15

BASIC INFORMATION CONCERNING THE HANDLING OF MAGNETIC

LIFTING GEAR IN PARTICULAR TML / TMH

The magnetic surface is located on the underside of the lifting magnet incorporating dierent magnetic poles

which generate the magnetic holding force through magnetic flux when activated. The maximum holding

force that can be achieved depends on dierent factors which are explained below:

Material thickness

The magnetic flux of the lifting magnet requires a minimum material thickness to flow completely into the

load. Below this minimum thickness of material, the maximum holding force is reduced subject to material

thickness. Conventional switchable permanent magnets have a deeply penetrating magnetic field similar to

tree tap roots, and require a large material thickness to achieve maximum holding force. The compact magnetic

field of TML and TMH magnets is similar to a shallow root and achieves maximum holding force even when

used on thin materials (see performance data in table 2).

Material

Every material reacts in a dierent way to penetration of the magnetic field lines. The load-bearing capacity

of the lifting magnets is determined using an S235 material. Steels with high carbon content or whose

structure has been changed by heat treatment have a low holding force. Foamed or porous cast components

also have a lower holding force, so that the given load-bearing capacity of the lifting magnet can be

downgraded on the basis of the following table 1.

Table 1

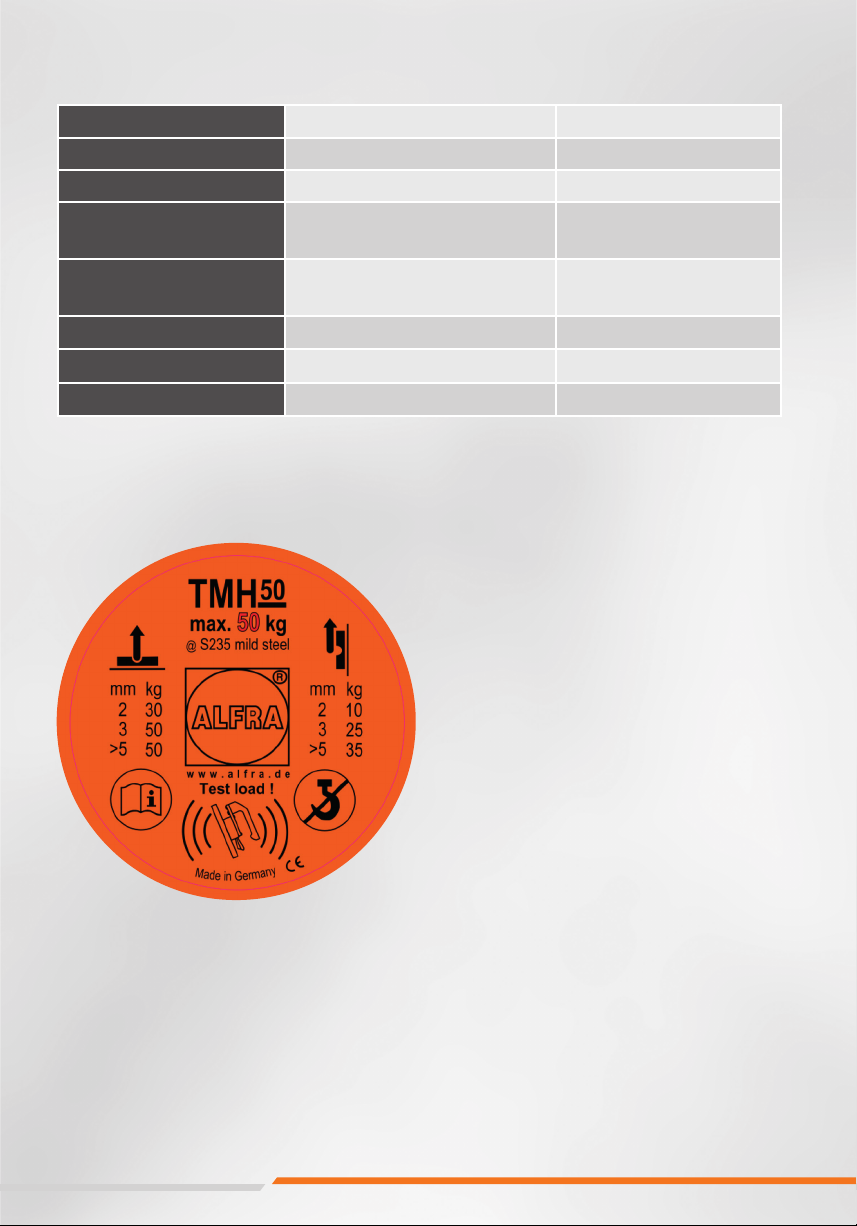

Surfacequality

The maximum holding force of a lifting magnet can be achieved in case of a closed magnetic circuit in which

the magnetic field lines can connect up freely between the poles, thus creating a high magnetic flux. In contrast

to iron, for example, air has very high resistance to magnetic flux. If an air gap is formed between the lifting

magnet and the work piece, the holding force will be reduced. In the same way, paint, rust, scale, surface

coatings, grease or similar substances all constitute a space(i.e. an air gap), between work piece and lifting

magnet. Furthermore, an increasein surface roughness or unevenness has an adverse eect on the magnetic

holding force. Reference values for your TMH 50 can be found in table 2.

Load dimensions

When working with large workpieces such as girders or plates, the load canpartly become deformed during

the lift. A large steel plate would bend downwards at the outer edges and create a curved surface which no

longer has full contact with the bottom of the magnet. The resulting air gap reduces the maximum load-

bearing capacity of the lifting magnet. In contrast to this, nor should objects be hollow or smaller than the

magnetic surface, as otherwise the entire power of the lifting magnet will not be used.

Load alignment

During load transport care must be taken that the lifting magnet is always at the centre of gravity of the work piece

and that load, or lifting magnet respectively, is always aligned horizontally. In this case, the magnetic force of

the lifter acts with its full pull-o strength at right anglesin relation to the surface and the maximum rated load-

bearing capacity is achieved through the 1:3 standard safety factor. If the position of work piece and lifting magnet

changes from horizontal to vertical, the lifting magnet is operated in shear mode and the workpiece can slip

away to the side. In shear mode, the load-bearing capacity decreases dependent upon the coecient of friction

between the two materials.

Temperature

The high-power permanent magnets installed in the lifting magnet irreversibly lose their magnetic properties

from a temperature of more than 80°C, so that the full load-bearing capacity is never reached again even after

the magnet has cooled down. Please note the specifications on your product and in the operating manual.

Material Magneticforce in %

Non-alloyed steel (0.1-0.3% C content) 100

Non-alloyed steel (0.3-0.5% C content) 90-95

Cast steel 90

Grey castiron 45

Nickel 11

Stainlesssteel, aluminium, brass 0