Flow rate: Up to 60L/min

Operating pressure (Max): 50psi (3.5bar)

Operating temperature: -10ºC ~ 60ºC

Accuracy: ±1%

Fluid type: Diesel, petrol & kerosene

Digital Screen:

5-Digit present total (0.01~999.99)

7-Digit non-resettable total (1~9999999)

Units - Litres, gallons, pints, quarts

Inlet and Outlet: 1" BSP swivel inlet & 19mm (3/4") outlet spout

Weight: 1.3kg

Power supply: 2 x AAA

INTRODUCTION:

1.1 Technical Data

1.1.1 The liquids compatible with auto shut off digital nozzle must be low viscosity.

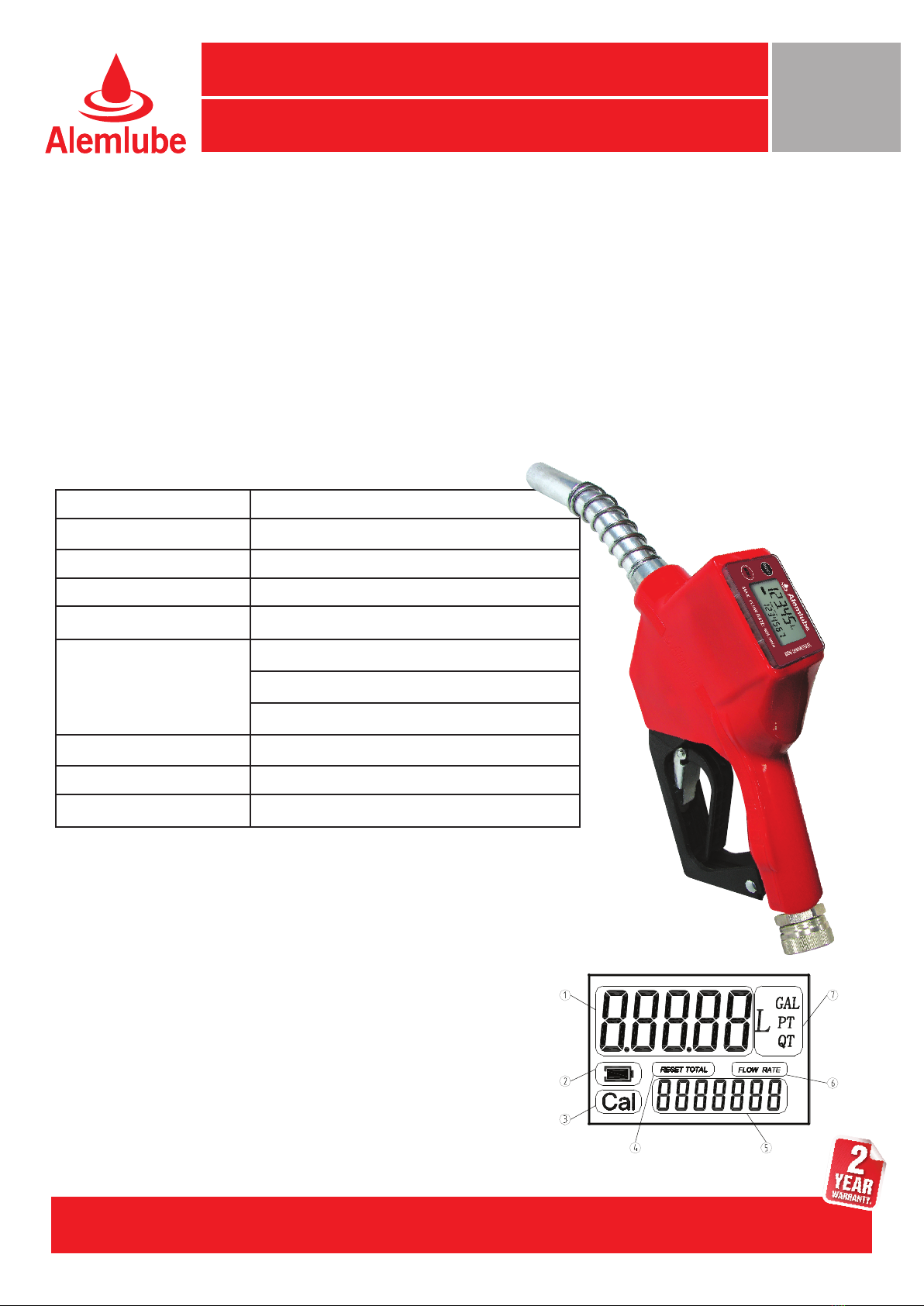

