AND AD-4212F Series User manual

AD-4212F SERIES

AD-4212F-6203D

AD-4212F-10202

AD-4212F-22001

Production Weighing Unit

1WMPD4004727A

This Manual and Marks Herein

All safety messages are identified by the following: “CAUTION” or “NOTICE” of ANSI Z535.4 (American

National Standard Institute: Product Safety Signs and Labels).

The meanings are as follows:

Meaning of warning signs

Indicates a hazardous situation which, if not avoided, could result in minor or moderate

injury.

Indicates procedures not related to physical injury.

Meaning of graphic symbols

This is a safety alert symbol.

The symbol indicates what you must not do (prohibited).

Specific prohibitions are indicated in writing or by pictures inside or near the .

The figure on the left indicates "No impact".

Others

Note

Describes "when it is easy to mishandle" and "general advice when using this product".

About This Manual

(1) No part of this manual may be reprinted, copied, modified, or translated to another language without the

prior written consent of A&D Company, Limited (A&D).

(2) The contents of this manual are subject to change without notice.

(3) Please contact A&D if you notice any uncertainty, errors, omissions, etc. in this manual.

(4) A&D bears no liability for any loss or lost profits due to the operation of this product, and for direct, indirect,

special, or consequential damages resulting from any defect in this product or this manual, even if advised

of the possibility of such damage. Furthermore, A&D assumes no liability for claims of rights from third

parties. Concurrently, A&D assumes no liability whatsoever for software or data losses.

© 2023 A&D Company, Limited

Microsoft®, Windows®, Word®, and Excel®are trademarks of the Microsoft group of companies.

Other product names and company names mentioned in this manual are trademarks or registered

trademarks of their respective companies in Japan or other countries and regions.

CAUTION

NOTICE

3

Contents

1. Introduction.................................................................................................................................... 5

1-1. Features ....................................................................................................................................... 5

1-2. Compliance .................................................................................................................................. 8

2. Part Names, Installation and Precautions................................................................................. 10

2-1. Assembly and installation........................................................................................................ 11

2-1-1. Mass of exclusive weighing pans created by customers.................................................. 12

2-1-2. Attaching the weighing unit directly on the mounting base ............................................. 14

2-2. Precautions before use (Installation considerations and preparation)............................... 15

2-3. Precautions when incorporating into a system ..................................................................... 16

2-4. Cautions during use (for more accurate weighing)............................................................... 20

2-5. Cautions after use..................................................................................................................... 20

2-6. Power supply............................................................................................................................. 20

2-7. Indicator lights........................................................................................................................... 21

3. Operation of WinCT-AD4212F .................................................................................................... 22

3-1. Sensitivity adjustment .............................................................................................................. 26

3-1-1. Sensitivity adjustment method............................................................................................. 27

3-1-2. Changing weight value.......................................................................................................... 29

3-2. Self-check function ................................................................................................................... 31

3-2-1. How to use the self-check function of WinCT-AD4212F.................................................... 31

3-3. Filter settings............................................................................................................................. 34

3-3-1. Standard settings .................................................................................................................. 34

3-3-2. Customize............................................................................................................................... 35

3-4. Changing the baud rate using WinCT-AD4212F .................................................................... 49

3-5. Multiple connections (RS-485)................................................................................................. 50

4. Smart Range Function ................................................................................................................ 52

5. Impact Shock Detection Function.............................................................................................. 53

5-1. Recording impact history......................................................................................................... 53

5-2. Outputting impact history ........................................................................................................ 54

6. Communication Specifications .................................................................................................. 55

6-1. RS-232C...................................................................................................................................... 55

6-1-1. RS-232C specification ........................................................................................................... 55

6-1-2. AX-KO3590-1000 pin position............................................................................................... 56

6-2. RS-485 ........................................................................................................................................ 56

6-2-1. RS-485 specifications............................................................................................................ 57

6-2-2. Pin position when using AX-KO7522-500 ........................................................................... 57

6-2-3. Changing device address and terminating resistor settings............................................ 58

6-2-4. Checking device address...................................................................................................... 58

6-2-5. How to install the RS-485 interface for daisy chain ........................................................... 59

6-2-6. Daisy chain connection (communication cable connection)............................................ 60

6-2-7. Daisy chain connection (AC adapter connection).............................................................. 61

6-3. Data output format .................................................................................................................... 62

