SER 8072-A Diesel Exhaust Fluid (DEF) Reel

Revision (11-12) 2

lemite LLC

Personal

S

a

fe

t

y

Personal injury and/or equipment damage may result if

proper safety precautions are not observed.

WARNING

• Even low pressure can cause irreparable

damage or death. Exercise extreme

caution while operating or servicing this

equipment.

• Do not use reel at higher pressures or

temperatures than listed in specification

table below.

• Ensure that reel is properly installed

before connecting supply line (see

instructions).

• Before connecting supply line to reel,

ensure that supply line pressure does not

exceed maximum rated working pressure

of reel.

• Do not wear loose fitting clothing while

operating reel.

• Be aware of other personnel/machinery in

work area.

• If a leak occurs in hose or reel, remove

supply line pressure immediately.

• Pull hose by grasping the hose itself not

by the dispense nozzle.

• If reel ceases to unwind or rewind

properly, remove power immediately. Do

not pull or jerk on hose. Find and remedy

problem before continuing.

• Treat and respect a hose reel as any other

piece of machinery, observing all

common safety practices.

• Release all pressure within the system

prior to performing any maintenance

procedure.

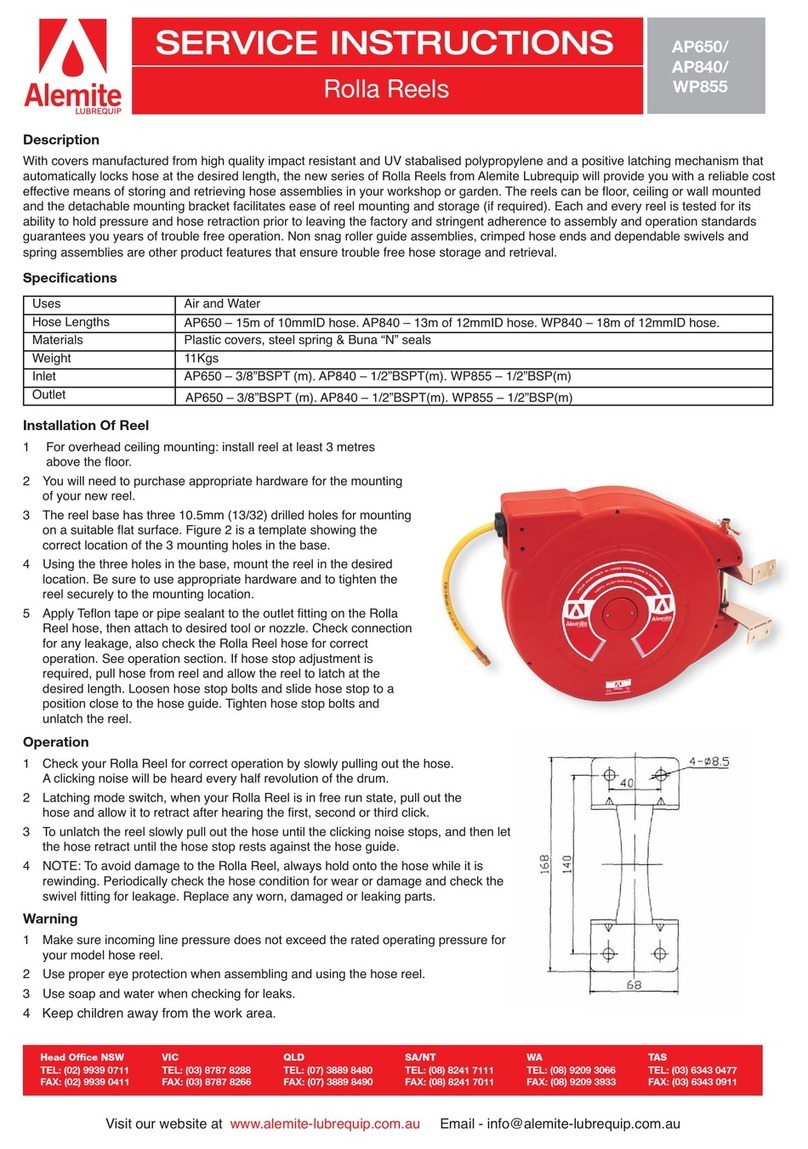

Specifications

MODEL DEF HOSE PRESSURE TEMPERATURE

8072-A ½” ID X 30’

[13mm X 9m] 300 psi

[21 bar]

