AMTI Products Slice 141 User manual

SLICE® Operating Instructions-SUP4302-R6118

Copyright 1998-2013page 1of 50

by

OPERATING INSTRUCTIONS

MODEL 141

READ CAREFULLY

BEFORE OPERATING YOURMACHINE

A Safety Note:

Your good manufacturing practices should insure that a written safety program is in place, which includes the

assessment of all processes that take place in house, for potential risks.

The employer response to this assessment is to establish specific instructions for the safe use of all machines,

safe use of certain chemicals, etc. in your work place.

For instance,any user of electrical machinery,SLICE®included, must be instructed that never, under any

circumstances,should amachine be left on while attempting to clear ajam ,if it should occur.

This written rule, along with other directives, should be translated into either atraining document that is

signed or work instruction that is also signed and dated by all operators and that ideally remains with the

equipment as a reminder of safe operation.

SLICE® Operating Instructions-SUP4302-R6118

Copyright 1998-2013page 2of 50

Published by:

AMTI

Phone: 847.588.7080

Email: [email protected]

Website: www.amtiproducts.com

The reproduction of these instructions or parts thereof, in whatever form, is prohibited

without the express, written permission of the publisher.

AMTI reserves the right to make technical changes in the system depicted and indicated

in these instructions if such changes are necessary to improve the machine.

©2013 by AMTI

SLICE® Operating Instructions-SUP4302-R6118

Copyright 1998-2013page 3of 50

Index

1.0 Product Description ............................................................................................... page 4

2.0Safety ..........................................................................................................

page 6

3.0 Operating Instructions ........................................................................................... page 7

4.0Machine Overview ..............................................................................................

page 10

5.0 Set Up ..........................................................................................................

page 13

6.0 Cut Material To Length Without Using AProgram................................................. page 17

7.0 Cut Material To Length Using AProgram (A Preprogrammed Batch) .................. page 19

8.0 How To Run An Existing Program .......................................................................... page 20

9.0HowToSetUpAndRunABatchSequence.........................................................

page 20

10.0 Batch SequencePause Feature........................................................................... page 21

11.0 Reprogramming The Unit..................................................................................... page 21

12.0ContactInformation..........................................................................................

page 26

13.0MaintenanceSection ........................................................................................

page 27

14.0 ExplodedAssembly View ..................................................................................... page 32

15.0 Trouble Shooting .................................................................................................. page 44

16.0FCCStatement ..................................................................................................

page 49

17.0 CE Declaration Of Conformity.............................................................................. page 50

SLICE® Operating Instructions-SUP4302-R6118

Copyright 1998-2013page 4of 50

1.0

Product Description

The SLICE® 141 is an automatic cutting machine intended to cut various materials to

length within the scope of the technical data. It is for industrial use.

1.1

System Description:

1. Opening aperture size 3” wide, adjustable up to 1.5” high

2. Adjustable guides to optimize the squareness of cut

3. “Stock Jam or Not Feeding” indicator

4. Standard SLICE® Keyboard

5. SLICE® software modified to sense cutter return stroke

6. Air filters and regulators, blade and die

7. Three drive wheels and tracking wheel to enhance pulling action

SLICE® Operating Instructions-SUP4302-R6118

Copyright 1998-2013page 5of 50

1.2 FUNCTION AND OPERATION

1. Operates as other models in the SLICE®series

2. Cutting blade force supplied by air cylinder, yielding a 360 pound cutting force

1.3 PERFORMANCE SPECIFICATIONS

1.

Cuts up to 10 gauge standard wire and varieties of hollow tubing including

convoluted tubing split/non-split that fits within its input aperture of 3” wide by 1.5”

high.

2.

Adjustable feed rate from 1” per second to 30” per second

3.

5,200 4” cuts per hour, 3,400 10” cuts per hour

4.

Machine Discrimination 0.5mm repeatability and accuracy is greatly dependent upon

material and material feeding conditions. Best accuracy to be expected is ± 1mm.

1.4

POWER AND AIRREQUIREMENTS

1. Electrical 115/230 volts at 50/60 hertz adequate

2. Air pressure to maintain 80 psi machine pressure

1.5 OPERATING CONDITIONS

Temperature 10˚ to 35˚ C

1.6

SYSTEM SIZE

Length: 15” Width: 16” Overall Height: 19” Housing Height: 13”

1.7

UNIT WEIGHT

55 pounds

Stainless steel, aluminum & hardened tool steel construction

1.8 MAX SOUND LEVELS

70DB

1.9

MATERIALS

The SLICE® 141 will cut most materials that will fit within the opening aperture 3” wide

by 1.5” high. Examples of material it will process:

