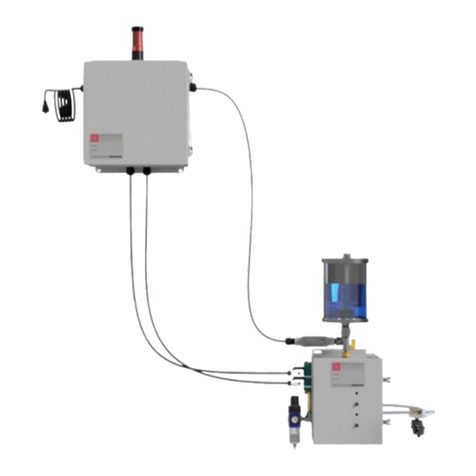

3049B AUTOMATIC BUTT DISCARD LUBRICATION SYSTEM OPERATOR’S MANUAL PAGE | 5

Installation

1. Review complete system to ensure that damage has not occurred in shipment.

2. Manually operate the system outside of the press area. This can be completed by

connecting all components as per the schematic provided, connecting plant air to the

valve package, and then pressing the manual actuation buttons located on the side of the

Norgren 3-way valves located on the Valve Package. All components will come in preset

according to the System Settings recommended in this bulletin. During manual operation, it

should be confirmed that these components are set accordingly and the spray volume and

pattern is acceptable. In the event that the settings specific to your operation vary from

those recommended by AMCOL, these should be recorded and controlled for later access

and training.

3. With the press in normal operating conditions and standing outside of the press guarding,

observe potential areas for installation of the nozzles, reservoir, and valve package. The

nozzles will have to fit without being hit by moving components of the press. The valve

package will have to be outside the press guarding and ideally within sight of the operator

and spray nozzles, yet out of general traffic area. The reservoir should also be outside of the

press guarding and close to the valve package

4. Lock and Tag the press. Then place the atomizing nozzle assemblies in the expected

position without the hose attachments in order to properly assess and approve the exact

placement of them. Exit the lock and tag area and reactivate the press with the nozzle in

position in order to determine that the nozzle is in a position so as to avoid damage during

normal press operation. Once the exact location is determined, mark the location or

permanently mount the nozzles accordingly for future reference and placement after

servicing or other movement of the nozzle and spray assembly. Hints for placement:

A. Butt Shear – on the press platen, shear housing, or top of the container (with fan

spray).

B. Log Shear – on the press platen from the exit side of the shear.

5. Permanently mount the liquid air manifold block above the spray nozzles such that it is

located within seven feet (7’) of both atomizers. Also, be sure the manifold block is visible

from outside the lock and tag area in order to allow for system inspection and monitoring

during normal press operation.

6. Mount the Valve Package as previously determined. The Valve Package air and liquid

outlets must be within fifteen feet (15’) of the liquid and air manifold, which has already

been installed on the press.

7. Connect a lightly lubricated ½” air line to the air inlet of valve package. Be sure that this

air source is properly locked and tagged prior to beginning your installation. Do not

energize until all hoses have been properly installed and attached.