Copyright 1998-2016 page 6 of 35

2.0 Safety

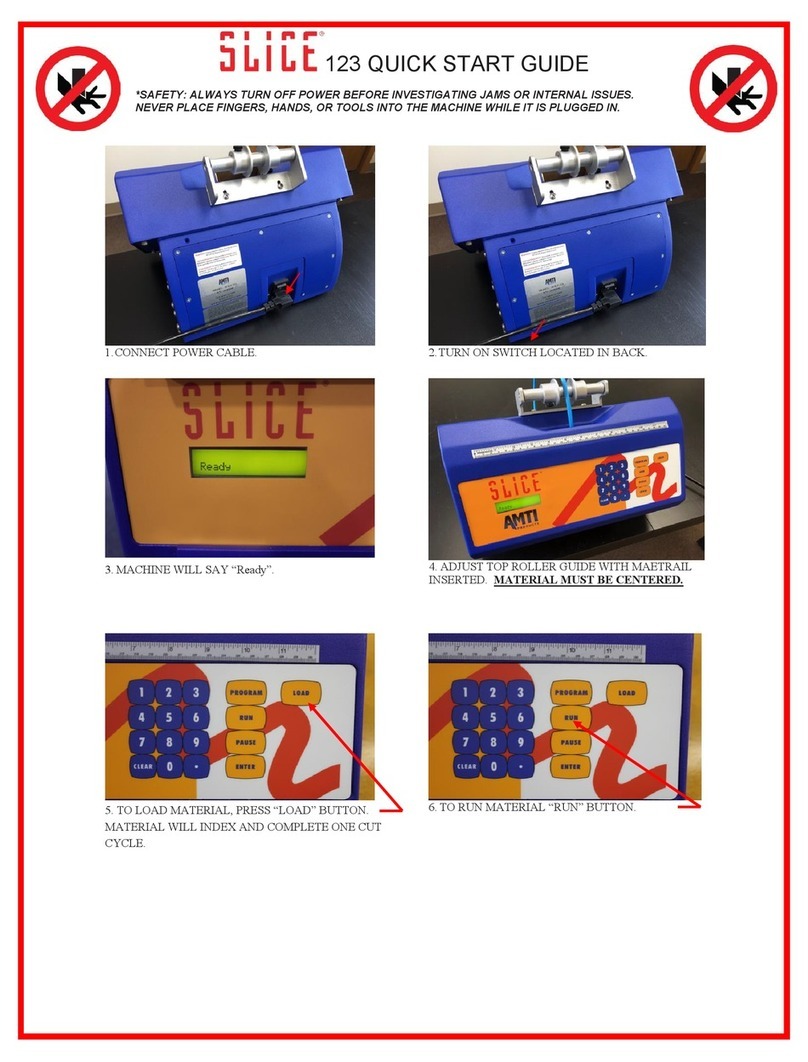

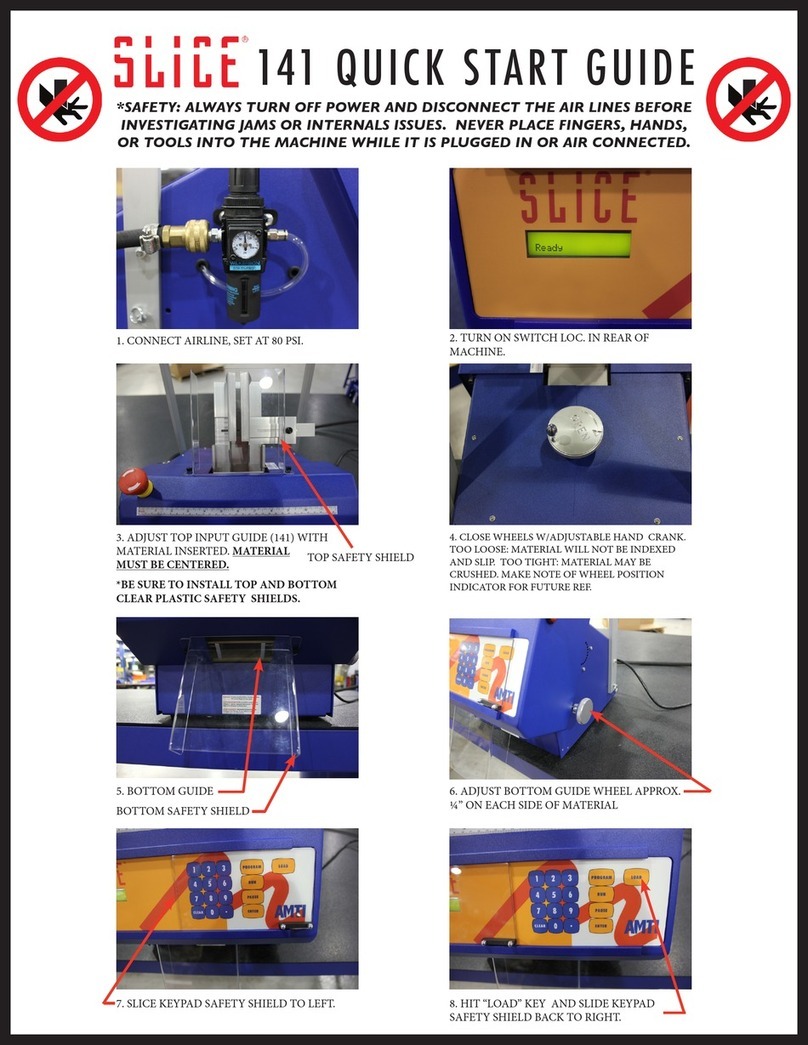

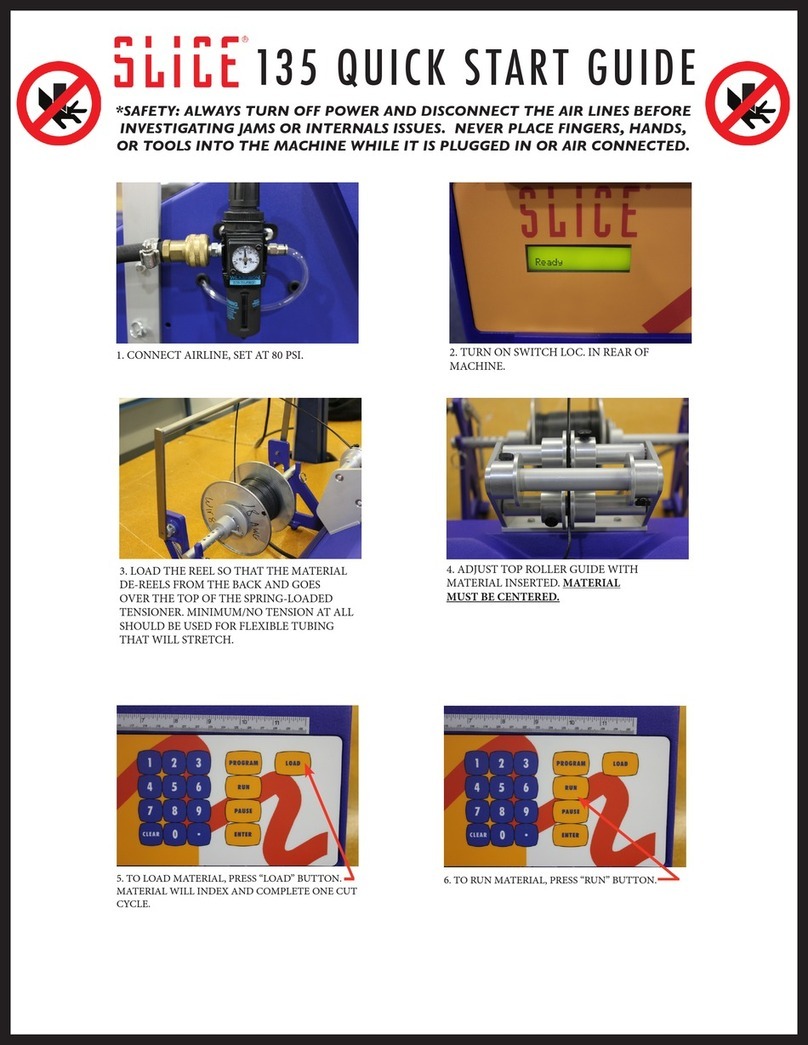

Always observe the following safety rules:

1. These sets of documentation are integral parts of the machines and

devices they were written for and must be heeded.

2. Always turn off power and disconnect the air lines before investigating

jams or internal issues.

3. Never place fingers, hands, or tools into the machine while it is plugged in.

4. Prior to starting the machine, check to see that all safety features are

attached and properly operating. The safety requirements are met only if the

safety features are operating properly.

5. Machine safety is only achieved when the materials being processed (wire,

tubing, etc.) are those specified in the technical data. Make sure the improper

use of materials is prevented!

6. Do not cut flammable, explosive, wet, etc. materials.

7. Do not operate outside standard environment requirements and use power

supply as recommended.

8. Only duly authorized and trained persons familiar with the safety features of

the machine are allowed to maintain and repair the machine. The machine can

be dangerous if operated improperly by untrained persons.

9. Machine safety is achieved only for operators. Persons working on the

machine must always take care that no other persons are endangered by the

input of a command.

10. If you have reason to believe the machine can no longer be operated

safely, you must take the system out of operation and safeguard it against

being unintentionally switched back on.

11. Observe the notes in these instructions as well as locally valid rules of

safety and accident prevention.