American Flame AFVK-SP Valve Kits REV. 10-8-19 Page 9

OPERATION FEATURES

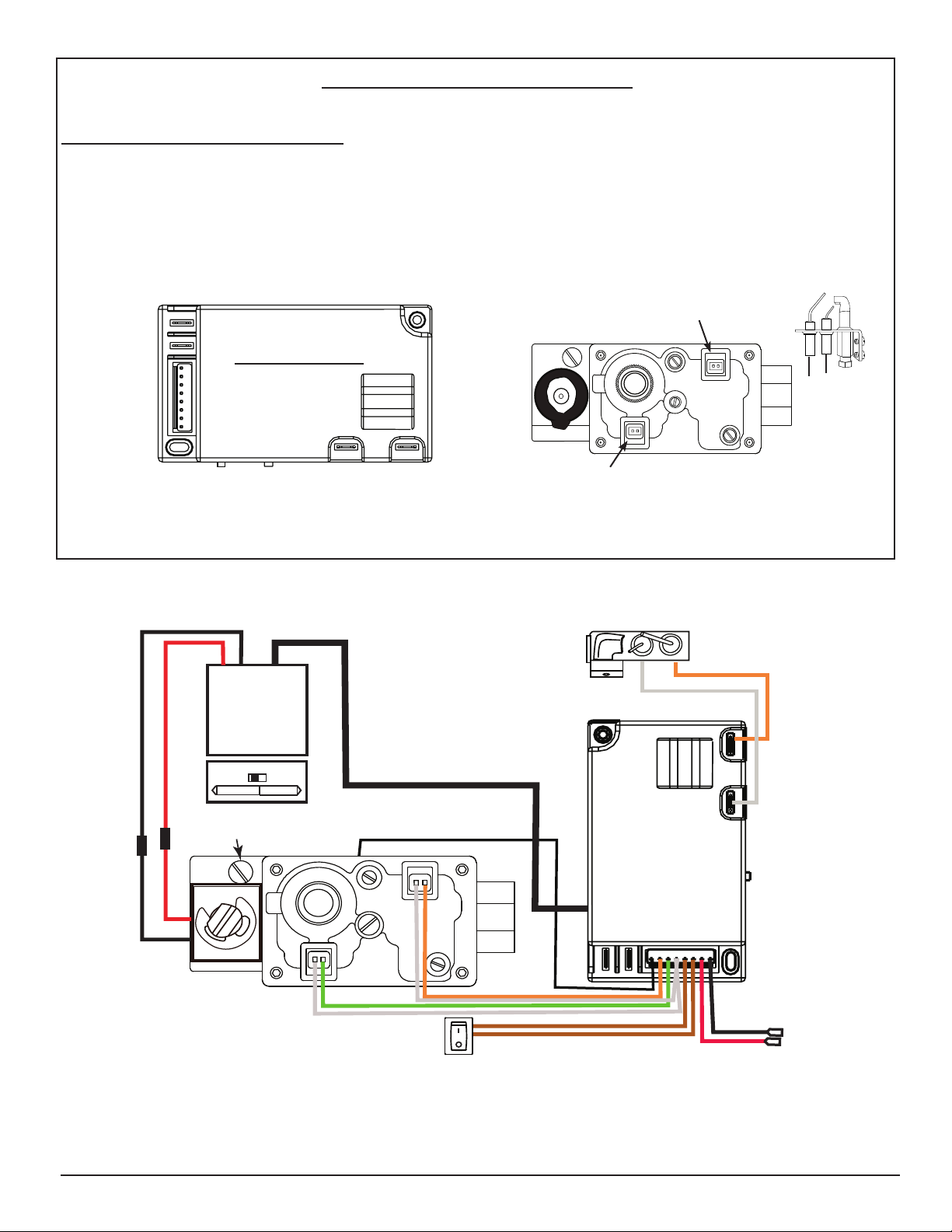

Special Features of the valve kits control module

All valve kits modules have (2) special features built into the system as follows:

1. CONTINUOUS PILOT FEATURE:

The AFVK-SP, AFVK-SP-HL & AFVK-SP-MHL valve kits have a continuous pilot

feature that may be activated in cold climate conditions or to maintain a draft in

the chimney. The continuous pilot can be activated by the

following two methods.

1.Switch on the Front Valve Kit

The Continuous Pilot feature may be activated by placing the

”Off/Continuous Pilot” switch located on the front of the valve kit in the

“Continuous Pilot” position. See Fig. 20. When this switch is turned to the

Continuous pilot position the pilot will immediately begin sparking to light the pilot

and the pilot will remain ON.