1. Standard wire up to 10 GA.

2. Flat heat shrink, tubing,hose up to 3” wide max 1.5” high

3. Copper or plastic braided material up to 3” wide

4. Many other materials, please consult with sales representative or engineering

SLICE® Operating Instructions-SUP4302-R6118

Copyright 1998-2013page 6of 50

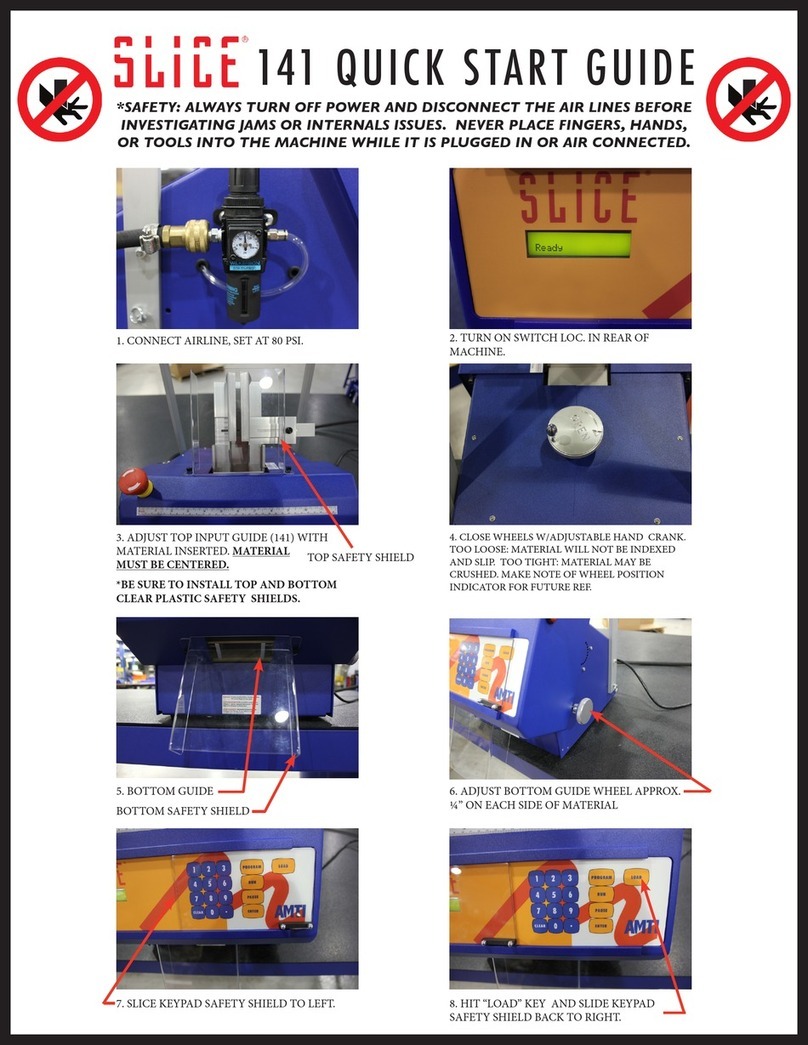

2.0 Safety

Always observe the following safety rules:

1. These sets of documentation are integral parts of the machines and devices they

were written for and must be heeded.

2. Always turn off power and disconnect the air lines before investigating jams or

internal issues.

3. Never place fingers, hands,or tools into the machine while it is plugged in or air

connected.

4. Prior to starting the machine, check to see that all safety features are attached and

properly operating. The safety requirements are met only if the safety features are

operating properly.

5. Machine safety is only achieved when the materials being processed (wire, tubing,

etc.) are those specified in the technical data. Make sure the improper use of materials

is prevented!

6. Do not cut flammable,explosive, wet, etc. materials.

7. Do not operate outside standard environment requirements and use power and air

supply as recommended.

8. Only duly authorized and trained persons familiar with the safety features of the

machine are allowed to maintain and repair the machine. The machine can be dangerous

if operated improperly by untrained persons.

9. Machine safety is achieved only for operators. Persons working on the machine must

always take care that no other persons are endangered by the input of a command.

10. If you have reason to believe the machine can no longer be operated safely, you

must take the system out of operation and safeguard it against being unintentionally

switched back on.

11. Observe the notes in these instructions as well as locally valid rules of safety and

accident prevention.

