ii

TABLE OF CONTENTS

1INTRODUCTION.....................................................................................................................................................1

1.1 Scope of the Manual ..................................................................................................................................... 1

1.2 Product Overview ......................................................................................................................................... 1

1.3 Part Numbers and List Options ..................................................................................................................... 1

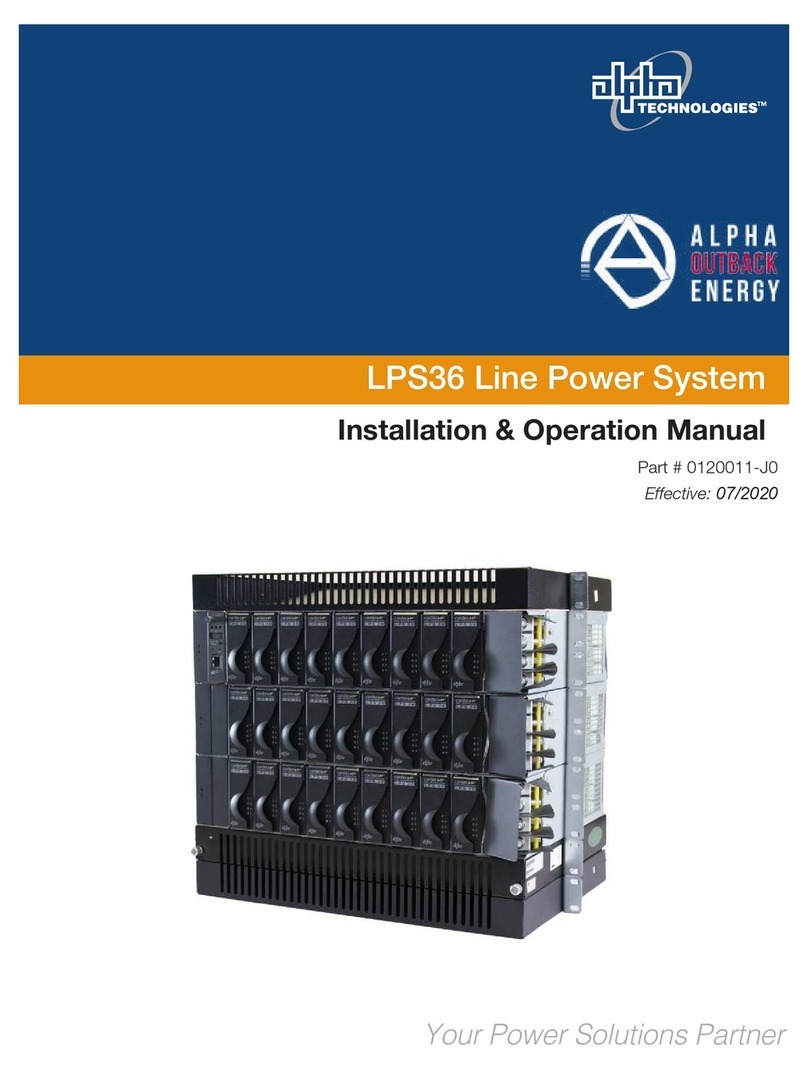

2CONVERTER MODULE FEATURES...............................................................................................................................2

2.1 Microcontroller ............................................................................................................................................. 2

2.2 Indicators ...................................................................................................................................................... 2

2.3 Test Points..................................................................................................................................................... 2

2.4 Lock ............................................................................................................................................................... 2

2.5 Handle ........................................................................................................................................................... 2

2.6 DC Inputs....................................................................................................................................................... 3

2.7 Input Low Voltage Lockout ........................................................................................................................... 3

2.8 Input Current Limit........................................................................................................................................ 3

2.9 DC Output ..................................................................................................................................................... 3

2.10 Output Power................................................................................................................................................ 3

2.11 Over Voltage Protection (OVP) ..................................................................................................................... 3

2.12 Output Current Limit..................................................................................................................................... 3