6-4. Command................................................................................................................................... 63

6-4-1. AK code and error code....................................................................................................... 65

7. Maintenance ................................................................................................................................. 71

4

7-1. Care ............................................................................................................................................ 71

8. Troubleshooting .......................................................................................................................... 72

8-1. Checking the weighing unit performance and environment ................................................ 72

8-2. Asking for repair ....................................................................................................................... 73

9. Specifications .............................................................................................................................. 74

9-1. External dimensions ................................................................................................................. 75

10. Peripherals (sold separately) ..................................................................................................... 76

10-1. Accessories ............................................................................................................................... 76

10-2. Options....................................................................................................................................... 76

11. Terms ............................................................................................................................................ 78

5

1. Introduction

Thank you for purchasing an A&D’s AD-4212F Production Weighing Unit.

This instruction manual describes how the AD-4212F series (the weighing unit) works. Please read this manual

carefully before using the weighing unit to understand and get the most out of it.

1-1. Features

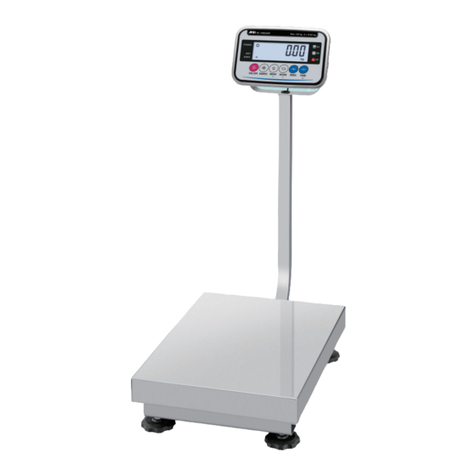

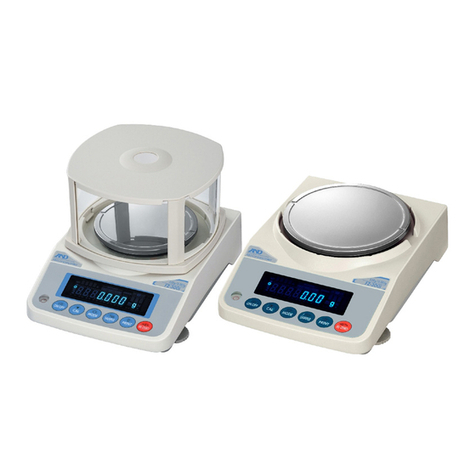

The compact weighing unit has a width of only 80 mm, making it ideal for incorporating into production

lines.

The Super Hybrid Sensor (SHS) is used to provide high resolution and fast response time.

Model

Weighing

capacity

Readability Stabilization time*1

AD-4212F-6203D

510 g*2

0.001 g

1.3 seconds

6200 g

0.01 g

1.0 second

AD-4212F-10202 10200 g 0.01 g

0.5 second (0 to 300 g),

1.0 second (300 to 10200 g)

AD-4212F-22001 22000 g 0.1 g

0.5 second (0 to 300 g),

1.0 second (300 to 22000 g)

*1 When the stability band width is set to ±3 digits and FAST is selected in a good environment.

*2 Smart range (Refer to "4. Smart Range Function".)

The weighing unit outputs digital data directly via an RS-232C or RS-485 interface. That enables it to be

connected directly to a personal computer (PC) or programmable logic controller (PLC).

Installing an RS-485 interface for daisy chain (accessory AD4212F-29, sold separately) on the weighing

unit allows commands to be exchanged between daisy-chained units via RS-485 communication by

changing the device address of each weight unit. (Up to 31 units.)

Dustproof and waterproof (IP65 compliant).

The WinCT-AD4212F data communication software makes it easy to check weighing values on a PC

running Windows. In addition, filter settings can be easily applied as needed for the operating environment,

required response speed or desired accuracy, by being graphically simulated.

Connecting to an AD-8922A remote controller (sold separately) enables reading of the weighing data of

the weighing unit and manual re-zero and sensitivity adjustment operations. In addition, the options for

BCD output, comparator output, and analog output operations are available for the AD-8922A.

Connecting to an AD-8923-BCD or AD-8923-CC remote controller (sold separately) enables reading of

the weighing data of the weighing unit and manual re-zero and sensitivity adjustment operations. In

addition, the AD-8923-BCD is capable of BCD output, and AD-8923-CC can use CC-Link interface.