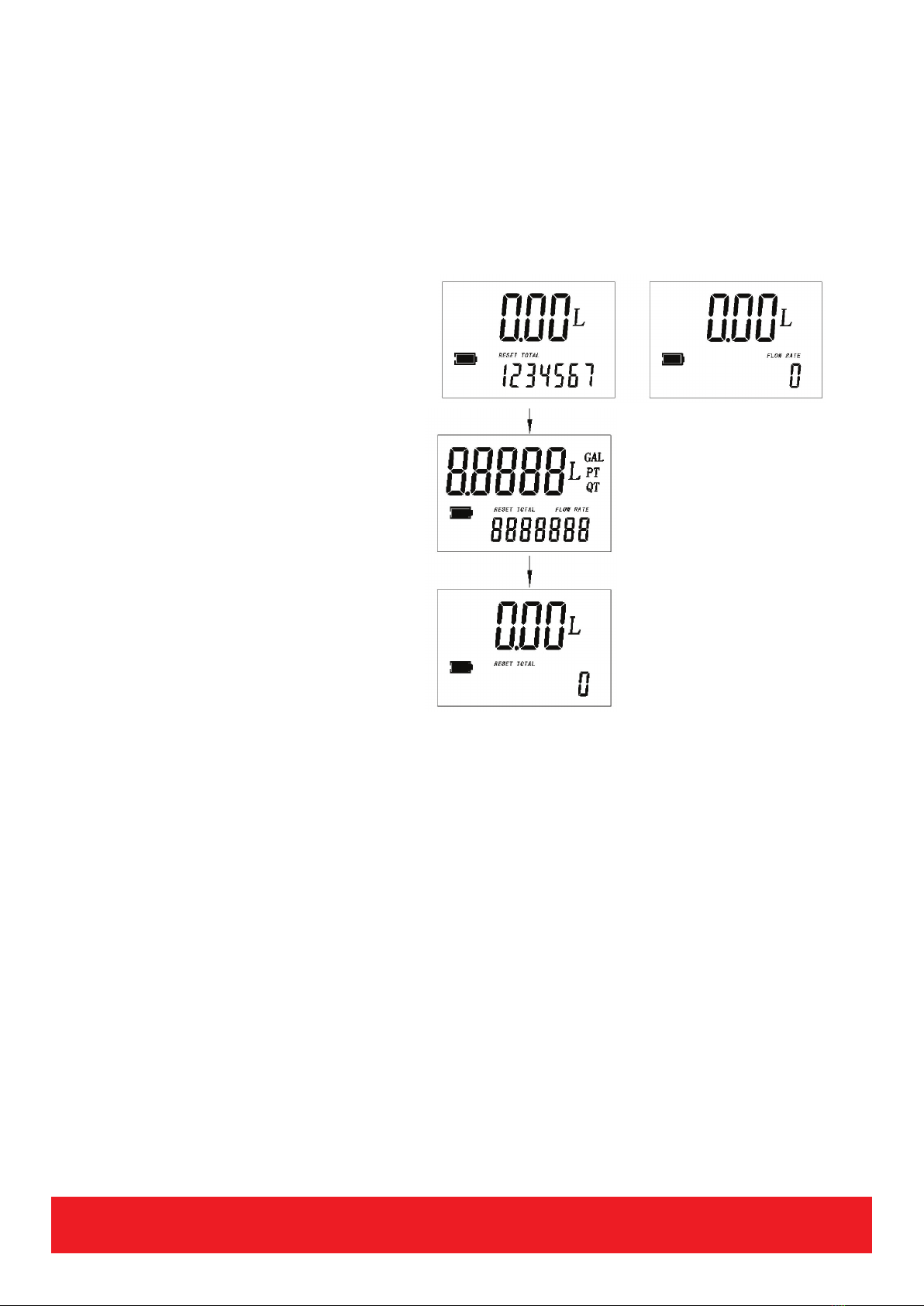

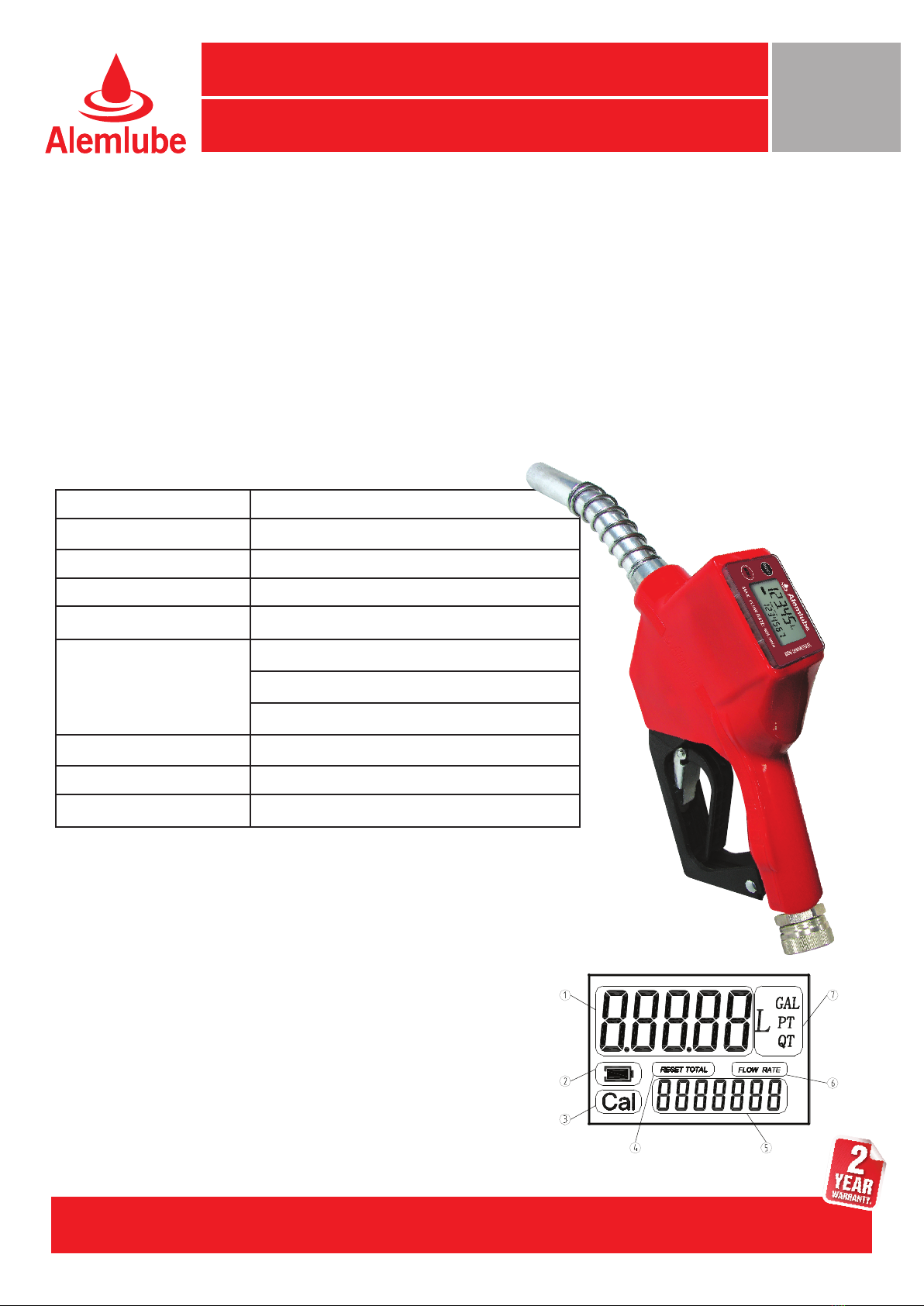

1.2 LCD Display

The “LCD” of the meter features two numerical Registers and various indications

displayed to the user only when the applicable function so requires

KEY

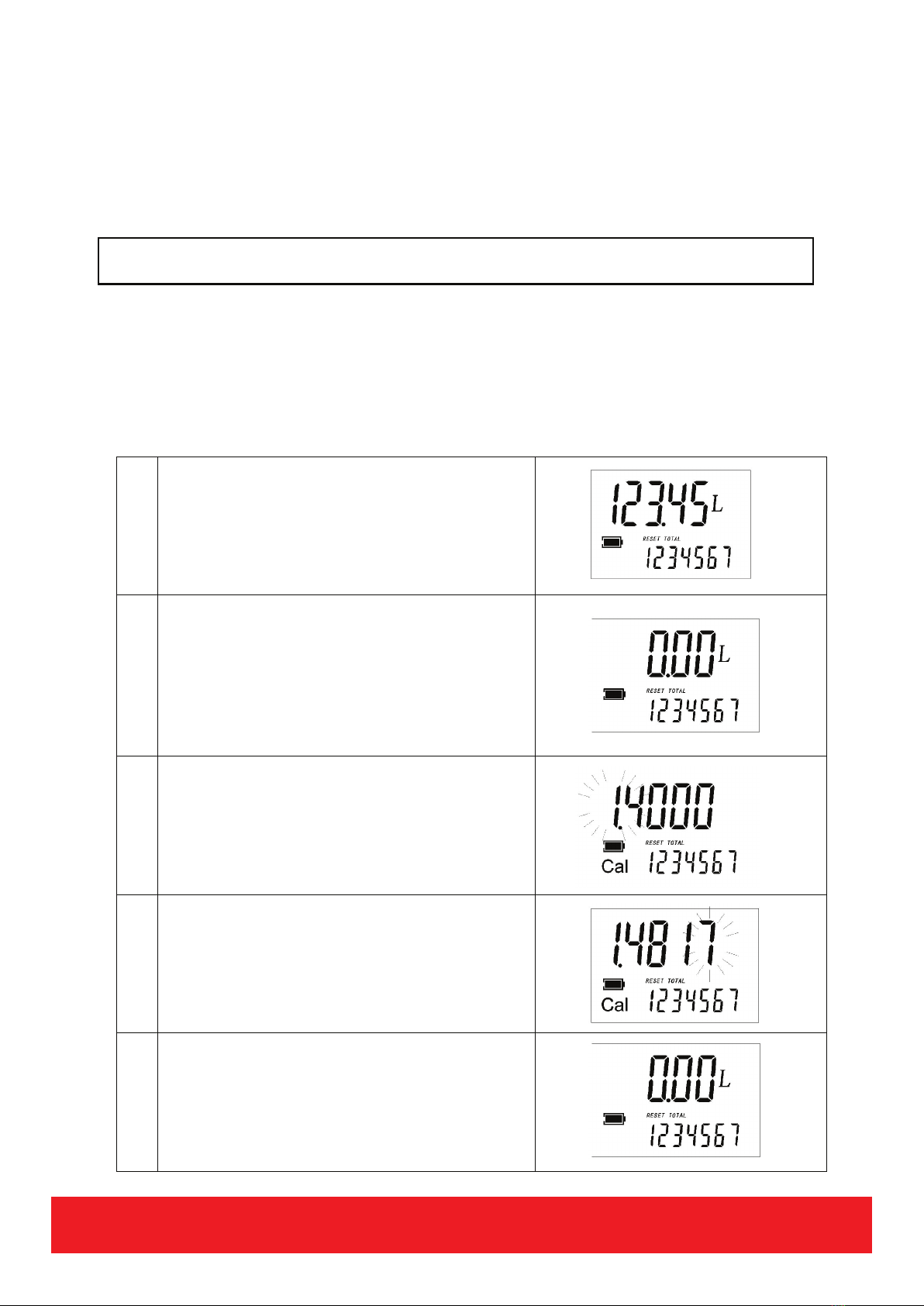

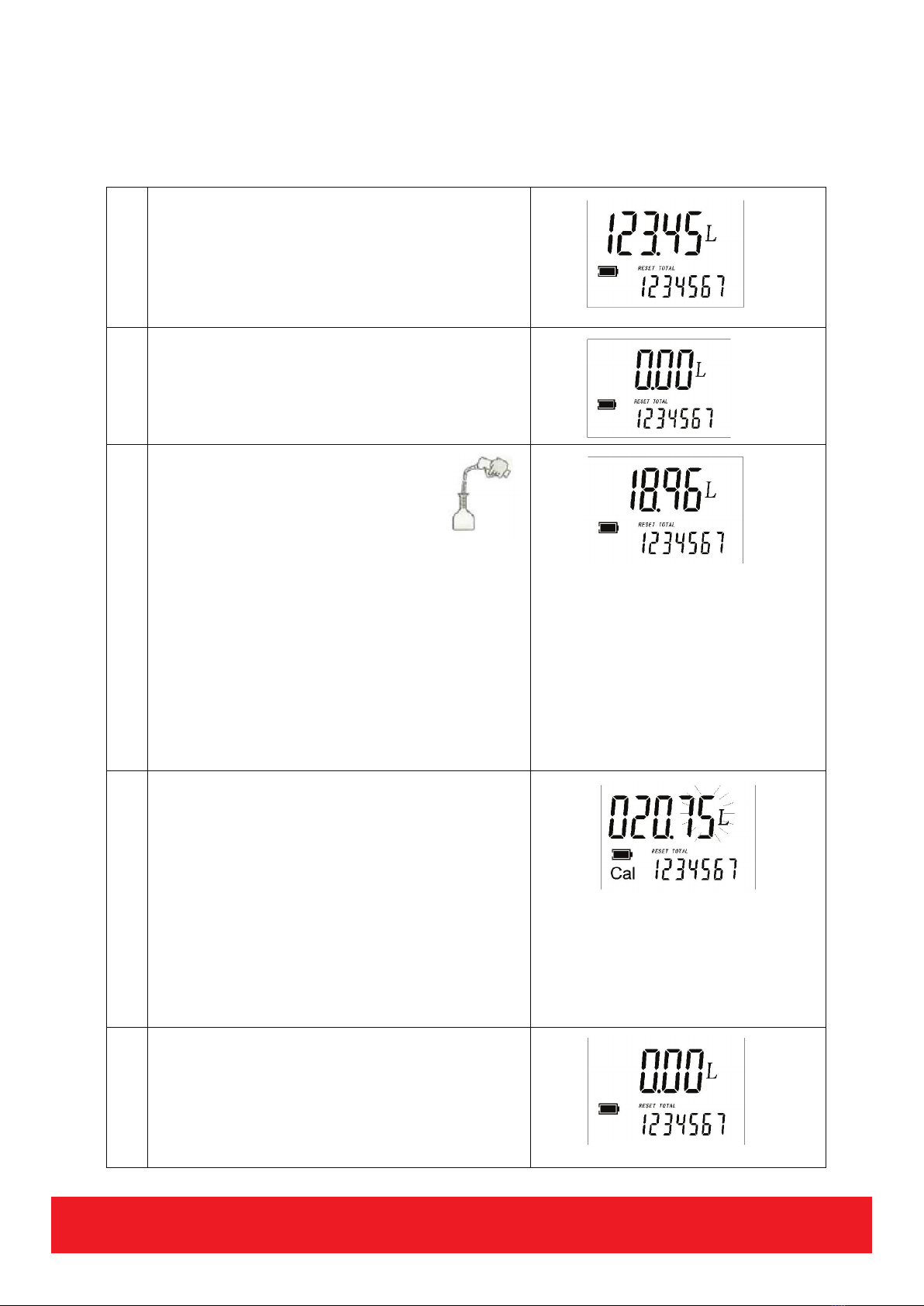

1. Partial register (5 figures with moving comma from 0.1 to 99999)

Indicating the volume dispensed since the reset button was last pressed

2. Indication of battery charge

3. Indication of calibration mode

