10

FIGURE 25

39.Assembletheowcontrolgauge(5)tothehopper

braceusingthe1/4"x3/4"carriagebolt(G),anylon

washer(R)andtheplasticknob(X).Seegure25.

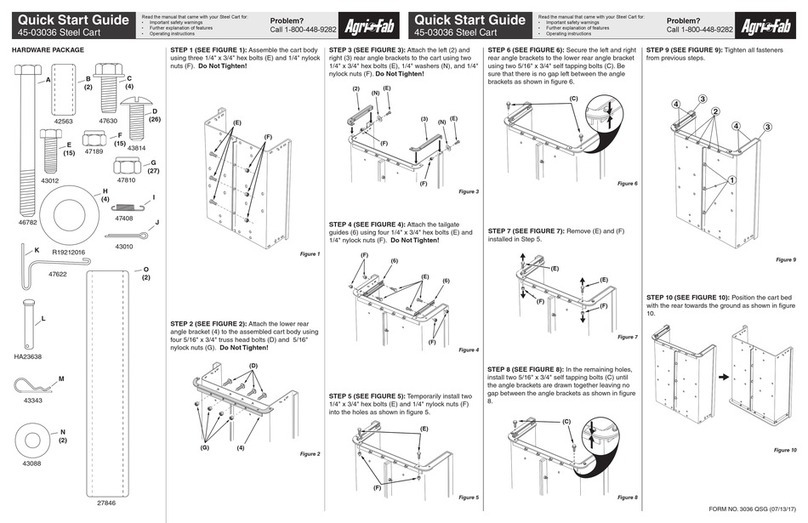

34.Insertatonguebrace(8)throughtheslotintheend

plate.Fastenthefrontholeofthetonguebracetothe

endplateusinga1/4"x5/8"hexbolt(F)and1/4"

nylocknut(J).Fortherearholeusea1/4"x3/4"hex

bolt(E),1/4"atwasher(Q),and1/4"nylocknut(J),

withtheboltandwasherassembledfrominsidethe

hopper.Do not tighten yet. Seegure23.

35.Fastentheotherendofthetonguebrace(8)tothe

sideofthetongueusingtwo1/4"x5/8"hexbolts(F)

and1/4"nylocknuts(J).Do not tighten yet.See

gure23.

36.Repeatsteps10and11forthesecondtonguebrace.

3 7. Tightenallboltsandnutsassembledsofar.

FIGURE 23

FIGURE 22

32.Attachthehopperbrace(4)tothehopperusingtwo

1/4"x5/8"hexbolts(F),one1/4"atwasher(Q),

andtwo1/4"nylocknuts(J).Do not tighten yet.See

gure22.

33.Placetheendofthehitchbracket(10)withtwoholes

downthroughtheslotinthetongue.Attachthehopper

bracetothetopofthetongueandthehitchbracketto

thebottomusingone3/8"x1"hexbolt(B)andone

3/8"nylocknut(L).Do not tighten yet.Seegure22.

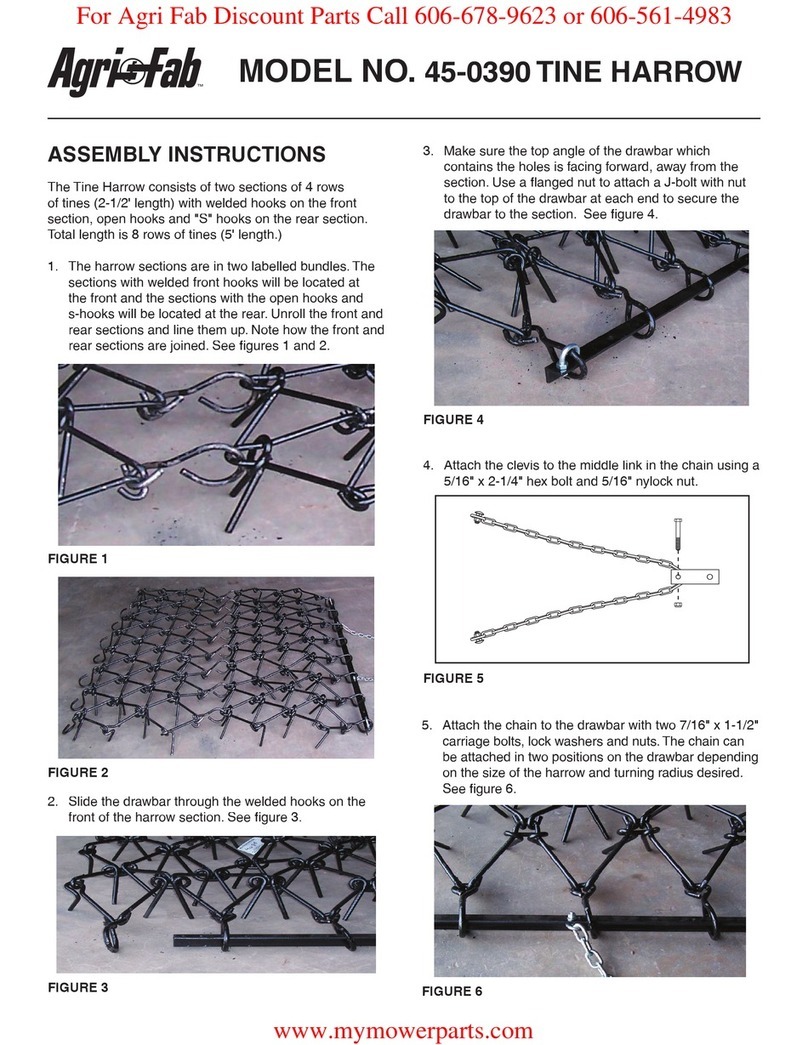

38.Assemblea1/2"x4"hexbolt(A),a1/2"washer(P),

awheel,a1/2"washer(P),anda1/2"jamnut(N).

Finger tighten only. Attachthewheelassemblyto

thetransporttubeusinga1/2"nylockhexjamnut(S).

Repeatfortheotherside.Seegure24.

FIGURE 24

A

P

P

N

S

L

F

B

Q

J

4

10

F

J

F

J

8

E

Q

J

X

R

G

5