Note

CC-Link is a high-speed field network allowing simultaneous handling of both control and

information.

By connecting an AD-8551R Modbus RTU converter (sold separately), RS-232C output can be converted

into RS-485 communication for Modbus RTU.

By connecting an AD-8552EIP EtherNet/IP converter (sold separately), RS-232C output can be converted

into EtherNet/IP communication.

6

Example 1 (Connecting to a PC or remote controller AD-8922A)

--------------------------------------------------------------------------------------------------------------------------------------------

--------------------------------------------------------------------------------------------------------------------------------------------

USB converter

(accessory: AX-USB-9P-EX)

The weighing unit

Data communication software

“WinCT-AD4212F”

USB port

PC

RS-232C cable

(accessory: AX-KO3590-1000)

The weighing unit

RS-232C cable

(accessory: AX-KO3590-1000)

AD-8922A

Data communication software

“WinCT”

USB port

USB converter

(accessory: AX-USB-9P-EX)

Communication cable

AX-KO1786-200

PC

7

Example 2 (Connecting to a PLC)

--------------------------------------------------------------------------------------------------------------------------------------------

*1 To connect more than one weighing unit in a daisy chain, an RS-485 interface for daisy chain (accessory

AD4212F-29, sold separately) is required for each unit.

Refer to “6-2. RS-485” for installation of the RS-485 interface for daisy chain, daisy-chaining connection,

and AC adapter connection.

--------------------------------------------------------------------------------------------------------------------------------------------

*2 Please select from below when ordering an AD-8922A-01:

AX-KO3705-200 2 m

AX-KO3705-500 5 m

AX-KO3705-1000 10 m

--------------------------------------------------------------------------------------------------------------------------------------------

The weighing unit

PLC

RS-232C cable

(accessory: AX-KO3590-1000)

RS-485 cable for daisy chain

(accessory: AX-KO7622-200)

PLC

Individual units*1

RS-485 cable (discrete wire)

(accessory: AX-KO7522-500)

The weighing unit

AD-8922A

AD-8922A-01 connection cable*2

PLC

BCD cable

(Please prepare this cable yourself.)

BCD input

BCD output

(option: AD-8922A-01)

RS-485 interface for daisy chain

(accessory: AD4212F-29)

8

--------------------------------------------------------------------------------------------------------------------------------------------

--------------------------------------------------------------------------------------------------------------------------------------------

--------------------------------------------------------------------------------------------------------------------------------------------

PLC

AD-8923-CC

RS-232C cable

(accessory: AX-KO3590-1000)

CC-Link

network

Other remote station, etc.

The weighing unit

The weighing unit

AD-8551R

PLC

RS-485 cable

(

Please prepare this cable

yourself.)

RS-232C cable

(accessory: AX-KO3590-1000)

Other device, etc.

The weighing unit

PLC

RS-232C cable

(accessory: AX-KO3590-1000)

AD-8552EIP

Other device, etc.

LAN cables

9

1-2. Compliance

Compliance with FCC rules

Please note that this equipment generates, uses and can radiate radio frequency energy. This equipment has

been tested and has been found to comply with the limits of Class A digital devices pursuant to Part 15 of FCC

rules. These rules are designed to provide reasonable protection against interference when equipment is

operated in a commercial environment. If this unit is operated in a residential area, it may cause some

interference and under these circumstances the user would be required to take, at his own expense, whatever

measures are necessary to eliminate the interference. (FCC = Federal Communications Commission in the

U.S.A.)

10

2. Part Names, Installation and Precautions

The AD-4212F (the weighing unit) is a precision instrument. Unpack the product carefully. Keep the

packing material for use in transporting the weighing unit in the future for repairs.

When unpacking, see the illustration below to confirm that everything is included.

No.

Name

1

Weighing pan

2

Screw for fixing pan support (Pan head screw: M5 screws x 10)

3

Pan support

4

Pan support boss

5

Main body

6

Rear of the main body

7

AC adapter jack

8

AC adapter plug

9

RS-232C output connector*1

10

Grounding terminal*3

11

Indicator lights

12

AC adapter*2

13

Positions of AC adapter ID labels

14

AC adapter ID labels

15

Serial number

*1 The connection cable is sold separately. (Refer to " 10-1. Accessories".)

