REF: WM4 Service WI V18.docx Page 2 © Alcolizer Technology

Uncontrolled when printed

Contents

1Competency Requirements ...............................................................................................4

2Risks/ Safety.......................................................................................................................4

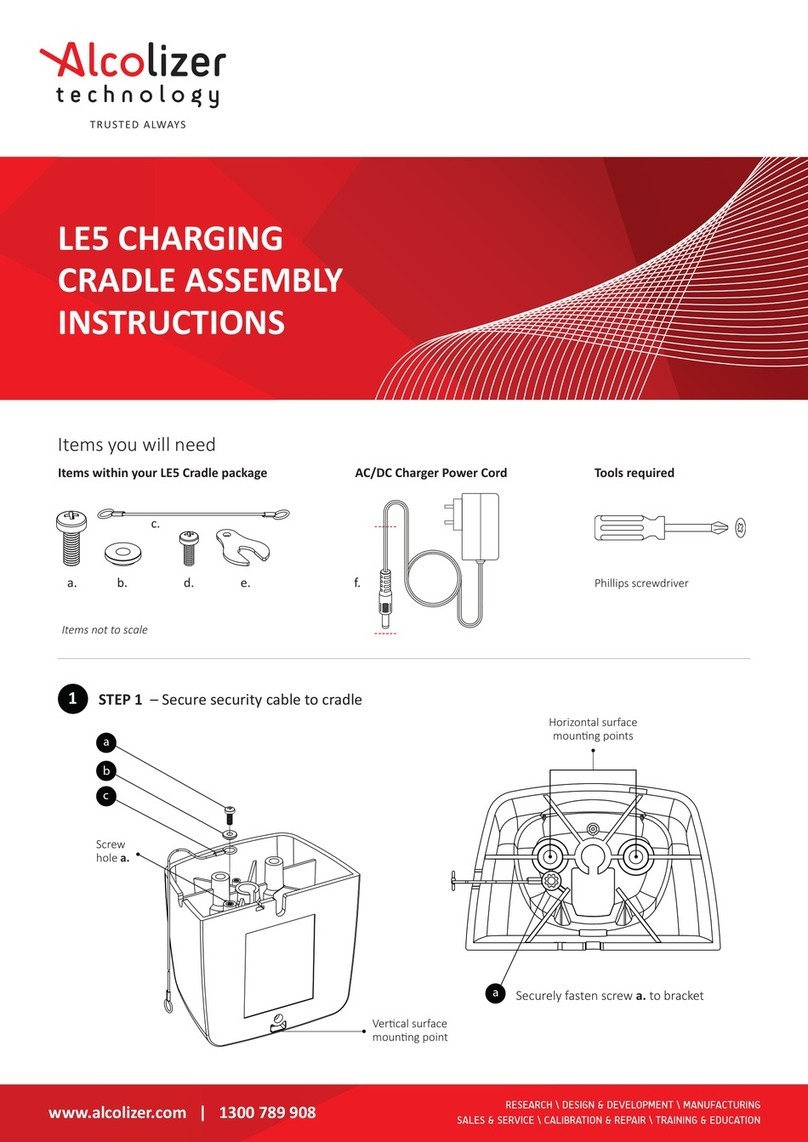

3Equipment..........................................................................................................................4

4Service Procedure ..............................................................................................................5

4.1 Visual Inspection (Mandatory)....................................................................................5

4.1.1 Electrical Safety....................................................................................................5

4.1.2 General Defects and Wear and Tear....................................................................5

4.2 Backup Battery ............................................................................................................5

4.2.1 9 Volt Battery.......................................................................................................5

4.2.2 Rechargeable Battery Pack ..................................................................................6

4.3 Instrument Upgrade....................................................................................................6

4.3.1 Prior to Upgrade - All Instruments.......................................................................7

4.3.2 Prior to Upgrade - Releases AC-5.0 to AC12.1.....................................................7

4.3.3 Via SD Card...........................................................................................................7