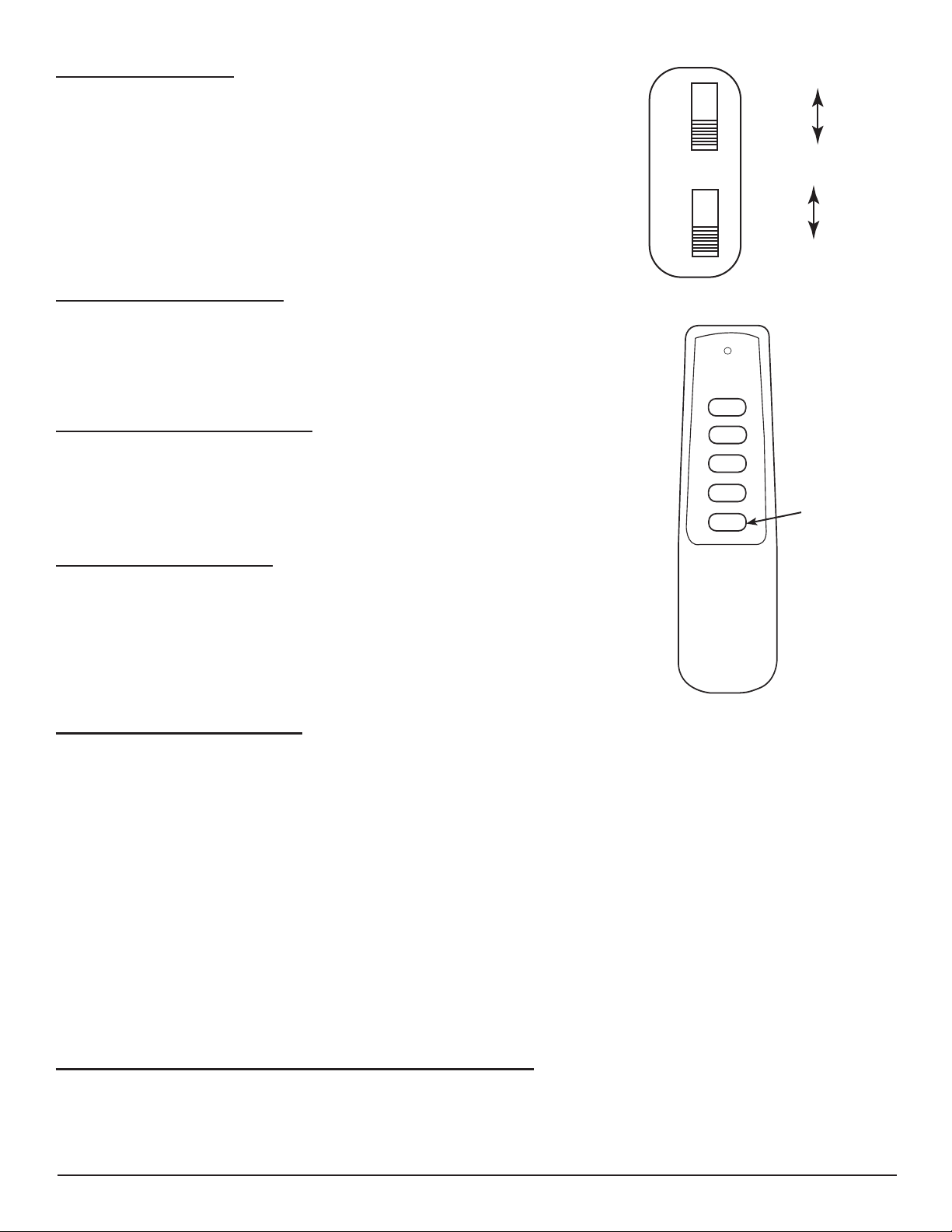

2.Button on the Hand Held Remote

To use the continuous pilot feature from the hand held remote control

ensure the “Off/Remote” switch on the front of the valve kit is in the

“remote” position. See Fig. 20. Simply press the button on the hand held remote

marked “Continuous Pilot” (See Fig. 21). The pilot will immediately begin sparking

to light the pilot and the pilot will remain ON.

Note: 7-Day On-Demand Pilot

When the control module is set in the Continuous Pilot mode (either manually or

by remote control), a 7-day countdown timer will be started. After 7-days if the

main ame has not been turned ON, the control module will turn the pilot OFF. If

the main ame is turned ON during the 7-day countdown, the timer is reset and

the cycle restarted again.

