Instruction Manual, Gunclean Toftejorg TZ-750 Fixed & Portable Page 1

Standard machines and machines delivered with ATEX certification

in accordance with Directive 94/9/EC

IM-TE91A400-EN7

Contents

Contents...................................................................................................................................1

Introduction...............................................................................................................................3

Intended Use............................................................................................................................4

Patents and trademarks............................................................................................................4

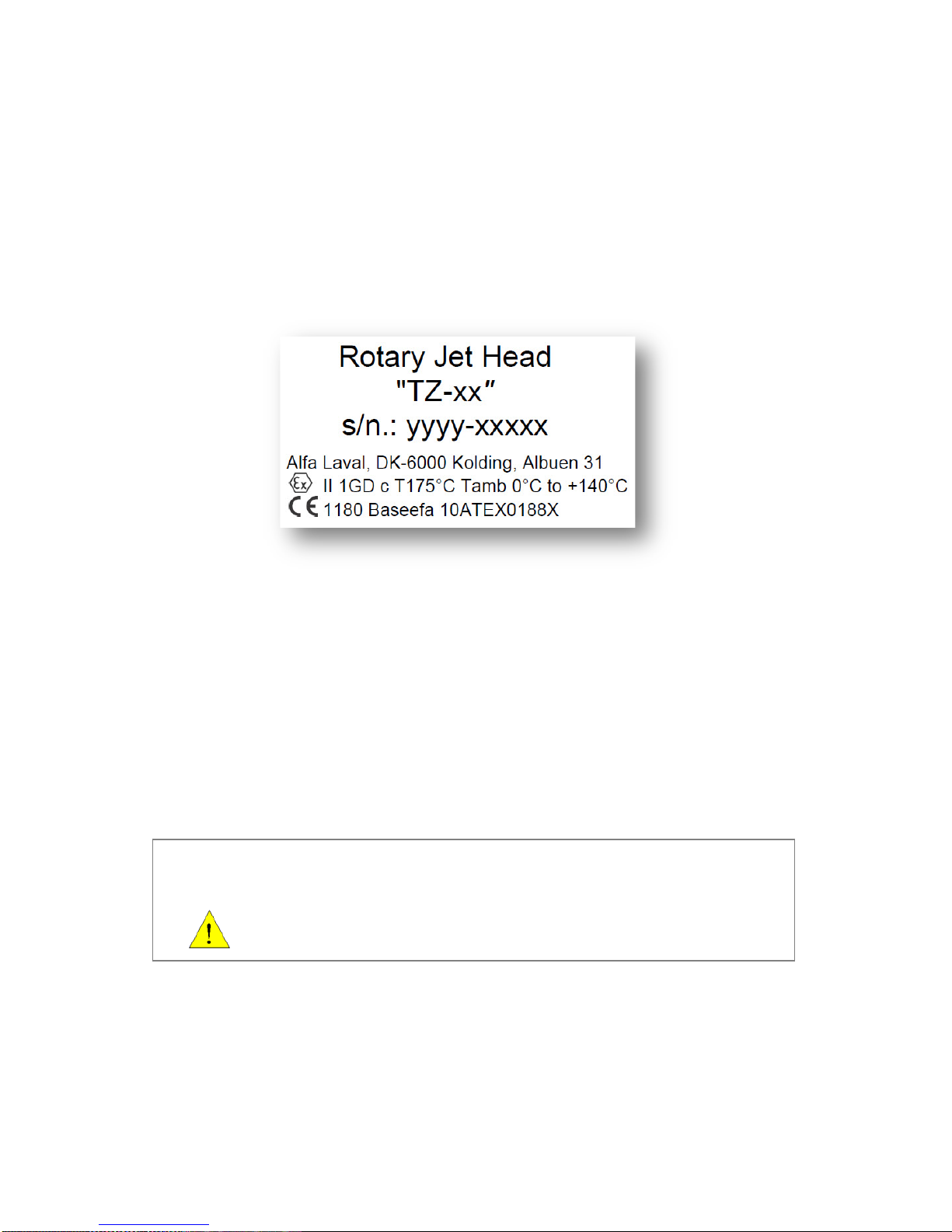

ATEX Marking...........................................................................................................................5

General Description ..................................................................................................................6

Functioning................................................................................................................................................6

Standard Configurations............................................................................................................................7

Options ......................................................................................................................................................7

Available add-ons......................................................................................................................................7

Technical Data..........................................................................................................................8

Gunclean Toftejorg TZ-750 Fixed..............................................................................................................8

Gunclean Toftejorg TZ-750 Portable..........................................................................................................9

Flow rate..................................................................................................................................................10

Throw length............................................................................................................................................11

Cleaning Time, f. Complete Pattern (= 4 cycles)......................................................................................12

Installation and Normal Operation ...........................................................................................13

General Safety and Installation Instructions.............................................................................................13

Normal Operation.....................................................................................................................................15

Special Conditions for Safe Use in accordance with the ATEX Certification, Directive 94/9/EC..............16

Maintenance and repair...........................................................................................................17

Service and Repair of ATEX Approved Machines....................................................................................17

Maintenance and repair...........................................................................................................18

Preventive Maintenance Guidelines and Service Kits..............................................................................18

Maintenance intervals and Service Kits selection....................................................................................18

Top Assembly..........................................................................................................................................20

Bottom Assembly.....................................................................................................................................22

Hub Subassembly....................................................................................................................................24

Stem Subassembly..................................................................................................................................26

Gear Subassembly..................................................................................................................................28

Replacement of Collar Bushes................................................................................................................30

Replacement of Ball races.......................................................................................................................32

Replacement of Main Collar.....................................................................................................................34

Tools ......................................................................................................................................36

Sketch of tool for replacement of Main collar...........................................................................................37

Trouble Shooting Guide..........................................................................................................38

Gunclean Toftejorg TZ-750 Fixed............................................................................................40

Reference List of Parts............................................................................................................................40

Cross Sectional Drawing..........................................................................................................................41

Gunclean Toftejorg TZ-750 Portable.......................................................................................42

Reference List of Parts............................................................................................................................42

Cross Sectional Drawing..........................................................................................................................43