2.13 Regulation and Paralleling ............................................................................................................................ 3

2.14 Over Temperature Protection ...................................................................................................................... 4

2.15 Ventilation..................................................................................................................................................... 4

2.16 Paralleling Diode ........................................................................................................................................... 4

2.17 Reverse Polarity Operation........................................................................................................................... 4

3INSPECTION .........................................................................................................................................................5

3.1 Packing Materials.......................................................................................................................................... 5

3.2 Check for Damage......................................................................................................................................... 5

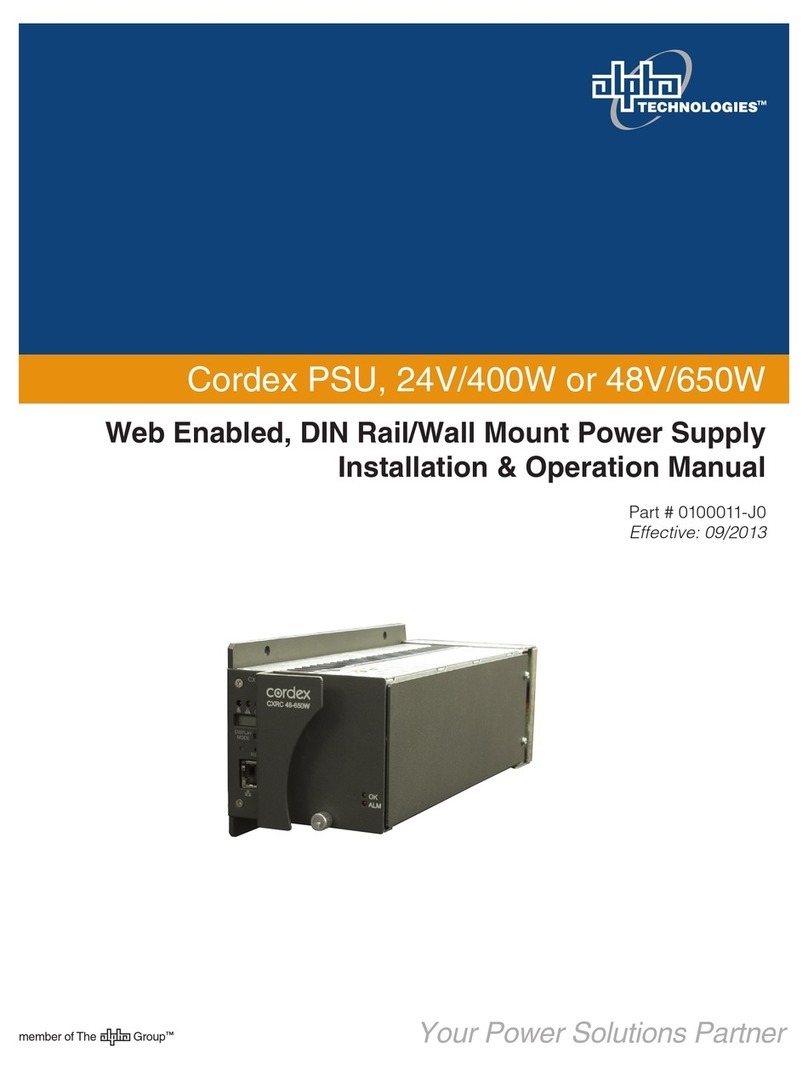

4INSTALLATION ......................................................................................................................................................6

4.1 Safety Precautions ........................................................................................................................................ 6

4.2 Tools Required .............................................................................................................................................. 6

4.3 Module Insertion/Removal........................................................................................................................... 6

5WIRING AND CONNECTIONS ....................................................................................................................................8

5.1 Safety Precautions ........................................................................................................................................ 8

5.2 Chassis Ground ............................................................................................................................................. 8

5.3 DC Input ........................................................................................................................................................ 8

5.4 DC Output Shelf Connection......................................................................................................................... 8

6INITIAL STARTUP ...................................................................................................................................................9