4.3.4 Upgrade Coprocessor (ONLY IF UPGRADING BETWEEN AC-5 AND AC-12.1)......8

4.3.5 Upgrade SOM after the Coprocessor...................................................................9

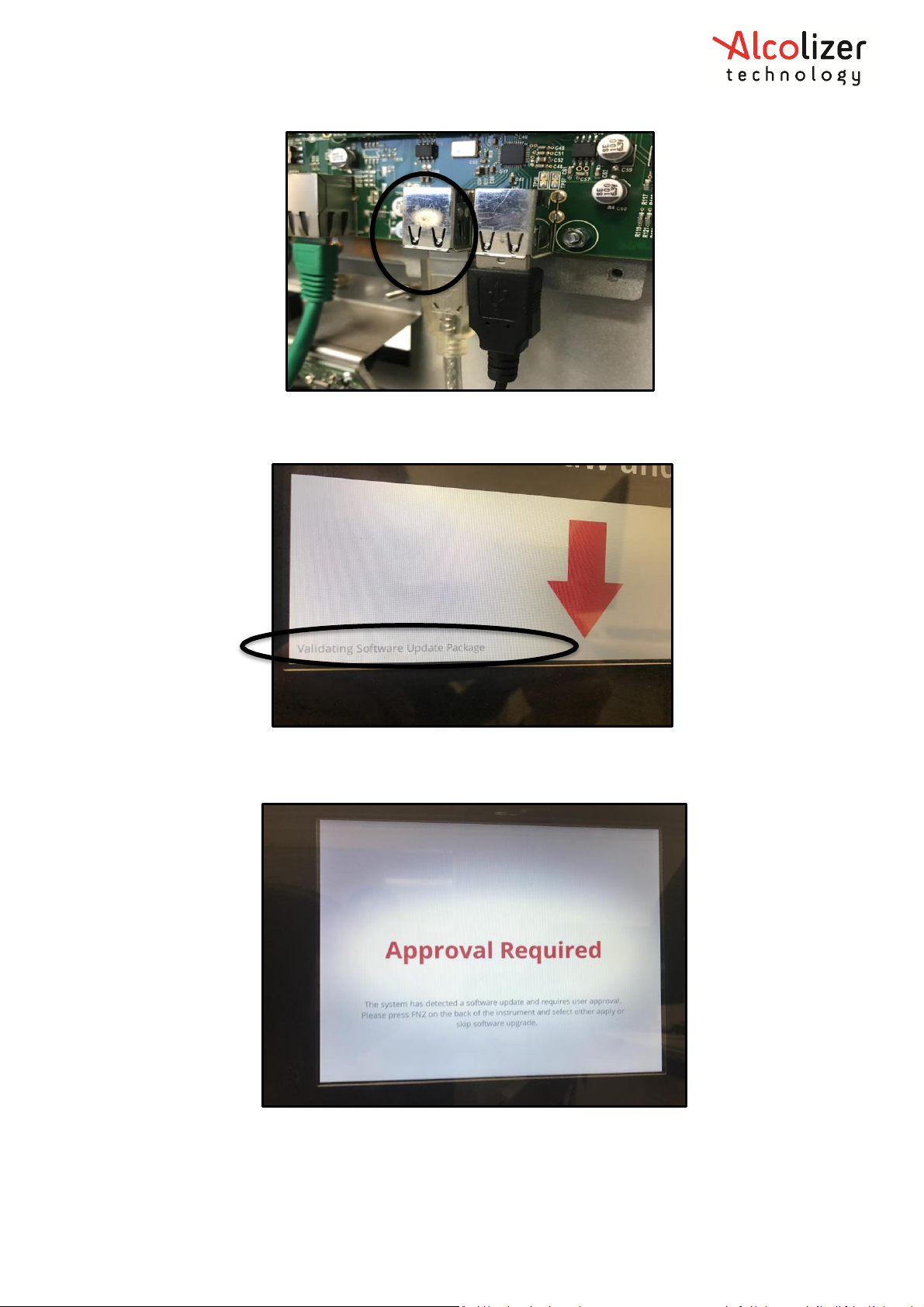

4.3.6 Via USB.................................................................................................................9

4.3.7 Validate Migration of Settings ...........................................................................13

4.4 Gas Bottle Replacement............................................................................................14

4.5 Operation Testing (Mandatory) ................................................................................15

4.6 Leak Test....................................................................................................................15

4.6.1 Procedure...........................................................................................................16

4.7 Cleaning.....................................................................................................................19

4.8 Sample System Replacement....................................................................................20

4.9 Customise Instrument...............................................................................................21

4.9.2 Camera...............................................................................................................23

4.9.3 Camera Diagnostic .............................................................................................24

4.9.4 Coin ....................................................................................................................24

4.9.5 Coin Diagnostic ..................................................................................................24

4.9.6 Wiegand.............................................................................................................24

4.9.7 Printer ................................................................................................................28

5Rentals..............................................................................................................................29

6Packing Instruction...........................................................................................................29

7QUICK GUIDE....................................................................................................................31