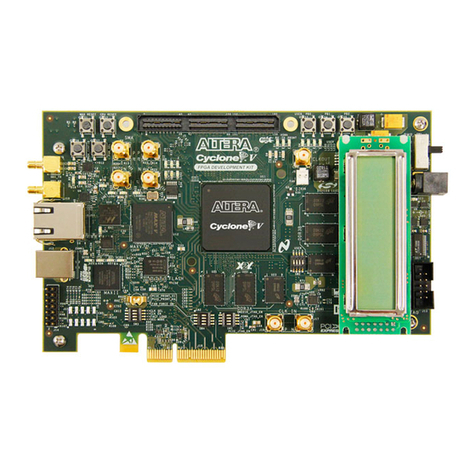

Altera Cyclone V User manual

Other Altera Microcontroller manuals

Altera

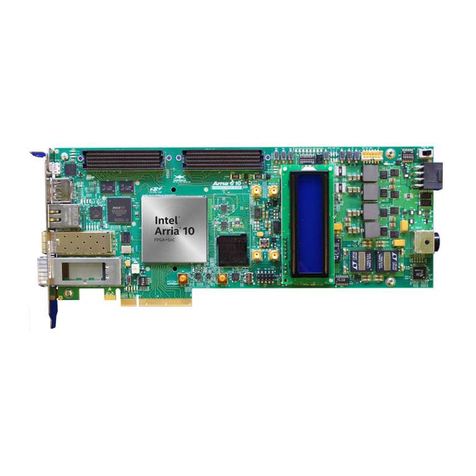

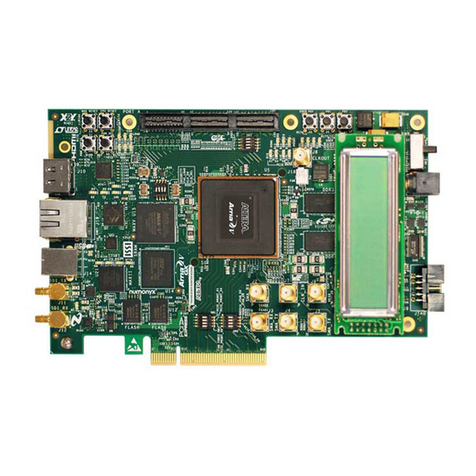

Altera Arria 10 FPGA User manual

Altera

Altera Stratix V GX FPGA User manual

Altera

Altera DE5-NET User manual

Altera

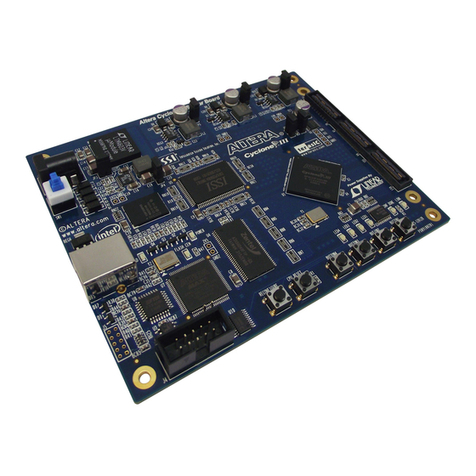

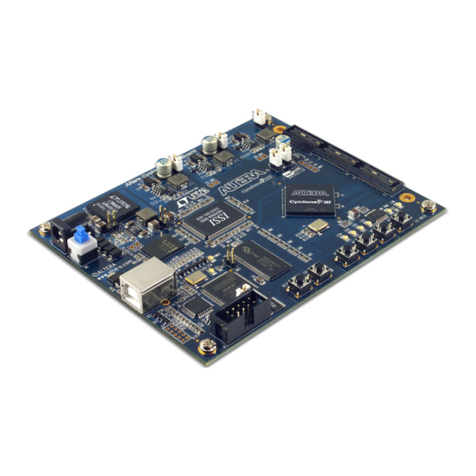

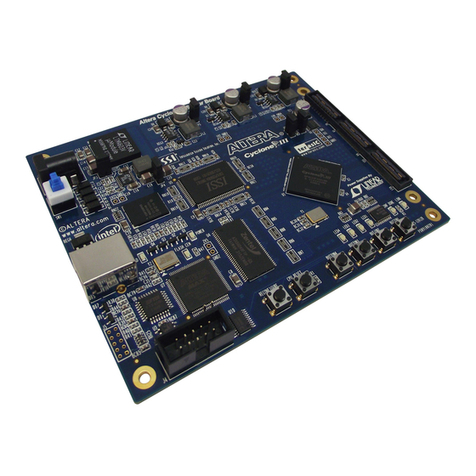

Altera Cyclone III User manual

Altera

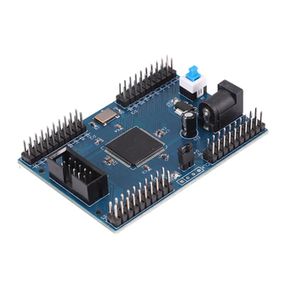

Altera Max II User manual

Altera

Altera Arria V GX FPGA User manual

Altera

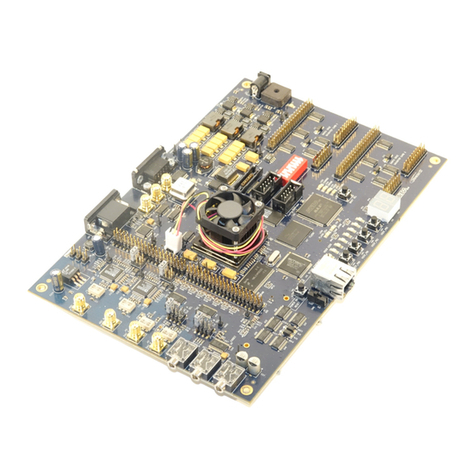

Altera DSP Development Kit User manual

Altera

Altera Cyclone III FPGA User manual

Altera

Altera Arria II GX FPGA User manual

Altera

Altera Stratix V GX 100G User manual

Altera

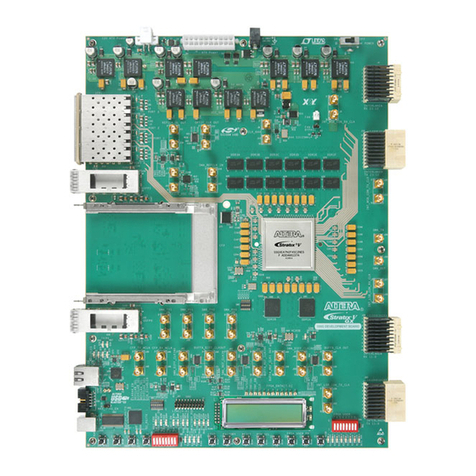

