i

TABLE OF CONTENTS

1INTRODUCTION ............................................................................................................................................................. 1

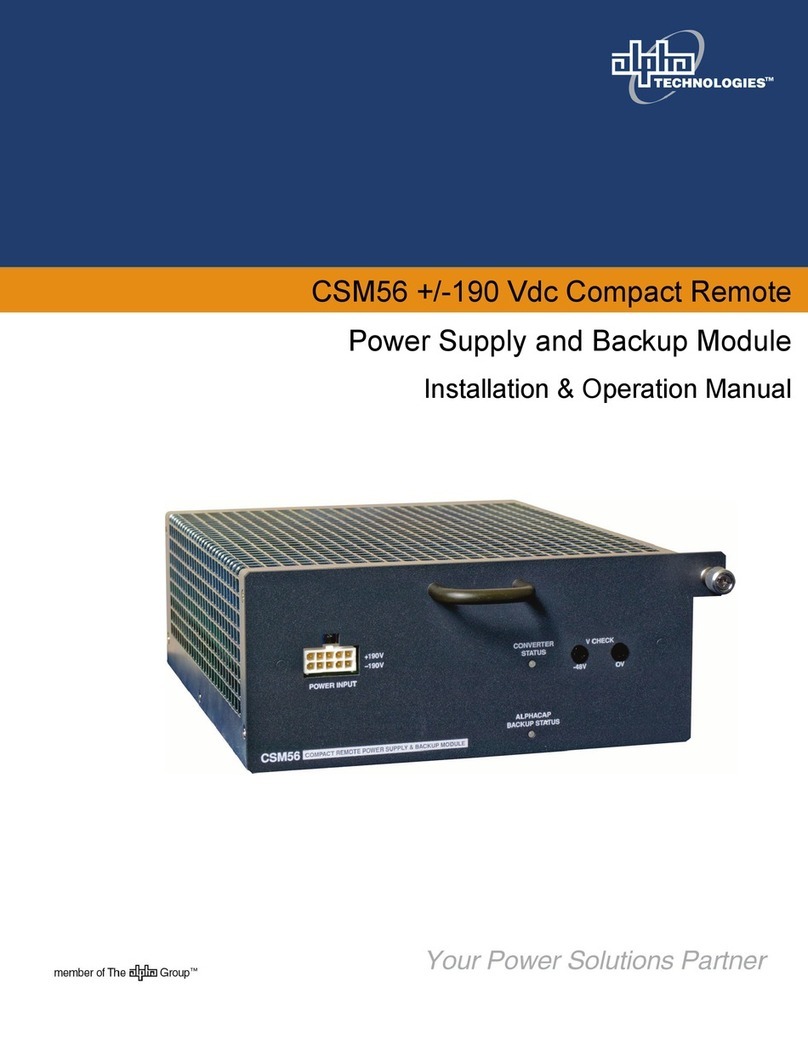

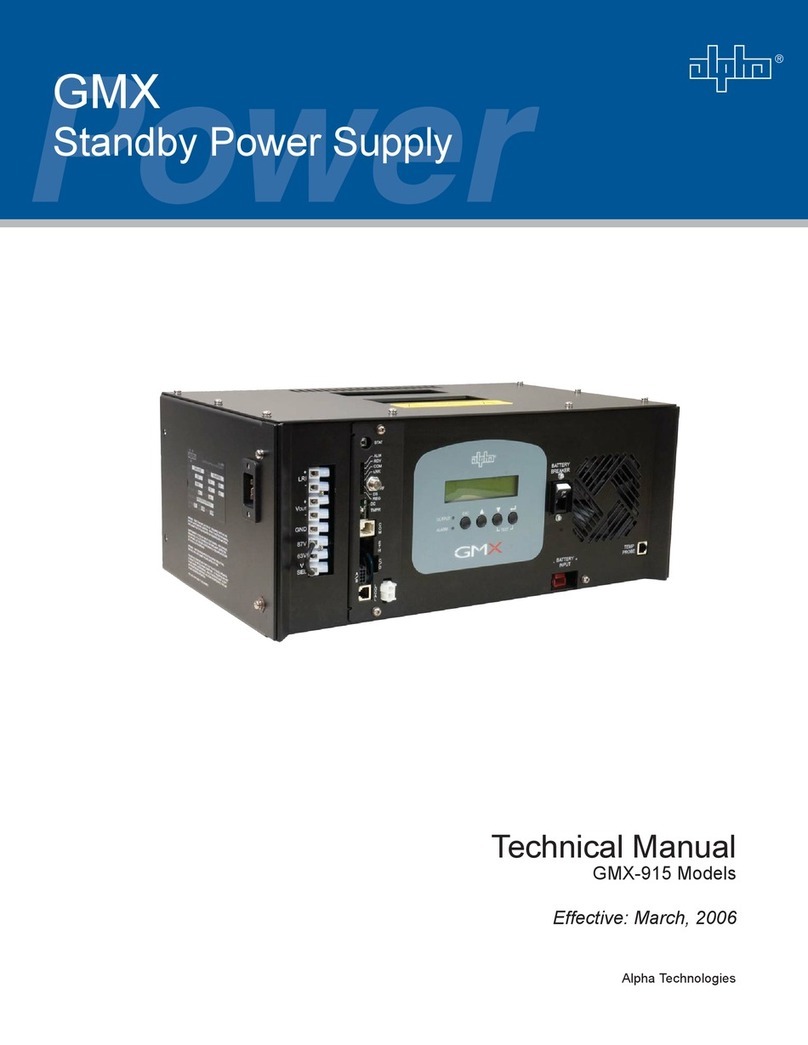

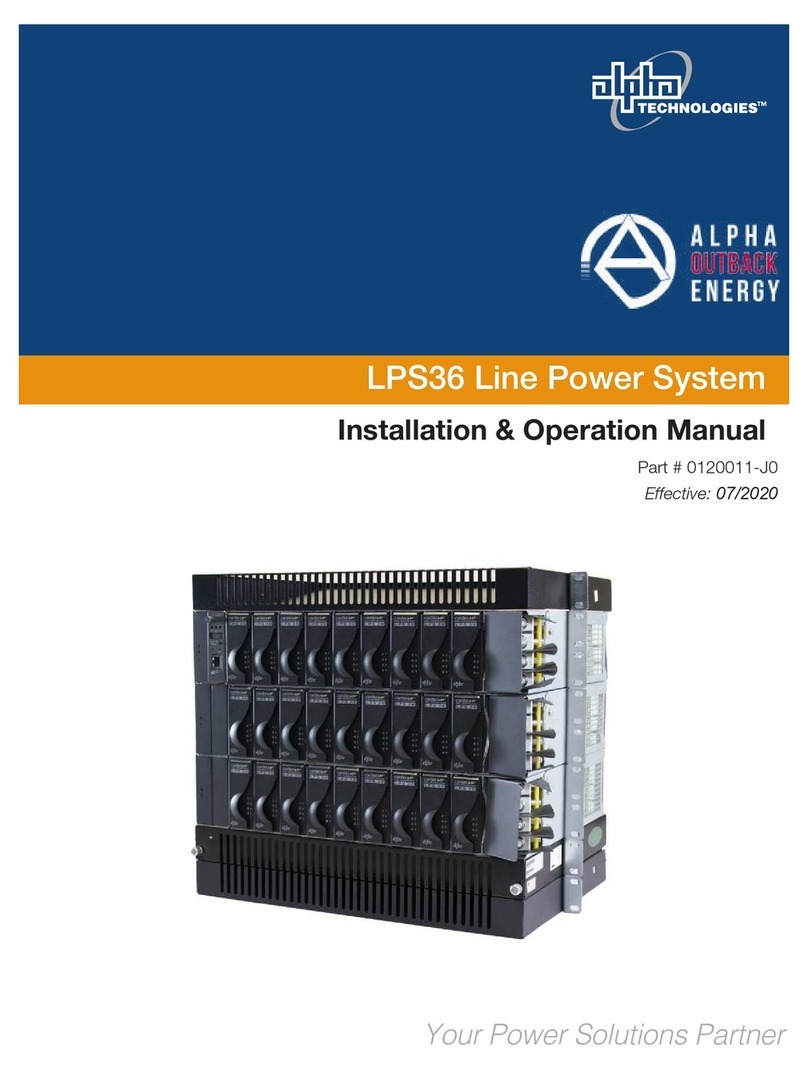

1.1 Product Overview.......................................................................................................................................... 1

1.2 Specifications ................................................................................................................................................ 2

2FEATURES ................................................................................................................................................................... 3

2.1 Cordex Integrated System Controller (CXCI+) ............................................................................................. 3

2.2 Analog Input Channels.................................................................................................................................. 4

2.3 Digital Input Channels ................................................................................................................................... 4

2.4 Alarm and Control Output Relays ................................................................................................................. 4

2.5 Network Connection and Remote Communications ..................................................................................... 4

2.6 Rectifiers ....................................................................................................................................................... 5

2.7 True Module Fail Alarm................................................................................................................................. 6

2.8 Heat Dissipation ............................................................................................................................................ 6

2.9 Over Temperature Protection ....................................................................................................................... 6

2.10 Wide AC Range ............................................................................................................................................ 6

2.11 AC Inrush/Transient Suppression ................................................................................................................. 6

2.12 Soft Start ....................................................................................................................................................... 6

2.13 Current Limit/Short Circuit Protection ........................................................................................................... 6

2.14 High Voltage Shutdown (HVSD) ................................................................................................................... 7

2.15 Battery Eliminator Operation......................................................................................................................... 7

2.16 CAN bus........................................................................................................................................................ 7

3INSPECTION.................................................................................................................................................................. 8

