S100

1-9

Revised 10/2005

e - mail service @amfreece.cz, parts @amfreece.cz, website: www.amfreece.com

Phones: +420 582 309 146 (service), +420 582 309 286 (spare parts), Fax +420 582 360 606

A-INTRODUCTION

1.Introduction .......................................................................................................................... 1-1

2.Specifications........................................................................................................................ 1-2

3. Safetyofwork ...................................................................................................................... 1-3

4.Securityof the operator andmaintenance............................................................................... 1-4

5.Listof the safetylabelsanddevices ....................................................................................... 1-6

6.Positionof the labelsandthesafetydevices ........................................................................... 1-7

B - MACHINE INSTALLATION

1.Contentofthe shipping box ................................................................................................... 1-8

2.Accessories. ......................................................................................................................... 1-8

3.Machineunpacking andassembling ....................................................................................... 1-9

4.Adjustment of theT-Belt tension for sewing ......................................................................... 1-12

5.Adjustment of theleftT-belttension..................................................................................... 1-13

6.Threadstandinstallation. ....................................................................................................... 1-14

C - OPERATOR INSTRUCTIONS

1.Preparing toSew .................................................................................................................. 1-15

2.NeedleInstallation ................................................................................................................ 1-16

3.Threading ............................................................................................................................. 1-16

D- MACHINEADJUSTMENTS

1.Stitchesdensityadjustment .................................................................................................... 1-19

2.Adjustmentofthestitchesdensity in the eye ........................................................................... 1-22

3.Adjustment ofthe stitchesdensityincrossbar ........................................................................ 1-22

4.Lengthsofthesewing ............................................................................................................ 1-23

5.Changeof thebuttonholeshape- changeofthelateral cam .................................................... 1-24

6.Changeof the widthbite........................................................................................................ 1-25

7.Principlesofsewing............................................................................................................... 1-28

8.Bedplatealignment ............................................................................................................... 1-34

9.Testingthecamposition ........................................................................................................ 1-34

10.Turningmechanism .............................................................................................................. 1-35

11.Stoppingmechanism............................................................................................................ 1-37

12.Setting-upthemechanismforfabricclamping ..................................................................... 1-39

13.Clampplate spreading......................................................................................................... 1-40

14.Lengthsetting -upofthe second buttonholerow ................................................................. 1-41

15.Eye shape control ............................................................................................................... 1-41

16.Needle bar height................................................................................................................ 1-42

17.Clearance Betweenthe Looper andthe Needle ................................................................... 1-43

18.Spreaders adjustment.......................................................................................................... 1-44

19.Loopersmovement ............................................................................................................. 1-45

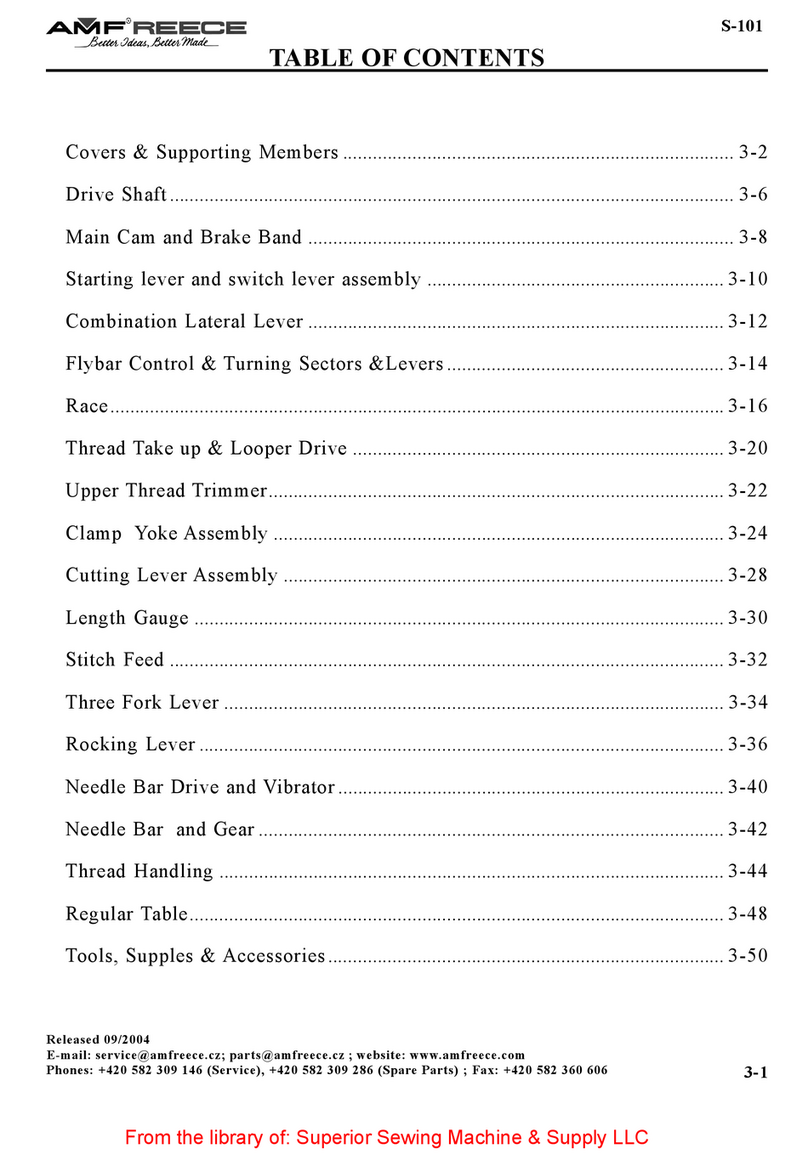

TABLE OF CONTENTS