requirements.

Increase water pressure through system.

Contact the manufacturer.

Only hot or cold

water from

TMV outlet.

Inlet water supplies are reversed (hot to

cold supply).

Connect the water supplies correctly. Hot on

the left and cold on the right when viewed

from the front. Rework pipework as necessary.

Inlet filter is partially blocked. Clean or replace. Flush through

pipework before refitting.