20 Gear Drive, Plymouth Ind. Park, Terryville, CT 06786

Tel: (860) 585-1254 Fax: (860) 584-1973 http://www.amci.com

Networked Indexer/Driver User Manual

TABLE OF CONTENTS

5

Reference: General Installation

Guidelines

Grounding ................................................ 89

Grounding Electrode System ......... 89

Ground Bus .................................... 89

Grounding Electrode Conductor .... 90

Grounding Wires ........................... 90

Avoiding Grounding Problems ................ 90

Surge (EMI) Suppression ......................... 91

Incoming Power ............................ 91

Inductive Loads ............................. 92

System Environment ..................... 92

System Layout Considerations ................ 92

Wiring Categories for the

SD17060E2 or SD31045E2 ........ 92

Minimize Voltages in the

System Enclosure ........................ 93

Power Supply Sizing ..................... 93

Component Placement ................... 93

Conduits to Enclosure .................... 94

Installing an AMCI Networked Driver .... 94

Task 1: Installing an AMCI

Networked Driver

Location ................................................... 95

Safe Handling Guidelines ........................ 95

Prevent Electrostatic Damage ........ 95

Prevent Debris From

Entering the Unit ......................... 95

Remove Power Before Servicing .. 95

Airflow and Wiring Space ....................... 95

Outline Drawings ..................................... 96

SD17060E2 Outline Drawing ........ 96

SD31045E2 Outline Drawing ........ 97

Mounting Methods ................................... 97

Grounding and Powering the System ...... 98

Installing the Stepper Motor .................... 99

Outline Drawings ........................... 99

Mounting the Motor ...................... 99

Connecting the Load ...................... 99

Extending the Motor Cable ........... 99

Installing the Motor Cable ............. 99

Connecting the Motor .............................. 100

Motor Connector ........................... 100

Interlock Wiring ............................ 100

Motor Wiring ................................. 101

Task 1: Installing an AMCI Net-

worked Driver (continued)

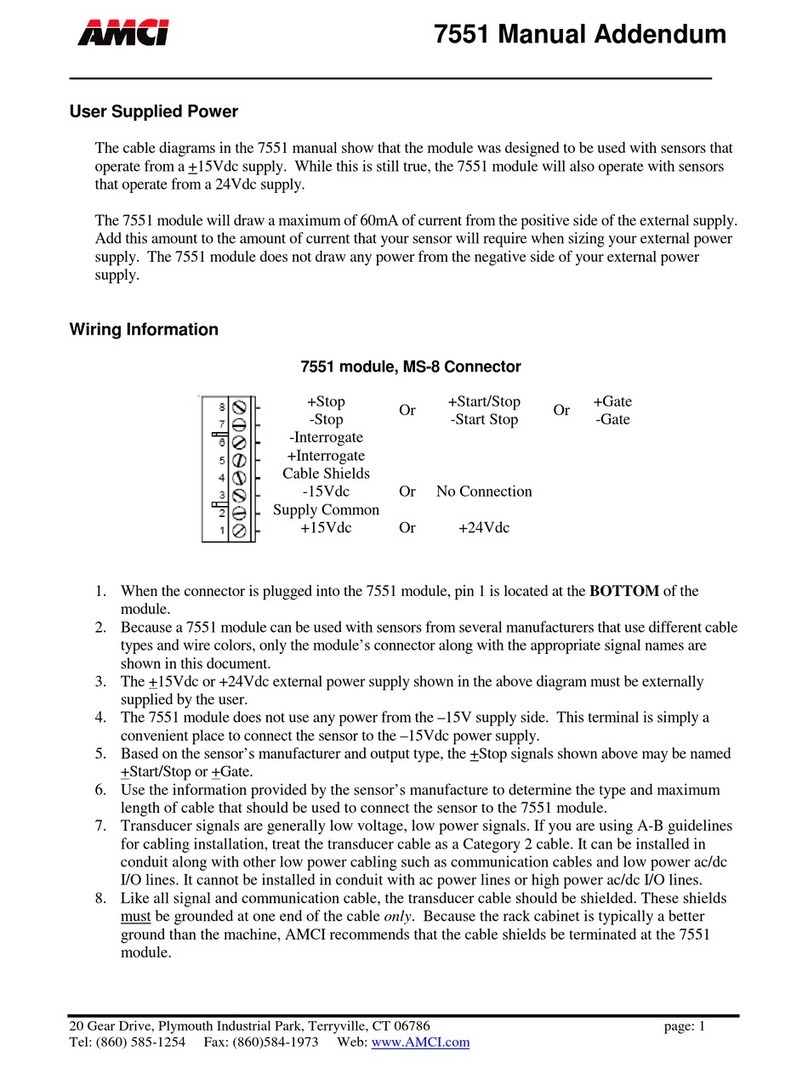

Digital Input Wiring ................................. 102

Cable Shields ................................ 102

Input Wiring .................................. 102

Output Wiring ............................... 103

Encoder Wiring ............................. 103

Ethernet Connections ............................... 104

EtherNet/IP Connections .......................... 104

Non-DLR Applications ................. 104

DLR Applications ......................... 104

PROFINET Connections .......................... 104

Non-MRP Applications ................ 104

MRP Applications ......................... 104

Modbus TCP Connections ....................... 105

Task 2: Set the IP Address

Determine the Best Method for

Setting the IP Address ............................ 107

Use Factory Default Settings ................... 107

Use the Embedded Web Server ................ 108

Use the AMCI NET Configurator

Utility ..................................................... 111

Task 3: Using the EDS File with

EtherNet/IP

Problems On Some Systems .................... 115

Obtain the EDS file .................................. 115

Install the EDS file ................................... 115

Start the EDS Hardware

Installation Tool .......................... 115

Install the EDS File ....................... 116

Configure the Ethernet Adapter

on Your PLC .......................................... 118

Add the SD17060E2 or SD31045E2

to Your Project ....................................... 118

Configure the SD17060E2 or

SD31045E2 Driver ................................. 119

General Tab ................................... 119

Connection Tab ............................. 119

Configuration Tab ......................... 119

Buffering the I/O Data ............................. 120

Task 4: Implicit Communications

Without EDS

Host System Configuration ...................... 121

Adding the SD17060E2 or SD31045E2 .. 121

Configuring the SD17060E2 or

SD31045E2 ............................................ 123

Buffering I/O Data ................................... 124