*2 Please confirm that the AC adapter type is correct for your local voltage and receptacle type.

*3 When the weighing unit is incorporated into a system, be sure to ground the weighing unit using the

ground terminal.

Use the specified dedicated AC adapter for the weighing unit.

Use the included AC adapter, and do not connect an AC adapter that is not compatible.

If you use the wrong AC adapter, the weighing unit and other devices may not work properly.

NOTICE

1

2

3

4

5

6

9

7

8

10

11

12

14

13

15

11

2-1. Assembly and installation

1. Consider the cautions described later regarding the place to install the weighing unit.

2. Set the pan support and weighing pan while referring to "2. Part Names, Installation and Precautions".

3. Securely insert the accessory RS-232C cable into the connection jack on the back of the weighing unit.

(When communicating via RS-485, replace the rear panel with the accessory RS-485 interface and use

the accessory RS-485 cable. Refer to "6-2-5. How to install the RS-485 interface for daisy chain" for how

to install the RS- 485 interface.)

How to disconnect the cable from the weighing unit

Slide the connector sleeve (the part marked with an arrow) to unlock the connector, and then pull

out the connector.

Slide to unlock Unlocked

4. Confirm that the AC adapter type is correct for the local voltage and power receptacle type.

5. Plug the AC adapter plug into the AC adapter jack located on the rear of the weighing unit and plug the

AC adapter into the electrical outlet. Warm up the weighing unit for at least 30 minutes with nothing on

the weighing pan.

6. Set the pan unit and I/O unit to adapt to the peripheral system. Set the following for the I/O unit.

・RS-232C settings (Refer to "6. Communication Specifications" for details.)

Set the weighing speed (response characteristics) to adapt to the ambient conditions. (Refer to " 3-3.

Filter settings " for details.)

Start up the PC before connecting to the weighing unit.

7. After installation, it is advisable to adjust the sensitivity using a weight.

(Refer to " 3-1. Sensitivity adjustment " for details.)

8. If the provided weighing pan is removed, exclusive weighing pans created by customers can be

attached to the four screw holes (M4 screw x pitch 0.7 mm) on the pan support.

NOTICE

Connect to a PC to check the

performance of the weighing unit

with “WinCT-AD4212F”.

Attach the arrow ()

side up.

12

2-1-1. Mass of exclusive weighing pans created by customers

The weighing pan of the AD-4212F is removable, and customers can create their own exclusive weighing pans

as a jig.

When designing your own exclusive jig weighing pan, note that the mass must fall within the ranges shown in

the table below. For the mass ranges to be weighed, refer to the figures below the table.

Model Mass (g) of exclusive weighing pan

AD-4212F-6203D 40 to 6030

AD-4212F-10202 40 to 10030

AD-4212F-22001 40 to 21830

AD-4212F-6203D AD-4212F-10202 AD-4212F-22001

Notes

For use in a range other than those shown above, contact your local A&D dealer.

To avoid the effects of static electricity or magnetism, use materials other than resin or

magnetic materials when designing a weighing pan.

When an exclusive weighing pan is used, the zero point may be shifted greatly right after the

AC adapter is plugged in. Perform re-zero before weighing to cancel the amount of zero drift

as necessary.

Mass of

exclusive

weighing

pan

Mass range

to be

weighed

6200 g

40 g

6030 g

210 g

10200 g

40 g

210 g

10030 g

22000 g

21830 g

210 g

40 g

Mass range

to be

weighed

Mass range

to be

weighed

Mass of

exclusive

weighing

pan

Mass of

exclusive

weighing

pan

13

Precautions when not weighing at the center of the provided weighing pan

To use your exclusive jig weighing pan instead of weighing at the center of the provided weighing pan, attach

the jig so that the total moment of the jig and the object to be weighed is less than the value specified in the

table below.

Allowable eccentric load for each model (Nm)

Model

Allowable eccentric load

AD-4212F-6203D

1 Nm or less

AD-4212F-10202

1 Nm or less

AD-4212F-22001

1 Nm or less

AD-4212F-6203D / 10202 / 22001

Example where the total moment of the jig and the object to be weighed is 1 Nm or less:

Notes

The values mentioned above are for reference and may be different from actual specifications.

Since there is no built-in overload protection mechanism, do not overload.

When designing jigs and the like, consider that the pan unit may sink slightly if a heavy object

is placed on it.

