8800793

Section 2 Introduction

© Copyright, Alliance Laundry Systems LLC –DO NOT COPY or TRANSMIT

While water fills the inner basket, a column of air is

trapped in a pressure bulb and hose. The air pressure

continues to increase as the inner basket fills with

water until it is great enough to activate the pressure

switch. Then the pressure switch causes the wash fill

to stop and starts the reversing rotational washing

cycle.

The reversing rotational cycle tumbles the clothing in a

clockwise direction for a period of 20 seconds, pauses

for 9 seconds and then tumbles the clothing in a

counterclockwise direction for 10 seconds. This action

continues until the completion of the wash cycle

selected on the timer.

Upon completion of the wash cycle, the machine goes

into a rinse cycle. The rinse cycle consists of a spin

mode that removes the majority of the detergent water

from the clothing and also activates the electric water

pump which removes the wash water. Fresh

temperature selected water is brought into the inner

basket via the mixing valve, the pressure switch shuts

off the water and then a rinse cycle starts. The rinse

cycle consists of a tumble reversing action similar to

the washing cycle for a pre-determined amount of

time, a spin mode, and includes water being pumped

out and fresh water being brought into the washer.

Several of these rinse cycles will take place, based

upon the operator timer wash type selection and the

optional activation of the “Extra Rinse”switch selector

on the control panel.

After all the rinse cycles have been completed, the

washer goes into a 1059 rpm final spin cycle for 90

seconds to extract as much water as possible from the

clothing, preparing them for the dryer. When this fast

spin cycle is completed, the washer goes into a fluff

tumble mode similar to agitate, only without water.

Operation stops and the loading door interlock is

deactivated allowing operator entry into the washer.

