Caution: Read before installing this product

>

>

>

>

>

>

>

>

To ensure optimal performance, please read

this guide carefully and keep in a safe place

for future reference.

Install this product in a cool, dry, clean place -

away from direct sunlight and heat sources,

vibration, chemical fumes, dust and moisture

(steam).

Do not expose this product to sudden

temperature changes or locate it in an

environment with high humidity. This is to

prevent condensation forming inside which

may cause damage to the product.

Do not clean this product with chemical

solvents as this may damage the finish. Use

a clean, dry or damp cloth.

ENVIRONMENTAL:

Before installing, ensure that the building is environmentally sealed, de-humidified and at a stable

temperature of at least 16 degrees centigrade (61 degrees farenheit)

This product should not be used with single thick coat plaster solutions or with other finshing methods that

take days (rather than hours) to dry out.

Please be aware that when this product is directly fitted into a solid wall structure (e.g when using the solid

wall backbox) vibrational energy is inevitably transferred into the solid wall structure. This energy can travel

for some considerable distance up, down and along the structure. It is therefore recommended the

product be fitted within acoustically insulated stud walls or ceiling sections where possible. The use of the

product directly embedded in solid walls is not recommended in multi occupancy buildings.

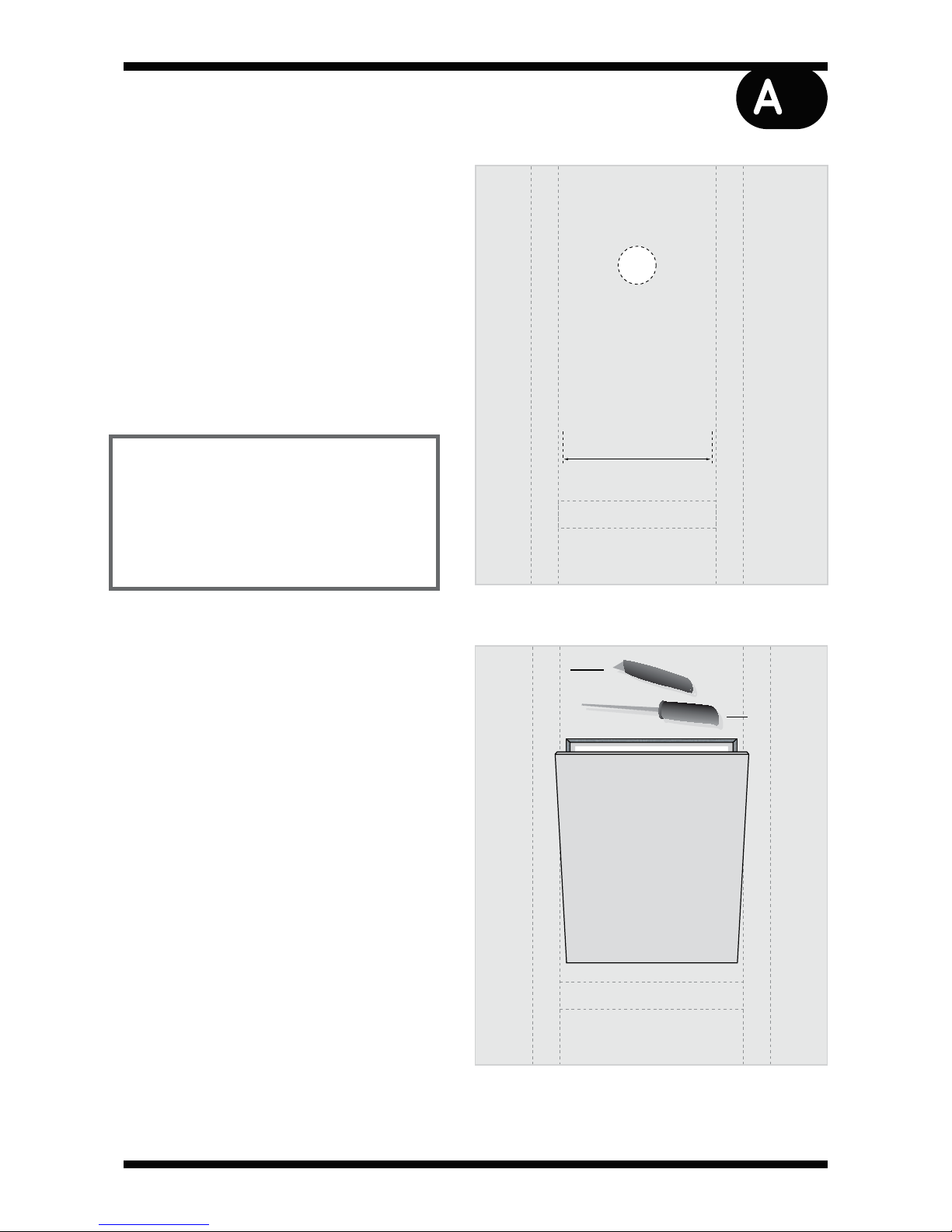

Ensure that all installation mounting surfaces

are able to support the weight of the

product.

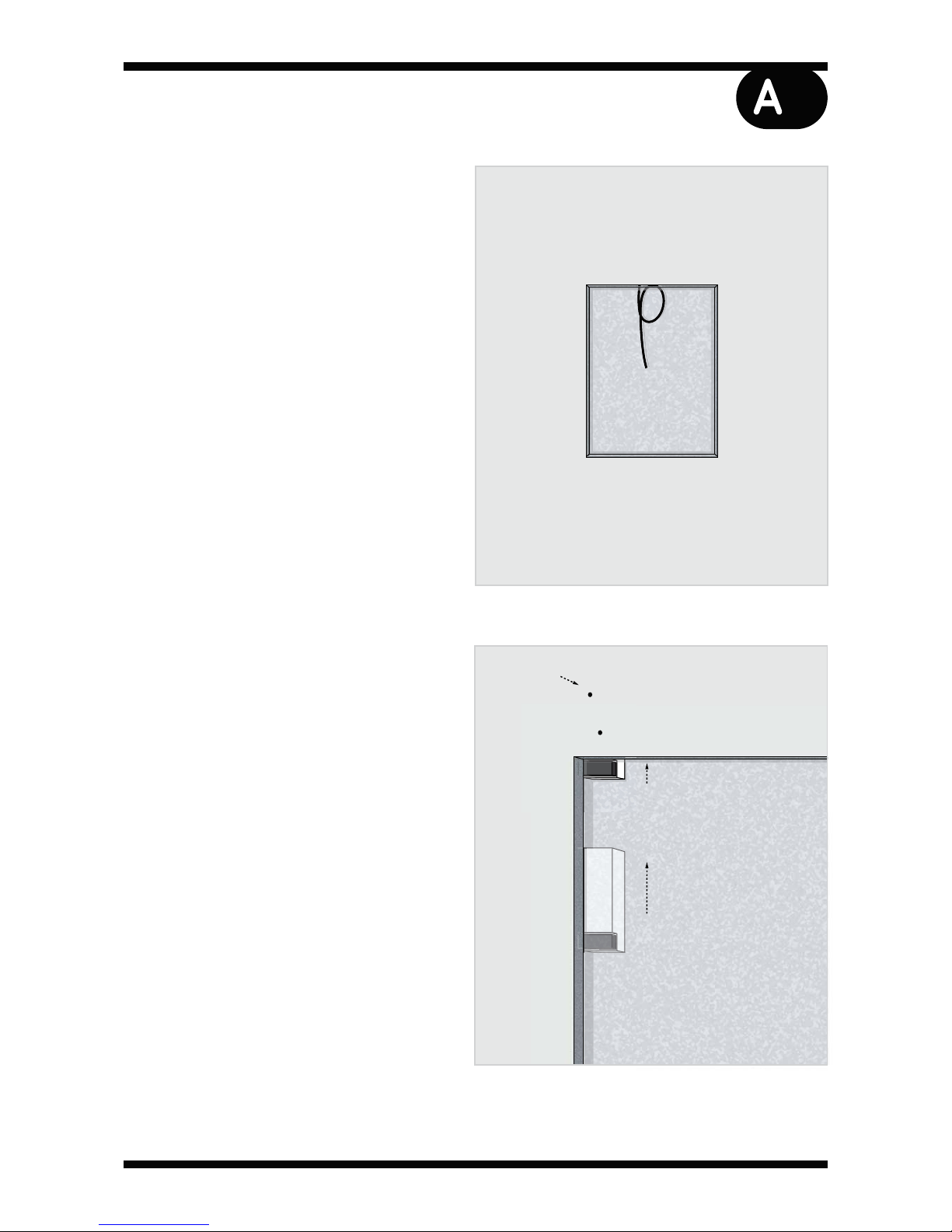

After installation, avoid pushing on the wall or

ceiling surface immediately in front of the

speaker. Excessive excursion, whilst unlikely

to damage the speaker, will undoubtedly

crack the plaster around its perimeter.

