Table of contents

The information herein is correct at the time of issue but may be subject to change without prior notice

1. EC Declaration of Conformity ....................................................................... 4

2. Safety .................................................................................................... 5

2.1. Important information ............................................................................. 5

2.2. Warning signs ..................................................................................... 5

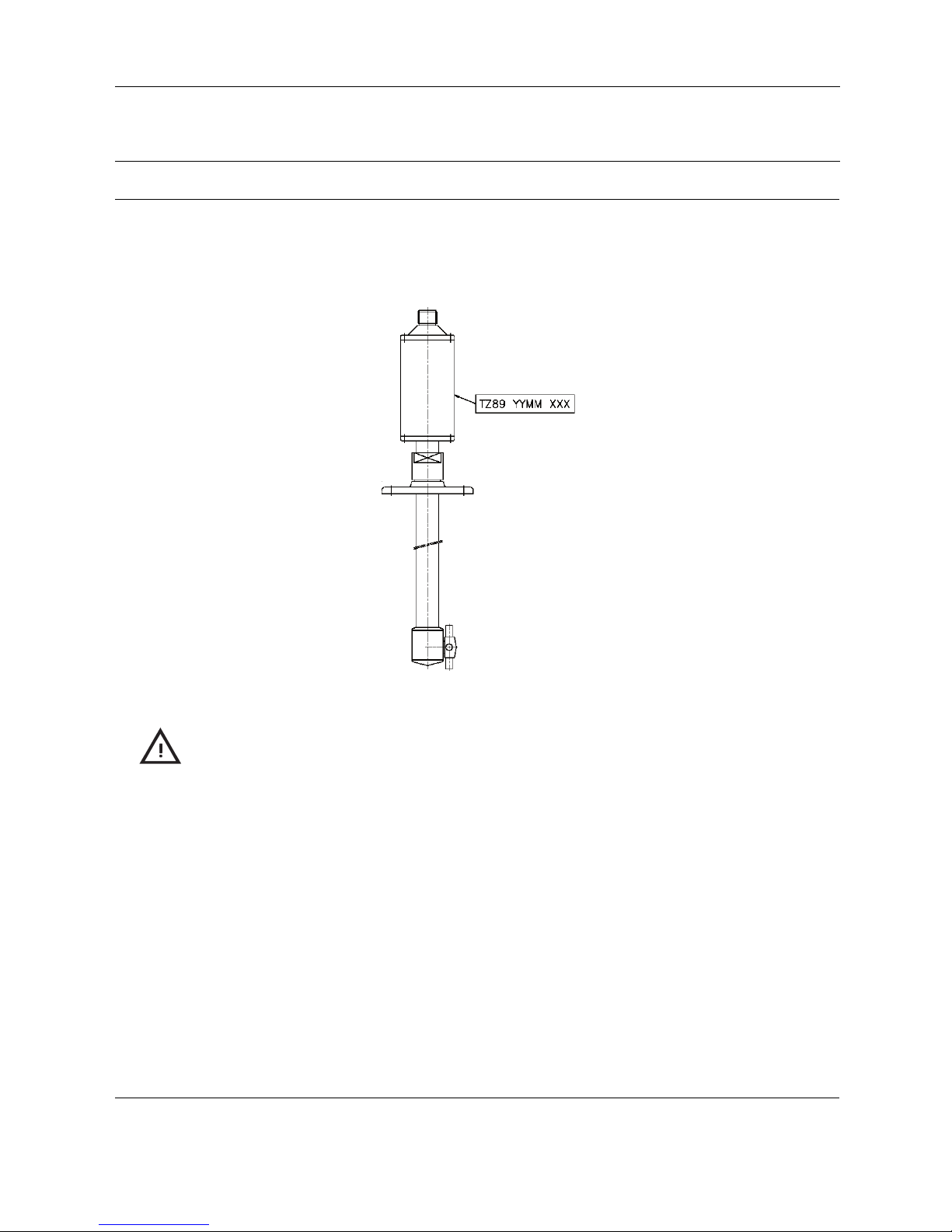

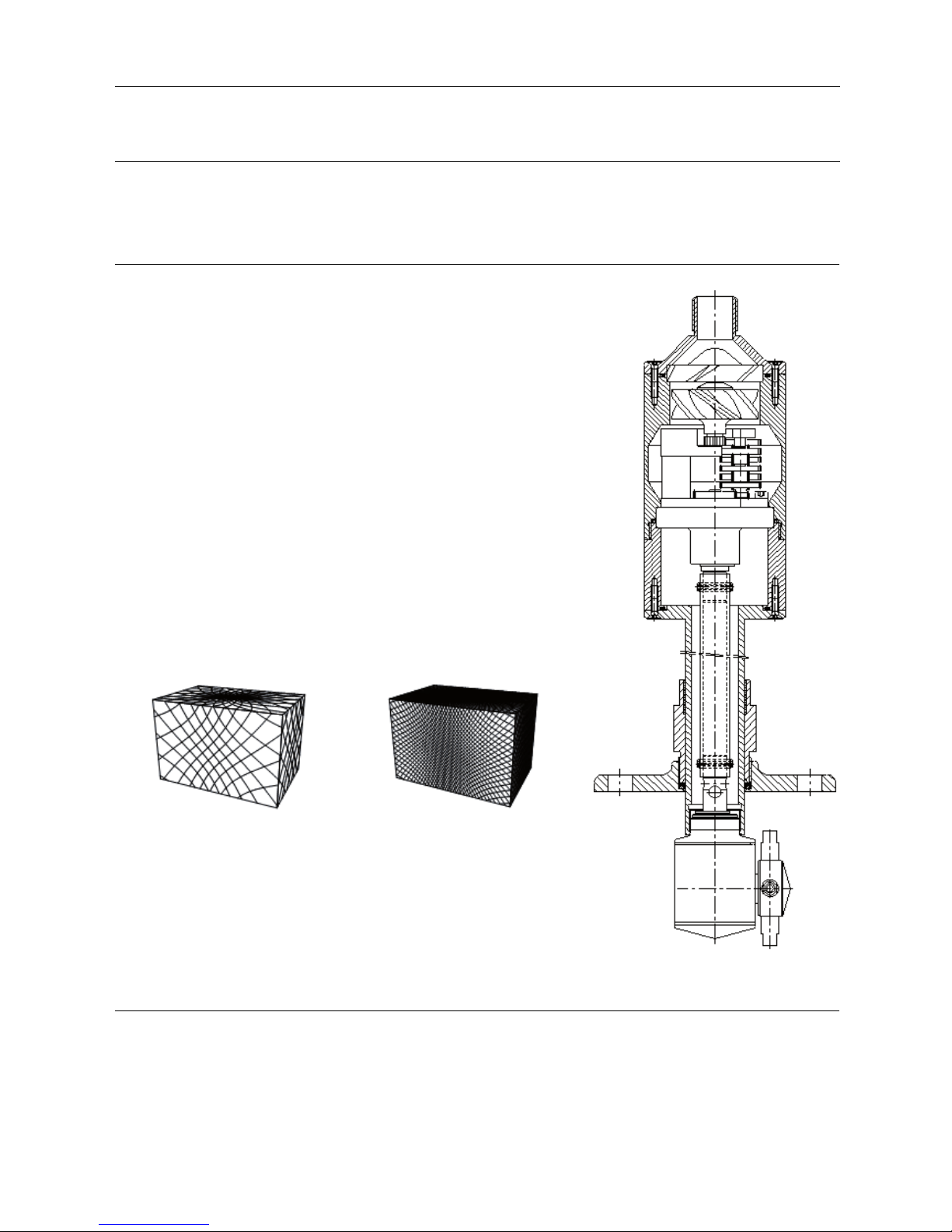

3. Introduction ............................................................................................ 6

3.1. Introduction ........................................................................................ 6

3.2. Intended Use ...................................................................................... 7

3.3. Patents and Trademarks ......................................................................... 7

3.4. Quality System .................................................................................... 7

4. Installation .............................................................................................. 8

4.1. Functioning ........................................................................................ 8

4.2. General Safety and Installation Instructions .................................................... 9

5. Operation ............................................................................................... 10

5.1. Normal operation ................................................................................. 10

6. Maintenance and Repair ............................................................................. 11

6.1. Preventive Maintenance .......................................................................... 11

6.2. Main Assembly .................................................................................... 12

6.3. Gear Unit .......................................................................................... 14

6.4. Cleaner Head ...................................................................................... 16

7. Trouble Shooting Guide .............................................................................. 18

8. Technical Data ......................................................................................... 19

9. Product Programme .................................................................................. 23

9.1. Standard Configurations ......................................................................... 23

10. Parts Lists, Service Kits and Tools ................................................................. 24

10.1.Reference list of parts, TZ-89 .................................................................... 24

10.2.Reference list of parts, TZ-89LF ................................................................. 25

10.3.Exploded view drawing, TZ-89 & TZ-89LF ..................................................... 26

10.4.Spare part kits, service kits and Tools .......................................................... 27

11. General information ................................................................................... 29

11.1.Service and Repair ............................................................................... 29

11.2.How to Order Spare Parts ....................................................................... 29

11.3.How to contact Alfa Laval Tank Equipment .................................................... 29

3