39400016-J0 Rev D

Table of Contents

1. Safety....................................................................................................................................6

1.1 Safety Symbols .......................................................................................................................... 6

1.2 General Warning and Cautions.................................................................................................. 6

1.3 Electrical Safety ......................................................................................................................... 7

1.4 Battery Safety ............................................................................................................................ 7

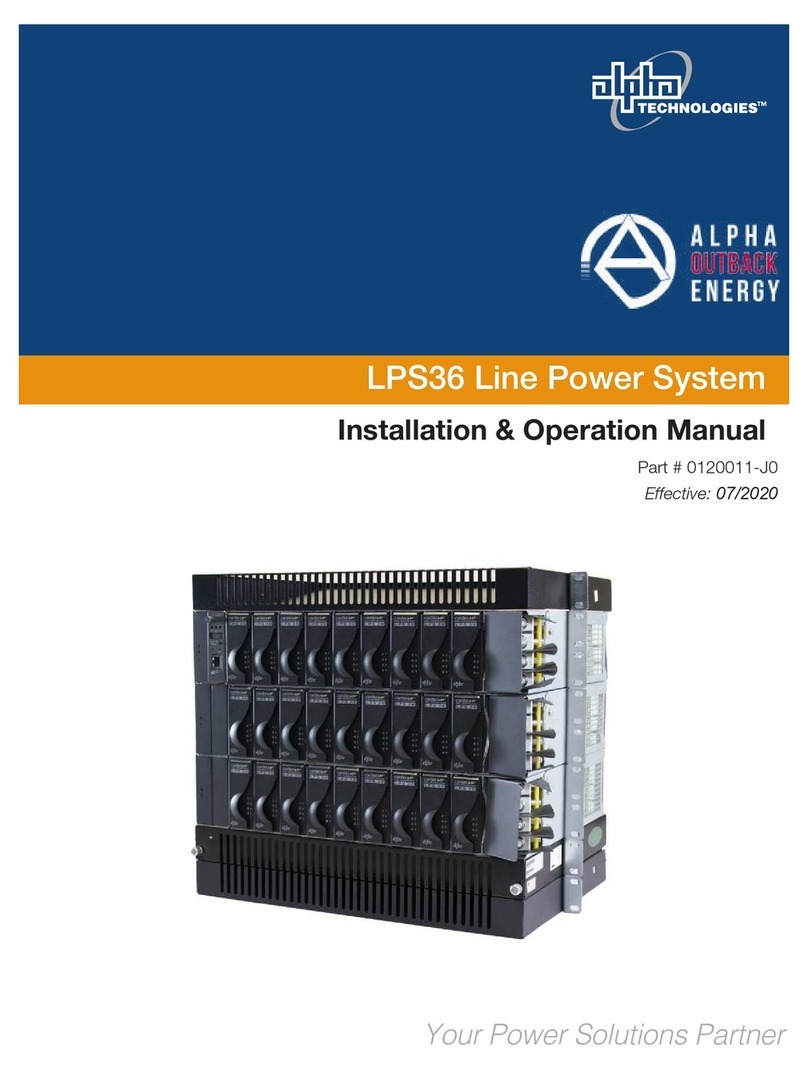

2. Introduction ...........................................................................................................................8

2.1 Scope of the Manual .................................................................................................................. 8

2.2 Product Overview....................................................................................................................... 8

2.3 System Congurations............................................................................................................... 9

3. Specications......................................................................................................................11

4. Features..............................................................................................................................12

4.1 Seismic Racks ......................................................................................................................... 12

4.2 Distribution Centers ................................................................................................................. 12

4.3 Front Panel with a CXC HP Controller..................................................................................... 14

4.4 L-ADIO ..................................................................................................................................... 15

4.5 2.4kW Rectier......................................................................................................................... 17

4.6 4.0kW Rectier......................................................................................................................... 17

4.7 LVD Override ........................................................................................................................... 18

4.8 Integrated Battery Trays........................................................................................................... 20

4.9 Battery Landing Busbar Kit ...................................................................................................... 20

5. Inspection............................................................................................................................21

5.1 Packing Materials..................................................................................................................... 21

5.2 Check for Damage ................................................................................................................... 21

5.3 General Receipt of Shipment................................................................................................... 21

6. Installation...........................................................................................................................22

6.1 Safety Precautions................................................................................................................... 22

6.2 Tools Required ......................................................................................................................... 22

6.3 Installation of External Batteries .............................................................................................. 22

6.4 Battery Maintenance Report .................................................................................................... 24