3.1 Packing Materials.......................................................................................................................................... 8

3.2 Check for Damage ........................................................................................................................................ 8

4INSTALLATION .............................................................................................................................................................. 9

4.1 Safety Precautions ........................................................................................................................................ 9

4.2 PSU Preparation/Mounting ........................................................................................................................... 9

5WIRING AND CONNECTIONS ........................................................................................................................................ 11

5.1 Tools Required............................................................................................................................................ 11

5.2 Power System Chassis Ground and DC Ground Reference ...................................................................... 11

5.3 AC Feeder Protection/Sizing....................................................................................................................... 11

5.4 AC Input ...................................................................................................................................................... 11

5.5 Wiring Schematic ........................................................................................................................................ 12

5.6 Calculating Output Wire Size Requirements............................................................................................... 12

5.7 DC Output ................................................................................................................................................... 12

5.8 Network Connection and Remote Communications via CXCI+.................................................................. 13

5.9 Signal Wiring Connections .......................................................................................................................... 13

6OPERATION................................................................................................................................................................ 17

6.1 Main Rectifier States ................................................................................................................................... 17

6.2 Main Rectifier Modes .................................................................................................................................. 18

6.3 400W Rectifier Factory Ranges and Defaults............................................................................................. 19

6.4 650W Rectifier Factory Ranges and Defaults............................................................................................. 19

7SYSTEM STARTUP ...................................................................................................................................................... 20

7.1 CXC Reset .................................................................................................................................................. 20

8MAINTENANCE ........................................................................................................................................................... 22