Released: 12/2021

A - INTRODUCTION

1. BASIC INFORMATION ....................................................................................................................... 1

2. SAFETY DEVICE AND LABELS ........................................................................................................ 2

3. GENERAL MACHINE PARTS DESCRIPTIONS............................................................................... 3

4. SPECIFICATIONS............................................................................................................................... 4

5. TABLE TYPE ....................................................................................................................................... 5

6. INSTRUCTIONS FOR OPERATOR SAFETY AND MAINTENANCE.............................................. 6

7. SPECIAL ACCESSORIES.................................................................................................................. 7

B - MACHINE ASSEMBLY

1. CONTENT OF THE SHIPPING BOX................................................................................................. 9

2. ACCESSORIES................................................................................................................................... 9

3. POWER AND AIR CONNECTION ....................................................................................................11

4. HEAD PNEUMATIC .......................................................................................................................... 12

5. THREAD STAND INSTALLATION ................................................................................................... 13

C - PROPER APPLICATION

1. POWER UP / HOME POSITION ...................................................................................................... 14

2. NEEDLE INSTALLATION ................................................................................................................. 15

3. THREADING...................................................................................................................................... 16

D - MACHINE CONTROLS

1. PROGRESS OF SEWING................................................................................................................ 17

2. OPERATOR CONTROL PANEL PUSH BUTTONS AND SWITCHES ......................................... 18

3. THE PROGRAMING MENU STITCHING HEAD ............................................................................ 19

4. TESTS................................................................................................................................................ 21

5. PROGRAM VERSION ..................................................................................................................... 22

6. COUNTER RESET............................................................................................................................ 22

7. PARAMETER CHECKLIST .............................................................................................................. 23

E - MACHINE ADJUSTMENTS

1. MACHINE HOME POSITION ........................................................................................................... 24

2. MAIN CAM ADJUSTMENT............................................................................................................... 25

3. THE PRINCIPLES FOR THE MACHINE ADJUSTMENT............................................................... 25

4. NEEDLE BAR .................................................................................................................................... 26

5. BITE.................................................................................................................................................... 27

6. FEEDING ........................................................................................................................................... 29

7. SLIP CLUTCH ................................................................................................................................... 30

8. STITCH DENSITY............................................................................................................................. 30

9. ADJUSTMENT OF BARRING STITCHES ...................................................................................... 31

10. SPACE BETWEEN THE FIRST AND SECOND ROW OF STITCHES ......................................... 33

11. BUTTONHOLE LENGTH CHANGE................................................................................................. 34

12. LOOPER ADJUSTMENT .................................................................................................................. 35

13. THREAD DRAW-OFF ....................................................................................................................... 38

14. THREAD TENSION........................................................................................................................... 39

15. THREAD TRIMMING ........................................................................................................................ 41

16. MACHINE HEAD CLAMP FEET ADJUSTMENT ............................................................................ 42

17. ADJUSTMENT OF THE STOPPING SENSOR POSITION ........................................................... 43

18. CHANGING THE DRIVE BELT ........................................................................................................ 44

19. THE MAIN CAM CHANGE ............................................................................................................... 45

S-4000 ISBH Omron

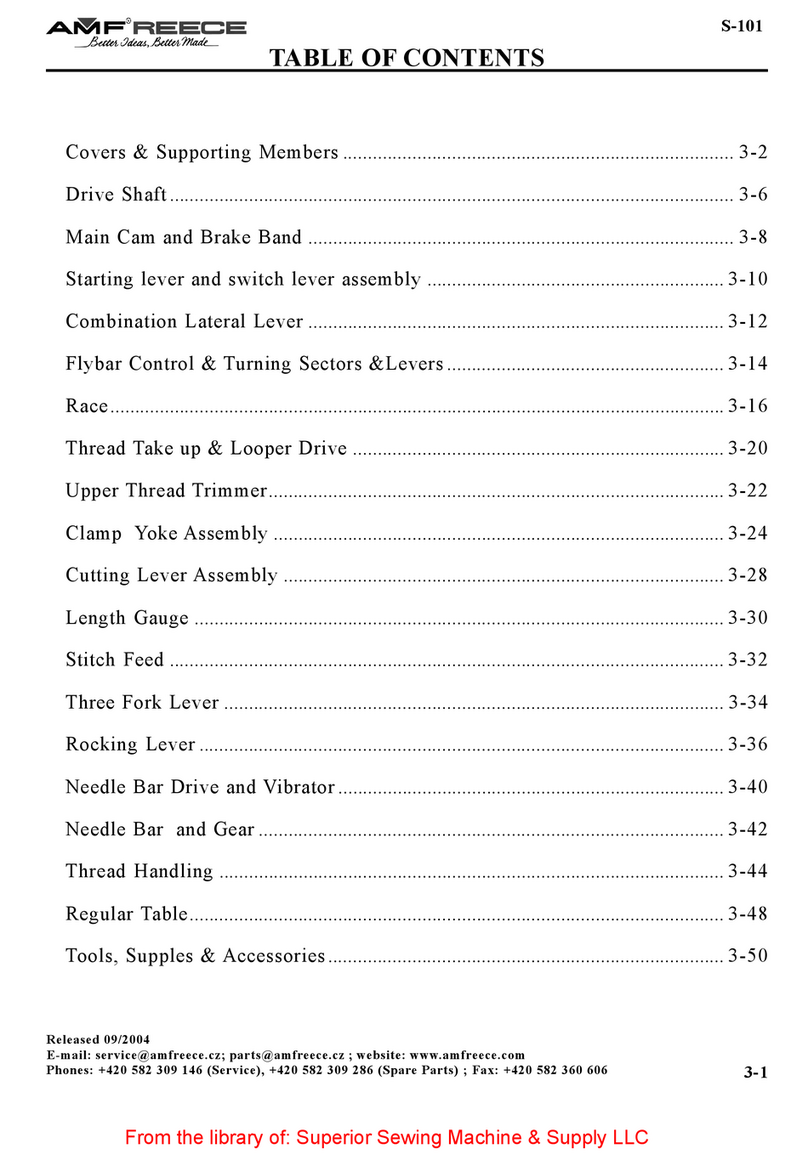

TABLE OF CONTENTS