ON

OFF

HI

LOW

Continuous Pilot

ON/OFF

OFF

REMOTE

ON

OFF

CONTINUOUS

PILOT

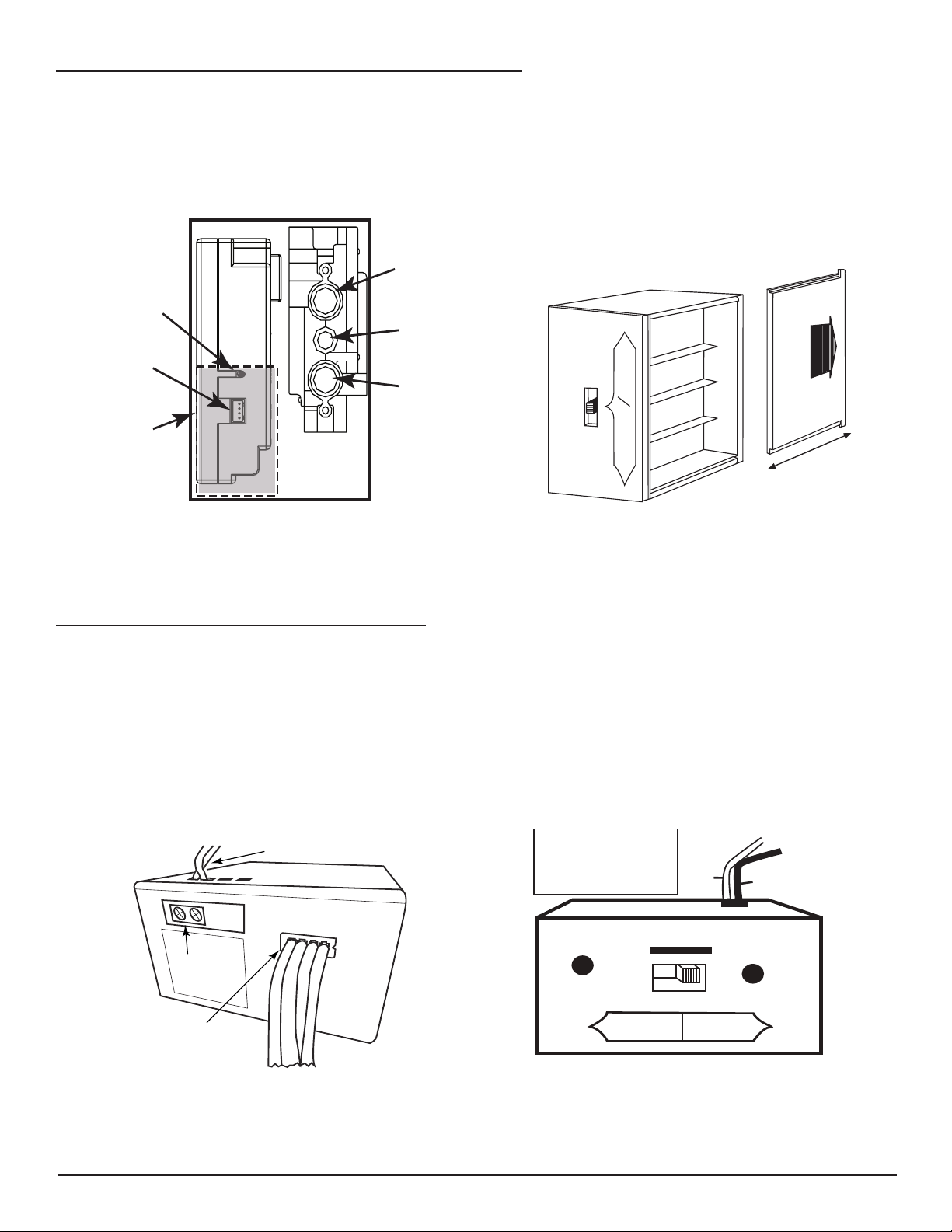

Fig. 20 Valve box switches

Fig. 21 Remote control

Continuous button

2. REMOTE CONTROL FEATURE:

The AFVK-SP, AFVK-SP-HL, or AFVK-SP-MHL comes with a remote control transmitter. This remote is already

programmed to operate your valve kit directly out of the box.

The valve kit module has a built in remote control receiver that allows the user to program a hand held remote transmitter

to the appliance at any time during or after installation of the appliance.

1. There is a switch located on the front of the valve kit face plate that reads OFF/REMOTE. See Fig. 20.

2. When the OFF/REMOTE switch is in the OFF position the valve kit will operate from the rocker switch in the center of

the face plate. Note: Fig. 13 page 6 (“O” is Off and “I” is for Ignite)

3. When the OFF/REMOTE switch is in the REMOTE position the appliance will operate from the Remote Control

transmitter. Note: The valve kit module must be programmed to the Remote Control transmitter.

4. If needed, program the module (Make sure the batteries have been installed in the battery pack). Locate the learn

button on the module (See Fig. 14). Press and release the learn button there will be a beep sound from the

module. Then press any button on the remote transmitter. Once the modules internal receiver accepts the

transmitter code, there will be a series of rapid beeps.

5. The remote system is ready for use.

MAINTENANCE OF YOUR AFVK-SP SERIES VALVE KIT SYSTEM

1. Your system should be checked once a year (At the start of the heating season) for proper operation by a qualied

service representative.

2. Replace all batteries at the start of the season. Items to check: electronic valve operation, Spark to pilot operation,

ON/OFF switch operation, damper operation, visual check of the burner and gas connections for leaks.