-15˚F to 250˚F

[-26˚C to 151˚C]

8072-B ½” ID X 50’

[13mm X 15m]

CONNECTION

LOCATION THREAD TYPE

Hose Reel Inlet ½” BSPP (Female)

Hose Outlet ½” BSPP (Male)

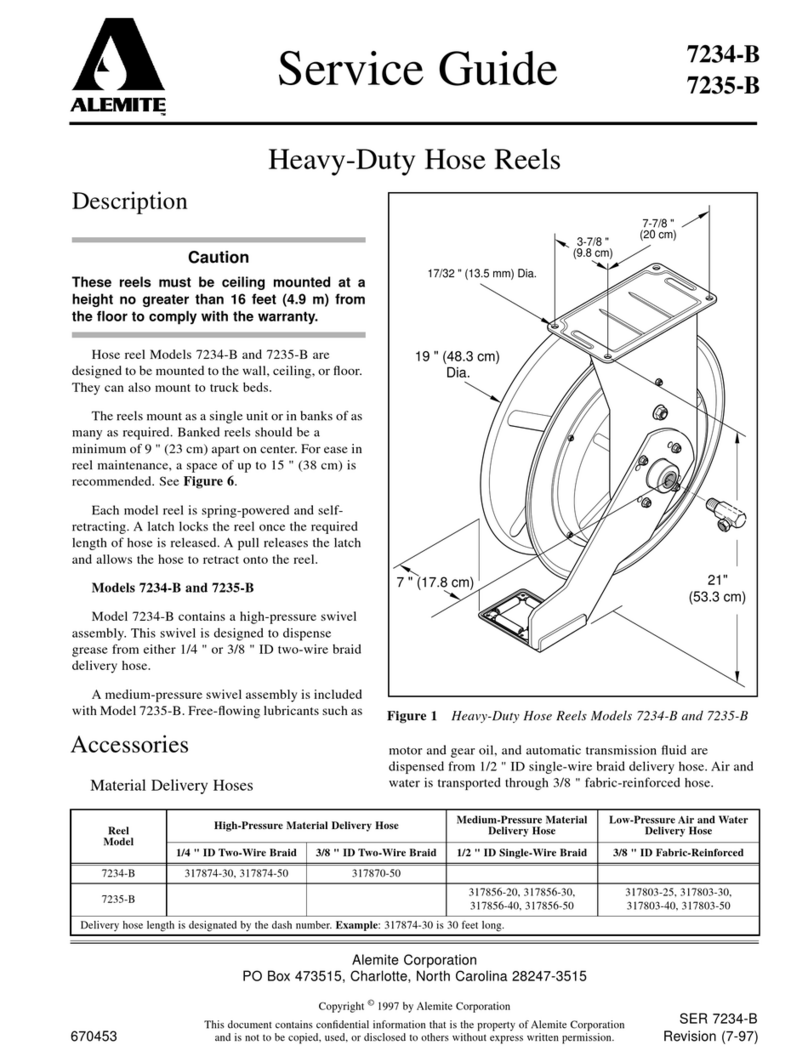

Description

These reels are designed to dispense Diesel Exhaust Fluid

(DEF) which is also known as aqueous urea solution 32 (AUS

32). DEF is a 32.5% solution of high-purity urea in de-

mineralized water which is injected into diesel engine exhaust

by a selective catalyst reduction (SCR) system to reduce

nitrogen oxide emissions. DEF must be stored, transported and

dispensed using approved materials which will not

contaminate the fluid. The wetted parts of these reels, the reel

shaft and swivel, are constructed from stainless steel and have

flouroelastomer seals. The dispense hoses included with the

reels feature an EPDM tube and cover with stainless steel

fittings. All of these components are constructed of materials

approved for use with DEF.

Installation

A flexible hose connection must be used between the hose

reel inlet and the source of supply to prevent possible

misalignment and binding. An inlet hose is not included

with this reel and must be ordered separately. Alemite

offers model 343143, a ½” ID x 2 ft. long DEF hose with

½” BSPP (Male) connector on each end.

M

o

un

t

i

n

g

The hose reel is equipped with a universal mounting

bracket so that it can be mounted on the floor, wall, or

ceiling; whichever place is convenient. The hose guide arm

can be moved to the position desired by removing the nuts

fastening the guide bracket to the reel base. Shift the guide

arm bracket so the hose comes off the reel at the desired

position and replace the nuts. Refer to Figure 2 for

dimensional drawing.