4. Indication of resetting present total to Zero

5. Total register

6. Indication of flow rate mode

7. Indication of unit of measurement of partial: L= Litres

Description

The 51037M auto shut off nozzle uniquely designed with a built in digital meter is suitable for dispensing diesel fuel,

petrol, kerosene and will automatically shut off when a tank is full. This innovative combination of nozzle and meter saves

simplifies traditional separate nozzle and meter thinking and saves installation and usage time.

The digital meter is powered by 2 x AAA batteries, displays a 5-digit resettable total and a 7-digit (non resettable)

cumulative total function, and is accurate to ±1%. The LCD display can indicate several modes by pressing the menu

button including level of battery charge, flow rate, calibration and units of dispensed fuel (litres, gallons, pints or quarts).

And for peace of mind, spare parts for both nozzle and meter are readily available.

Flow rates of up to 60 L/min are achievable within operating temperatures of -10ºC to 60ºC with an operating pressure of

7 to 50psi (0.5-3.5 bar).

The 51037M comes complete with a 1” BSP(f) swivel and the outlet spout is 19mm (3/4”) in diameter.

NSW

TEL: (02) 9939 0711

FAX: (02) 9939 0411

QLD/PNG

TEL: (07) 3204 9166

FAX: (07) 3204 1224

VIC/TAS

TEL: (03) 8787 8288

FAX: (03) 8787 8266

WA

TEL: (08) 9302 4199

FAX: (08) 9303 2095

SA/NT

TEL: (08) 8241 7111

FAX: (08) 8241 7011

NZ

TEL: (09) 447 1007

FAX: (09) 447 1008

51037M Auto Shut Off Nozzle with Digital Meter 51037M

OWNER’S TECHNICAL MANUAL

Specifications

1.3 USER BUTTONS

1.4 BATTERY REPLACEMENT

2. INSTALLATION