•Stainless steel remote electrical enclosure

•Hinged catch pans on underside of proofer with

key latch

•Reverse axis rounder

•Chilled rounder bed

•Non-stop magnetic pan indexer kit

•Pneumatic rotary gate upgrade

•Servo rotary gate upgrade

•Additional proofer sections

•CE confirmed electrical package

•Allen-Bradley® 5/04 PLC upgrade

•Second Allen Bradley® PanelView 1000

operator interface at moulder

•Panel Modem Option

•Panel air conditioner

•3’ infeed pan conveyor extension for hand feed

•3’ discharge pan conveyor extension

•UHMW moulder board assemblies

•Twin Roll Cutter

•Zig-zag vacuum flour reclaim system with

stainless steel flour catch pan with integral

design to zig-zag for flour containment

and recycling

•Pan Dust Collector

•Accupan four point flour reclaim system

•Magnetic pan pre-indexer conveyor

•Stainless steel proofer support legs

•Roll imprinters

•Pan shakers

•Bun seeders

•Tool kit

•Spare parts kit

ACCUPAN BUN SYSTEM

Specifications

Options

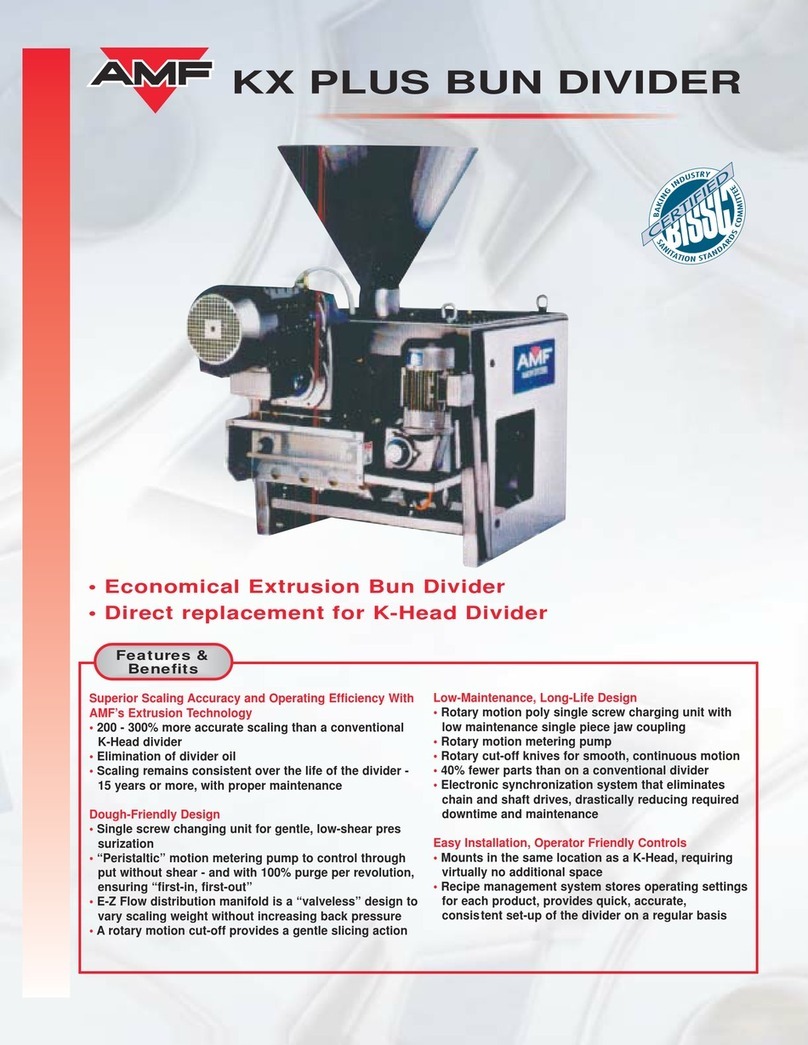

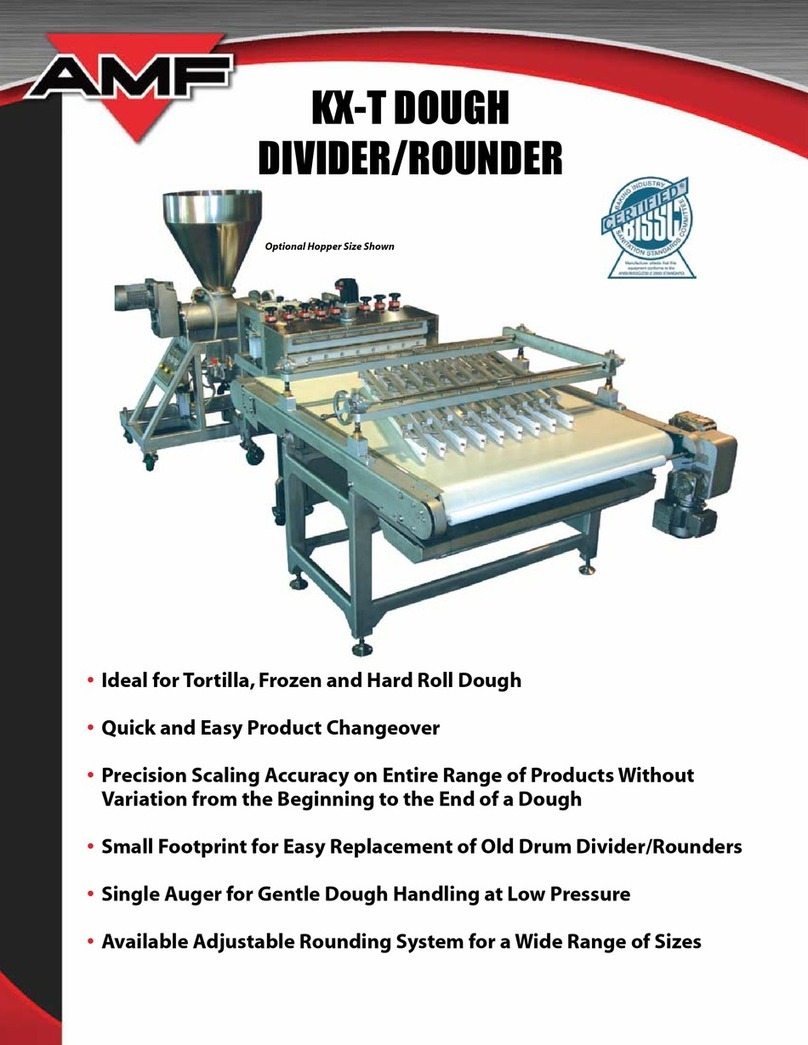

KX Plus Divider

KRDIIe Divider

Configuration Divider Speed Maximum Scalling

type Range Throughput Range

(Cut per minute) (lbs./hr.)

Accupan AccuMax 4 across/6 across AccuMax 40-125* 6000/8000* 1-5 oz*

Accupan KRDlle4/ KRDlle6 4 across/6 across KRDlle 40-115* 5000/6000* 7/8- 6 oz*

Accupan KX+4/KX+6 4 across/6 across KX Plus 40-125* 5000/6000* 1-5 oz*

* Throughput, maximum speed, and scaling range are dependent or several factors including dough

condition, product configuration, and other associated equipment.

Magnetic Pan Indexer Servo Rotary Gate

AccuMax Divider

Proofer Side Panels

and Catch Pans

The Accupan Bun System is supplied with one NEMA

4 rated operator control station :

•On the side of the tower

Allen Bradley PanelView® 1000 keypad operator

interface with alarm messages and recipe management

on operator panel to control:

•Divider

•Rounder belt speed

•Rotary gate speed

•Pulse zig-zag flour sifter speed

•Proofer speed

•Sheeter Roller speed

•Moulder Belt speed

•Pulse moulder sifter speed

• Hot dog gate phasing and speed

•Magnetic pan indexer

