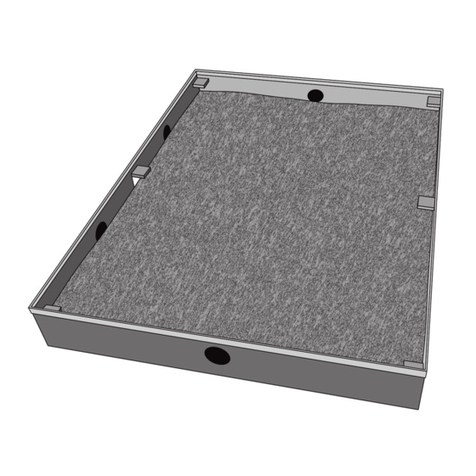

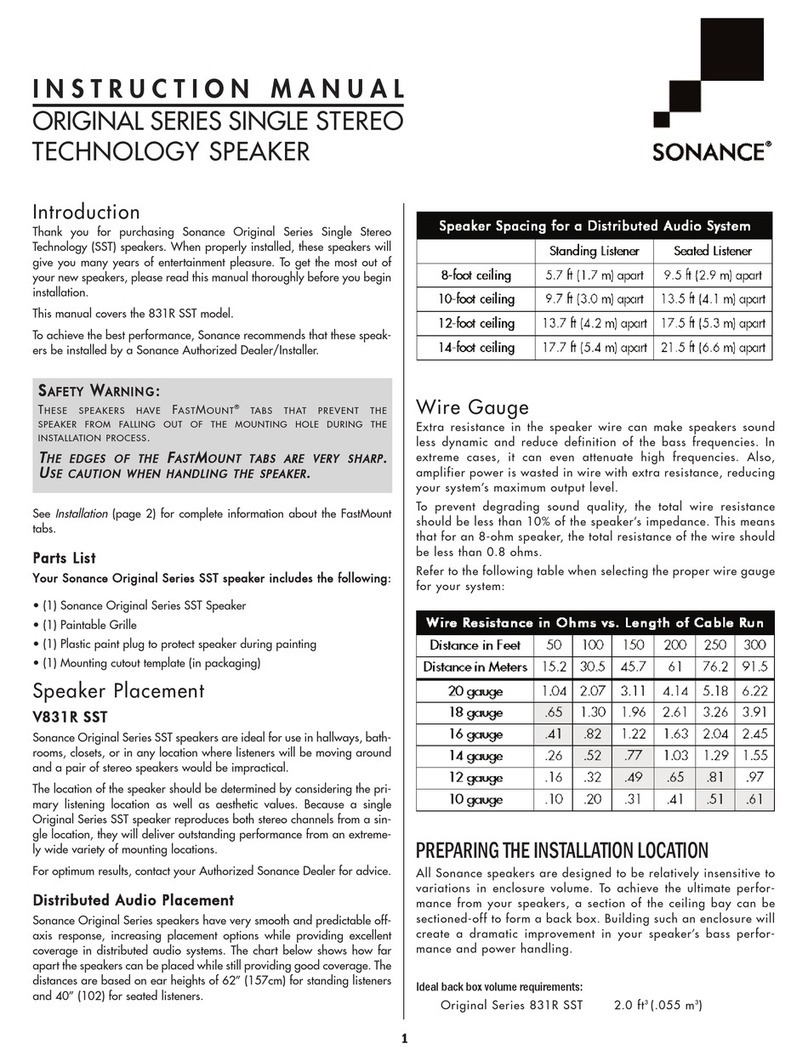

Cavity installation

05

Locate joist work

When you have chosen your speaker

locations, before cutting a hole in the

plasterboard it is important that you locate

the position of the wall studs. Ensure the

spacing between them is at least 350mm

(133/4”) for a portrait orientated speaker.

01

Create 455 x 350mm aperture

Using a sharp knife or pad saw, cut an

aperture with dimensions 455mm x 350mm

(18” x 14”) in your plasterboard wall or ceiling.

Ensure aperture is created between

supporting joists or stud work.

We strongly advise that joists are not cut to

make space for the backbox. Any activity of

this sort may well influence the structural

integrity of your property.

Important: Double check the size of the

aperture is 455mm x 350mm (18” x 14”) as

this is important further on into the

installation process.

02

02

Typically a new build or full refurbishment.

Uses fixing blocks (sold seperately)

Reference pages for correct retrofit alignment and plastering method: 14 + 15

Reference page for correct new build alignment and plastering method: 16

Reference pages for correct drywall alignment and plastering method: 20 + 2 1

sharp knife

pad saw

350mm

(minimum)

cut a small

hole in plasterboard

to check stud location

01

Preparing the wall/ceiling and fixing the product

SPACESAVER:

The supplied Spacesaver may be used to

show the position of the speaker pre-install

by securing it to the wall.

Secure the speaker cable to the Spacesaver

before any building electrical inspection.

See page 30 for full details.