ITA ENG FRA ESP DEU POR

6-1622372 rev.5 04/02/2016

Compatible from firmware version AS2405 - running velocity is modificable

Pag 9 di 10

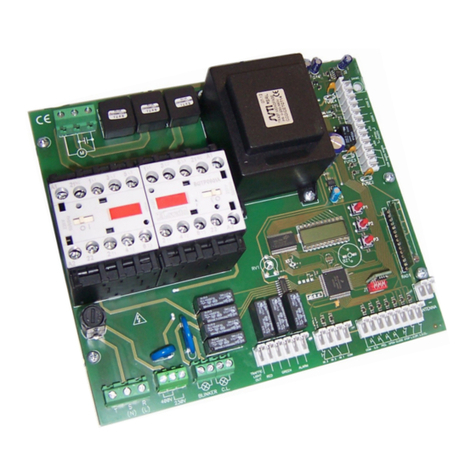

18. State of alarm of the control unit

If the flashing light blinks fastly or remains fixed, it means that the control unit is in state of alarm. Any command is ignored until the resolution of the

problem.

Condominium active + automatic reclosure

deactivated

Enable the automatic re-closure by turning the

trimmer in anti clockwise sense or deactivate the

condominium function (dip 4 off).

Probable cause SolutionType of problem

Fast blinking of the flashing light

Flashing light still and lit

Intervention of thermical protection of the

control unit. Too high stream absorption. The

value must not be higher than 7A for more

than 3 sec.

Each command is ignored for 20 seconds. Check

the motor status and their absorption.

In case it would be necessary to modify the decoding type (from rolling code to fix code or vice versa), or cancel all the learned transmitters,

proceed as follows:

1. Cut off the power supply to the system

2. Press the blue key if you want to select the fix code decoding or press the red if you want to select the rolling code decoding

3. Keep them pressed while you give again tension

4. Keep them again pressed until the flashing light lights on 3 times

5. At this point release the key and wait until the flashing light lights off. The selection of the decoding and the total deletion of the memory

have not been carried out.

17. Selection of the decoding type and total deletion of the memory

15. Modality of photocells intervention

The modality of photocells intervention is different:

•

The internal photocells unlock the movement until the obstacle is removed, so they involve the complete opening of the gate.

•

The external photocells do not intervene in opening, while they immediately invert the motion until the complete re opening in case of ob-

stacle in closing.

16. Control unit operation mode

The modality of intervention of the current sensor is only one. In case of intervention of the sensor in opening, the gate carry out a short inversion.

In case of intervention in closing , the immediate inversion is got with the total re opening of the gate.

In case the condominium function is selected, the happening of a sense in closing involves a short inversion in opening with a successive stop of

the motion until the reception of an order.

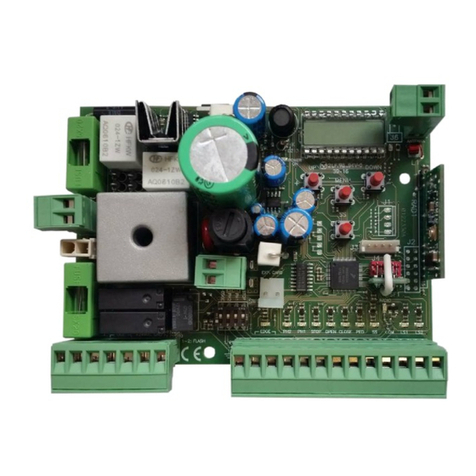

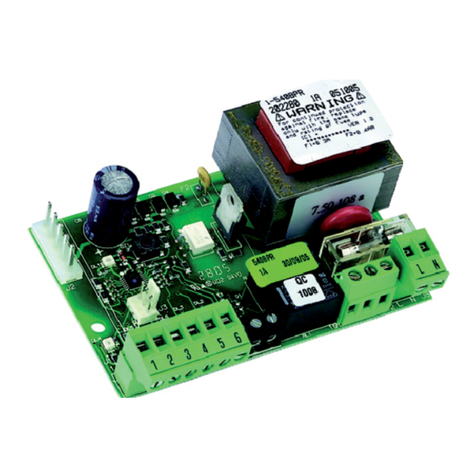

A B

C

D

C

D

E

E

WARNING: cutting the little bridge “J1” the inversion movement

zone is cancelled (zone “A”) and substituted with the setting of the

position reached as total closing/opening position (zone “C”).

A= Intervention zone of the amperometric sensor

with movement inversion

B= Normal speed run zone

C= Intervention zone of the amperometric sensor

with movement stop and setting of the reached

position as total closing/opening position. In the

version with encoder this area is not present.

D= Low speed run zone

E= Mechanical stops at opening and closing

(Absolutely necessary )

16.1 Forced opening of the wings

In case of wing’s overlap and consequent block of the automation, it is necessary to force the opening (re – synchronization). To do this, proceed

as follows:

1. Press the first key of the transmitter for a time superior than 8 seconds.

2. The control unit signals the imminent re – synchronization with a pre – flashing. DO NOT release the key.

3. The two wings start to open contemporarily. DO NOT release the key.

4. When the wings have reached an opening sufficient to not come into collision, release the key. The wings stop.

5. Press again the key of the transmitter. The wing 1 starts to close itself and once closed, the wing 2 also closes .

6. Once closed the gate, the operation of re – synchronization is ended and the wing is ready to work regularly.

NOTE: During the phase of re – synchronization, it is possible to close only 1 wing at a time. The functioning come back to be regular only when

both wings are correctly closed.

WARNING: during the operation of re – synchronization the intervention of the anti – squashing security is interpreted as identification

of the close position. In order to avoid the voluntary intervention, the sensitivity of the same results remarkably reduced respect to the

conditions of normal functioning.