SLICE® Operating Instructions-SUP4300-R71113

Copyright 1998-2013 page 5 of 44

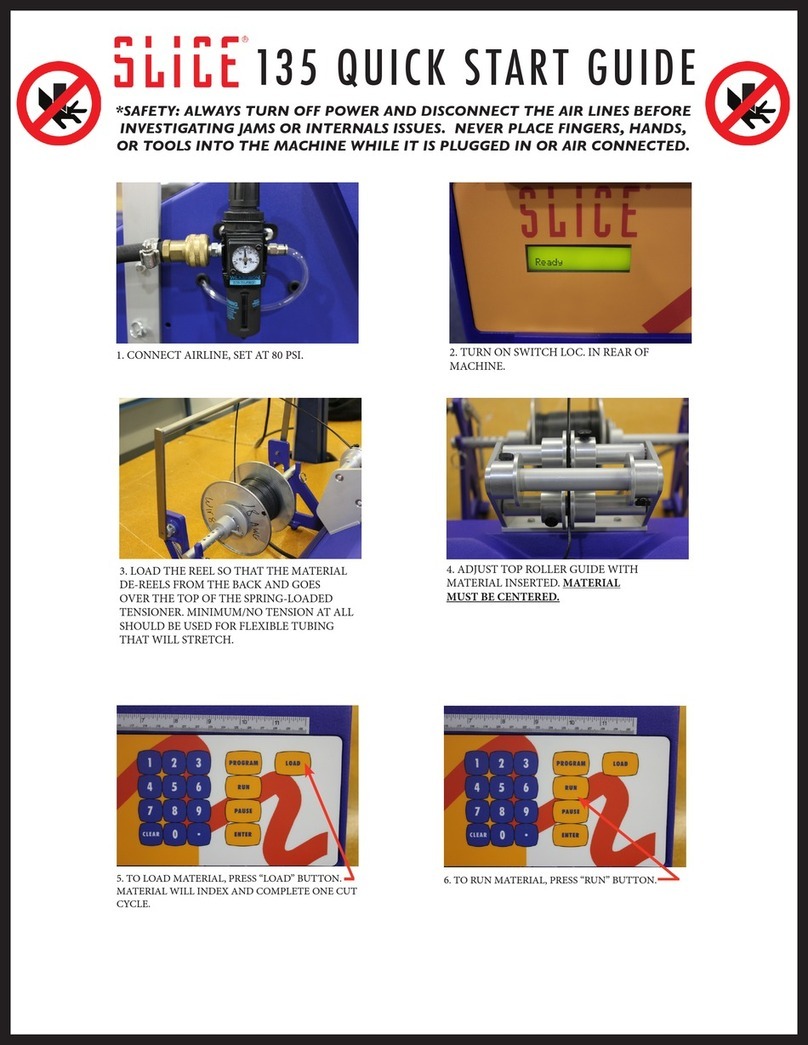

1.2 FUNCTION AND OPERATION

1. Operates as other models in the SLICE® series.

2. Cutting blade force supplied by air cylinder, yielding a 360 pound cutting force.

1.3 PERFORMANCE SPECIFICATIONS

1. Cuts up to 12 gauge standard wire and varieties of hollow tubing that ts within its

input aperture of 1/4” X 3”.

2. Adjustable feed rate from 1” per second to 30” per second.

3. 5,200 4” cuts per hour, 3,400 10” cuts per hour.

4. Machine discrimination 0.5mm repeatability and accuracy is greatly dependent upon

material and material feeding conditions. Best accuracy to be expected is ± 1mm.

1.4 POWER AND AIR REQUIREMENTS

1. Electric 115/230 volts at 50/60 hertz adequate

2. Air pressure to maintain 80 psi machine pressure

1.5 OPERATING CONDITIONS

Temperature 10˚ to 35˚ C

1.6 SYSTEM SIZE

Length: 15” Width: 16” Overall Height: 19” Housing Height: 13”

1.7 UNIT WEIGHT

45 pounds

Stainless steel, aluminum & hardened tool steel construction

1.8 MAX SOUND LEVELS

74 DB

1.9 MATERIALS

The SLICE® 135 will cut most materials that will t within die size of 1/4” diameter x

3” wide at. Material needs to be under 1/4” diameter or thick as it comes off the roll.

Contact AMTI to see if material is a good t for this machine.

Examples of material it will process:

1. Standard wire up to 12 GA

2. Rubber tubing or hose under 1/4” diameter thick

3. Flat heat shrink up to 3” wide or 1/4” in diameter thick

4. Copper or plastic braided material up to 3” wide

5. Many other materials, please consult with sales representative or engineering