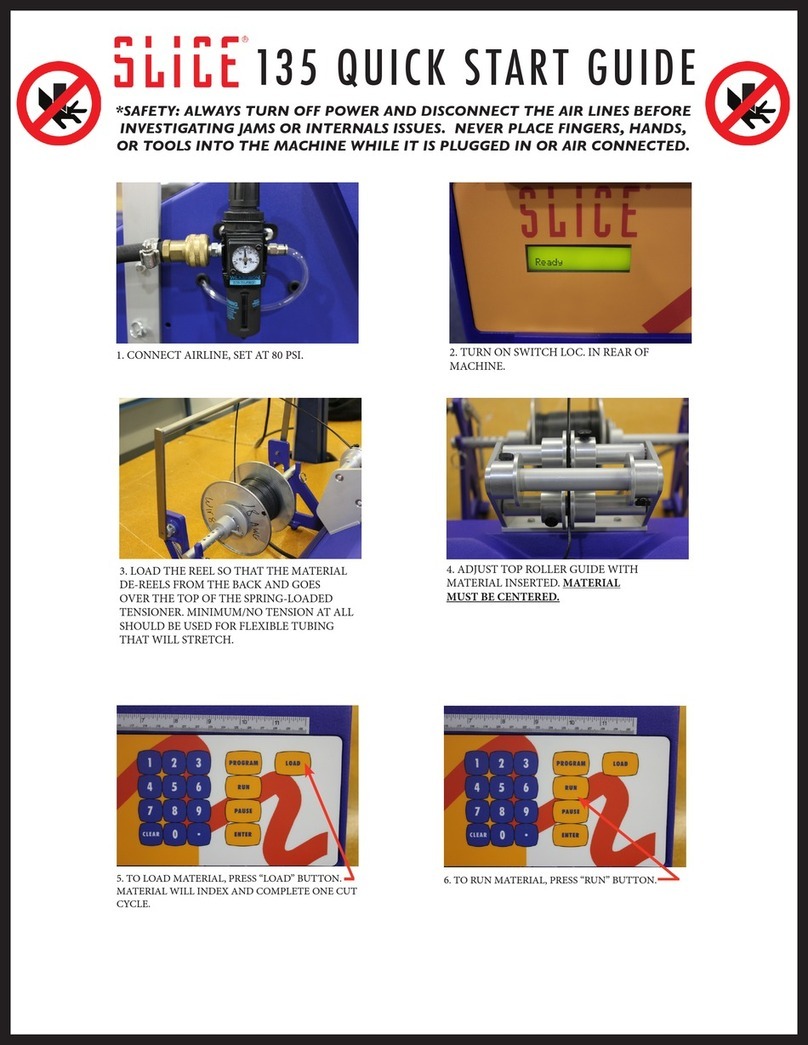

SLICE® Operating Instructions-SUP4302-R6118

Copyright 1998-2013page 7of 50

3.0

The Operating Instructions

These operating instructions are valid for the SLICE® 141, and are available in English

and Spanish. Other languages are available upon request.

These instructions contain complete information on the controls, handling, maintenance,

and setting procedures as well as all technical data. They also include a list of

accessories. These sets of documentation for the accessories are delivered along with

each accessory. Be careful not to mislay these sets of documentation when unpacking

and setting up accessories.

The operating instructions are an integral part of the SLICE® 141. Keep them within

reach so you have access to the information you need at all times.

Pay very close attention to the safety notes and directions. If you need additional sets of

documentation, please contact AMTI for more details.

Standard Uses

Cutting wire to length

Cutting hose to length

Cutting convoluted tubing split/non-split

Cutting flat cable to length

End-of-wire detection (SS wheels only)

Pay very close attention to the safety notes and directions.

If you need additional sets of documentation, please contact AMTI for more details.

SLICE® Operating Instructions-SUP4302-R6118

Copyright 1998-2013page 8of 50

3.1

Machine Identification

On the back of the machine you will find a nameplate with the following information:

Company Contact

Machine Type

Machine Serial Number

Voltage Version

Power Input

SLICE® Operating Instructions-SUP4302-R6118

Copyright 1998-2013page 9of 50

3.2

Personal Qualifications And Training

3.2.1

Personnel Qualifications

Machine Operator

The machine operator must be sufficiently familiar with the machine to be able to

operate it and its accessories and peripheral devices in production on his/her own

without difficulty. This requires that the operator be well educated in the technology

involved and be knowledgeable of the software for operating the machine.

Service Technician

The service technician should have an extensive knowledge of the machine. Apart

from machine operations, he/she must be able to locate errors and take suitable steps

to remedy them. A service technician must be able to maintain the machine correctly

so as to increase its service life and availability. His/her mastery of the software should

enable the machine to be used to the maximum effect in production.

For this work, the service technician must have wire processing experience. He/

she must also have completed training in mechanics or electronics and have a sound

knowledge of the machine.

3.2.2

Training

All personnel that are using the SLICE® equipment should be trained on its proper use

and safety needed when operating this equipment.

SLICE® Operating Instructions-SUP4302-R6118

Copyright 1998-2013page 10 of 50

7.

4.0 Machine Overview (front)

1. Adjustable Material Guide

2. Roller Guide

3. Function Buttons

4. Keypad

5. LCD Readout

6. Activation Push Buttons (both sides)

7. Keypad Safety Shield

8. Adjustable Top Input Guide

9. Bottom Output Guide

10. Bottom Guide Adjustment Wheel

11. Emergency Stop Button

2.

1. 8.

11.

5.

4.

9. 3.

6.

10.

Other manuals for Slice 141

1

Table of contents

Other AMTI Products Cutter manuals

Popular Cutter manuals by other brands

Bosch

Bosch POF 1400 ACE Original instructions

SignWarehouse.com

SignWarehouse.com Bobcat BA-60 user manual

Makita

Makita 4112HS instruction manual

GEISMAR STUMEC

GEISMAR STUMEC MTZ 350S manual

Hitachi

Hitachi CM 4SB2 Safety instructions and instruction manual

Dexter Laundry

Dexter Laundry 800ETC1-20030.1 instruction manual