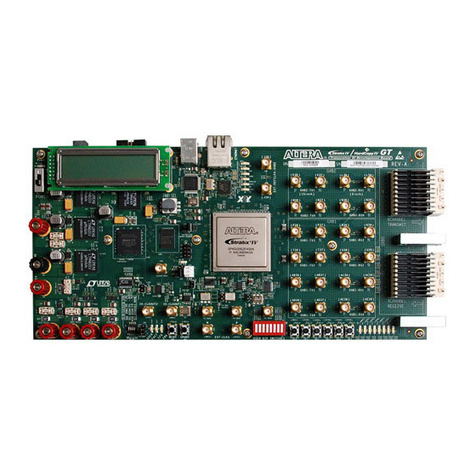

Altera Stratix IV GT Edition User manual

Altera

Altera Cyclone V GX FPGA User manual

Altera

Altera Stratix 10 GX FPGA User manual

Altera

Altera Stratix IV GX User manual

Altera

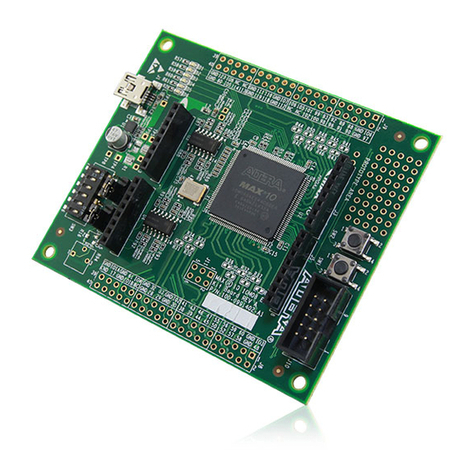

Altera MAX II Micro Kit User manual

Altera

Altera Cyclone III User manual

Altera

Altera Max10 FPGA User manual

Altera

Altera Stratix V GX Edition User manual

Altera

Altera Excalibur APEX 20K200E User manual

Altera

Altera Nios II User manual

Popular Microcontroller manuals by other brands

DIGITAL-LOGIC

DIGITAL-LOGIC MICROSPACE manual

Texas Instruments

Texas Instruments TMS320F2837 D Series Workshop Guide and Lab Manual

CYPRES

CYPRES CY14NVSRAMKIT-001 user guide

Espressif Systems

Espressif Systems ESP8266EX Programming guide

Abov

Abov AC33M8128L user manual

Silicon Laboratories

Silicon Laboratories C8051F800 user guide