•Flour recovery (if so equipped)

Allen Bradley pushbuttons on operator

panel for:

•Two-button start

•Stop

•Emergency stop

•Master relay control

Operator station at S/M/P with Allen Bradley button

controls for :

•Pan Gate Control

•Pan Indexer Auto/Stop/Jog

•Two-button start

•Master Control Relay

•Stop/Emergency stop

•Sheeter/Moulder Belt/Pan Conveyor speed

adjustment with LED readout

NEMA 12 remote enclosure (painted steel) including:

•Main disconnect switch

•Full voltage magnetic NEMA rated starters

•Allen Bradley 5/03 PLC control

•Toshiba inverters

Electrical

Features

Mechanical

Features

ACCUPAN BUN SYSTEM

•Designed and manufactured in accordance with

BISSC quality and sanitation standards

•Heavy duty stainless steel frame for durability and

corrosion resistance

•Poly Slick Rounder Belt

•Hinged rounder bar frame with gas spring assist

•NEW Spiral Tunnel Rounder Bars

•Direct drive rounder belt

•Cantilevered rounder frame design for quick

belt changes

•Adjustable feet with lagging capability

•Independently driven UHMW kicker roller

•UHMW zig-zag board and lane guides

•Pneumatic flapper gate dough ball transfer system

•Pneumatic pulse sifter with linear motion at zig zag

and moulder areas

•Stainless steel flour catch pan with integral design to

zig-zag for flour containment and recycling

•Heavy duty proofer trays with stainless steel frame,

non-stick analytic plastic snap-in trays

•12’ stacked or 24’ stretched proofer configuration

•Punched stainless steel proofer side panels

•Single action flapper gate controls the drop from the

proofer into the sheeter

•6”diameter sheeter rollers

•Open design sheeter drive for easy maintenance

•Cantilevered moulder belt frame design for easy

belt access

•Synthetic/cotton-topped moulder belt for flour reten-

tion and stretch resistance

•Pneumatic driven hot dog gates with PLC control for

on-the-fly adjustment

•Rotary pan indexer for smooth pan indexing and

quick change index bars for easy product

changeover (magnetic indexing is available as

an option)

Operator Interface Panel

Hinged Rounder Bars with

Gas Spring Assist

Rotary Pan Indexer