Do not attempt to modify or repair the

product. Contact your distributor or

manufacturer if a fault should occur.

The rear of the product should not be subject

to chemical cleaning and should not be

painted in any way.

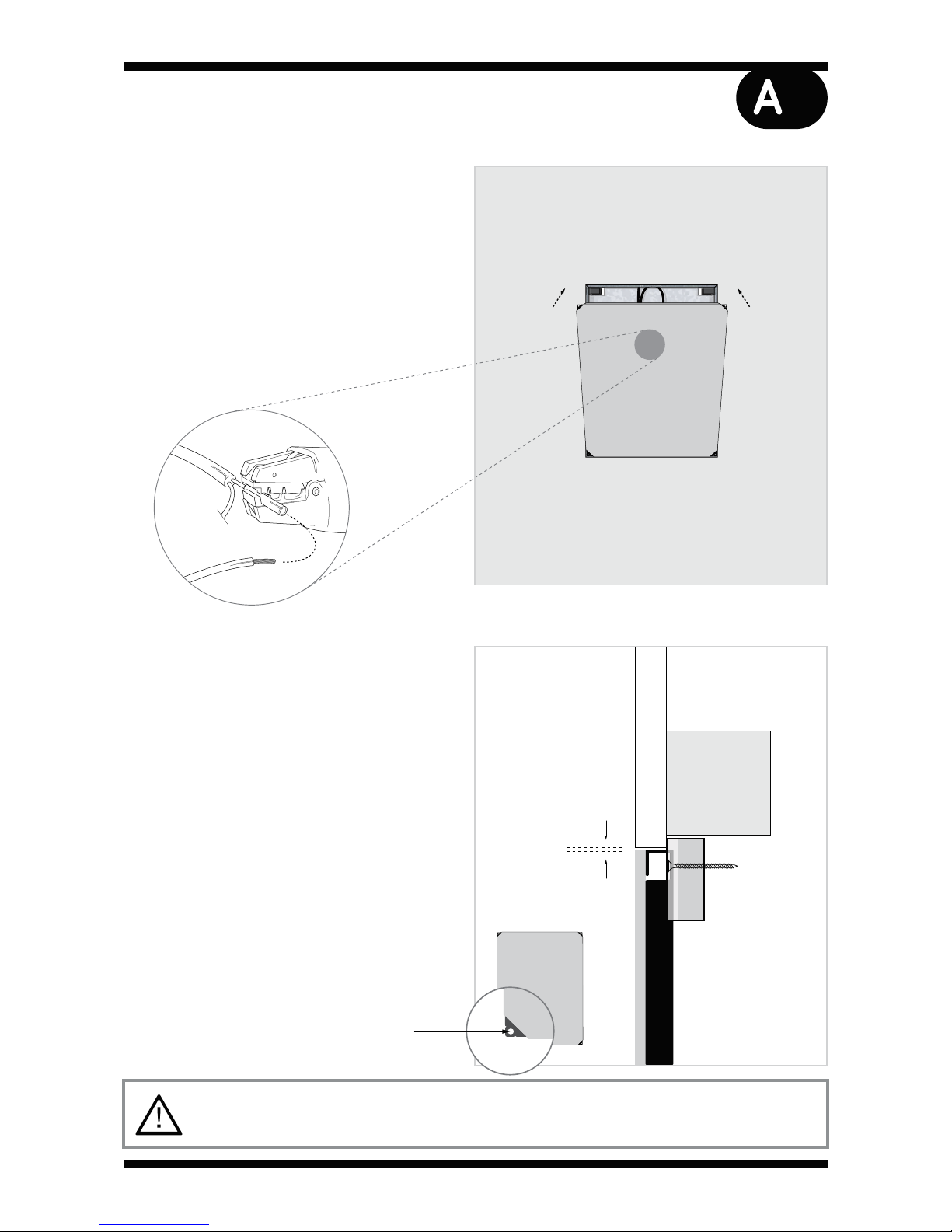

WARNING:

No attempt should be made to install this product within existing building structures unless you are certain

that no electric cables, water pipes, gas pipes or supporting joists will be cut through.