Technical

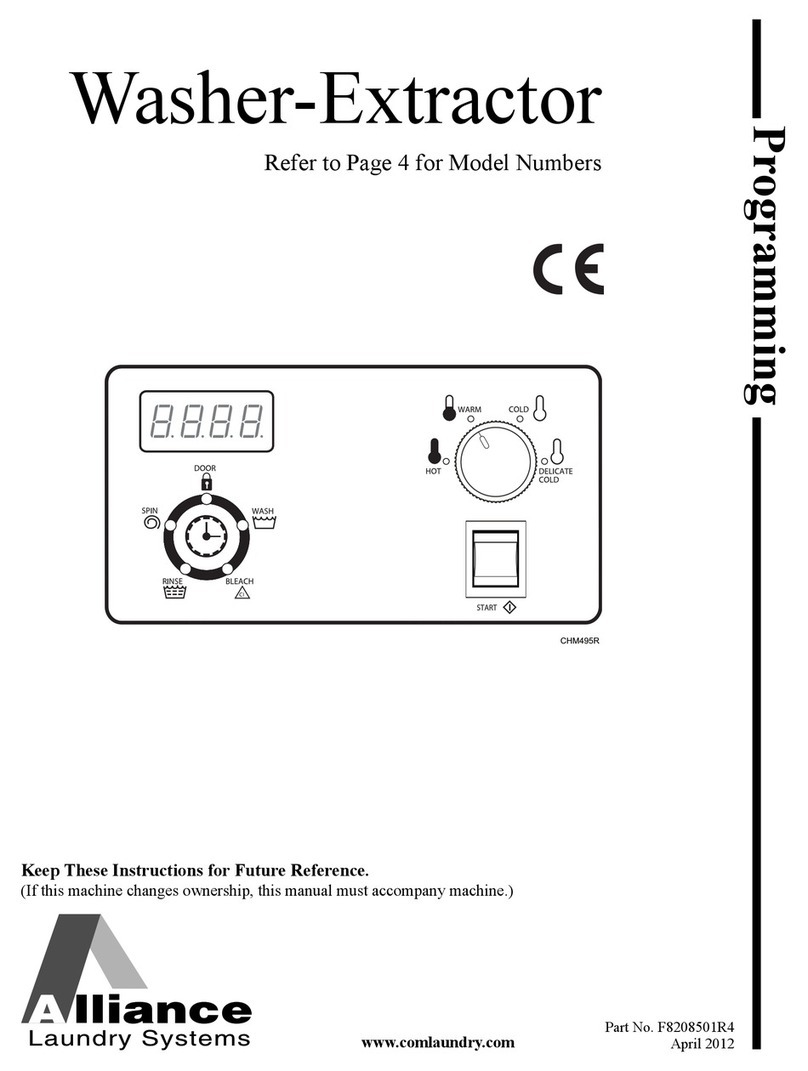

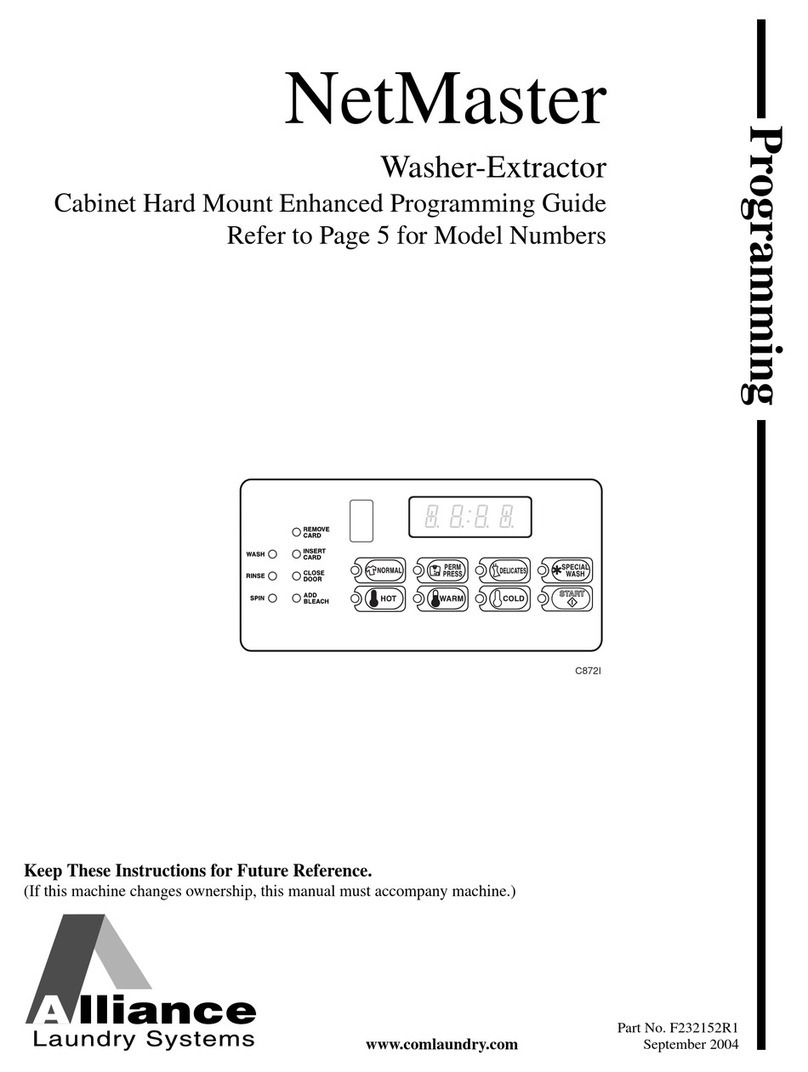

The basic operational controls of this washer consist of

the motor control logic board, timer, pressure switch,

temperature switch, D.C. motor and electric pump.

The principle of operation remains the same as other

washing machines. The door locks and starts the timer.

The timer starts the machine process by first having

the electronic control activate the dual water inlet

mixing valve which starts to fill the washer via the

dispenser mixing valve. The water temperature is

determined by the operator-selected temperature

switch position, which selects the hot, cold or both

mixing valves. The second step is adding the detergent

and other washing ingredients. This process continues

until the air pressure, via the pressure bulb and hose,

activates the pressure switch, which overrides the

timer fill command.

The timer continues its rotational cycle, which then

sends the command to the motor control board to start

the timer rotator. The tumble rotating action is a

specific wash cycle rotation, pause and then reverse

rotation. This process continues for an operator’s

selected period of time.

The next command mode the timer signals to the

motor control board is to start the rinse cycle. This

cycle signals the electric pump to turn on and direct

the wash water out of the washer. The motor control

board then commands the motor to go into a faster spin

cycle in an attempt to remove a reasonable amount of

water out of the clothing. The spin cycle stops and

then adds fresh rinse water into the washer via the inlet

mixing valve and dispenser hose. After the pressure

switch shuts off the water inlet mixing valve, the

motor control board commands the motor to start the

normal wash rotational, pause, reverse direction

process for a timer-controlled amount of time. This

rinse cycle is completed twice unless the extra rinse

switch has been selected by the operator. Another rinse

cycle takes place each time the extra rinse switch is

selected.

The next portion of the wash cycle is the spin cycle. In

this cycle the control board turns the electric pump on

to remove the rinse water from the tub. The washer

will spin at a distribution speed of 90 rpm until the

pressure switch is satisfied as empty. The washer then

goes to a 500 rpm spin for 30 seconds and returns to

the 90 rpm distribution speed for another 30 seconds.

This allows the motor control board to “sense”the out-

of-balance condition of the load. This sequence is

repeated any time the washer attempts to go to a spin

speed. At this time the washer then goes into a final

spin mode of 650 rpm for approximately 5 minutes

and ramps up to 1059* rpm for the remaining 90

seconds.

*(For Regular and Rinse and Spin cycles only).