1000 g × 0.1 m

1000 g

0.1 m

14

2-1-2. Attaching the weighing unit directly on the mounting base

For stable weighing, fix the weighing unit to the installation platform with screws.

How to attach

Use the screw holes on the weighing unit to fix it.

When screwing from the top: M6 screw × 4

When screwing from the bottom:

M8, P1.25 screw × 4

Notes

Please prepare four screws for securing the

weighing unit to the platform.

For the positions of the holes, refer to “9-1.

External dimensions”.

Depending on the conditions in which it is

installed, the levelness of the weighing unit may

not be adjustable. In such cases, try adjusting

the levelness by inserting a shim between the

bottom surface of the weighing unit and the

securing surface or by using two nuts. Even if

the levelness cannot be adjusted, performing

sensitivity adjustment before use in the

conditions in which the unit is installed will

prevent performance problems from occurring.

Screw holes

M6 screw × 4

M8 × P1.25 screw × 4

15

2-2. Precautions before use (Installation considerations and

preparation)

Prepare the following conditions in order to bring out the full performance of the weighing unit:

About dustproof / waterproof performance

・The dustproof and waterproof level of the weighing unit is equivalent to IP65, and its second digit, “5”,

corresponds to "having no harmful influence by receiving direct jet of water". Washing with strong water

pressure or submersion in water may cause water to enter the balance and cause a malfunction.

・When installing and using the weighing unit under conditions requiring dustproof and waterproof

performance, make sure that the AC adapter plug is fully inserted into the AC adapter jack and that the

RS-232C cable or RS-485 cable is attached.

・When not using the AC adapter or the RS-232C cable, keep the rubber caps of the packing sections

closed.

Rear of the weighing unit

The ideal installation conditions are a stable environment of 20 °C±2 °C and humidity of 45 to 60 %RH.

Use in an environment with as little dust and vibration as possible.

In a building, places near the walls rather than the central part of a room, and places on the first floor (i.e.

the ground floor) rather than the upper floors, are more suitable for weighing operations as they are less

prone to vibration.

Do not install the weighing unit near heating, ventilation, or air conditioning units and the like.

Avoid locations in direct sunlight.

Install the weighing unit away from equipment which produces magnetic fields.

Be sure to warm up the weighing unit before use for at least 30 minutes (with the AC adapter connected

to the power supply).

When the weighing unit is installed for the first time or has been moved, adjust the sensitivity before use

to ensure accurate weighing. Perform sensitivity adjustment regularly to maintain accuracy. (Refer to "3-

1. Sensitivity adjustment" for details.)

Do not install the weighing unit where flammable or corrosive gas is present.

CAUTION

AC adapter plug

Indicator lights

AC adapter jack

Ground terminal

Attach the arrow ()

side up.

RS-232C cable

Rubber caps

16

2-3. Precautions when incorporating into a system

This weighing unit is a high-precision electromagnetic balance. When it is incorporated into a system, errors

such as unstable weighing values may occur due to static electricity, vibration, sample temperature and

magnetism of the materials weighed or used for the devices near the weighing unit.

When using the weighing unit as part of a system, take the following precautions:

Notes

When fixing the weighing pan to the pan support boss, be careful not to apply excessive

rotational force or pressing force.

Do not apply force such as pulling up the pan support boss or applying force from the side.

Do not apply shock to the weighing pan.

Be sure to ground the weighing unit.

Keep the power supply line and signal line away from lines that carry large currents, such as

the power supply for drive equipment.

Errors due to static charge and countermeasures against those

[Phenomenon]

When the ambient humidity is less than 45% RH, insulators such as plastic or glass are prone to static

electricity. When charged material comes close to the weighing unit, a pulling force is generated by static

induction between the charged material and the weighing pan. This causes unstable weighing data.

To prevent a malfunction of the weighing unit due to a discharge generated by charged material when it

comes close to the weighing unit, be sure to ground the weighing unit.

It is advisable to use a humidifier or the AD-1683 static eliminator because static electricity generated by

static induction will not be canceled by grounding.

[Countermeasures]

The countermeasures explained below using plastic as an example can also be used for glass.

●When the sample or workpiece is plastic (especially films)

(1) Use a static eliminator with no fan (no breeze is produced) such

as the AD-1683 to remove static electricity.

(2) Place the sample or workpiece in a metal or other conductive

container to enclose it before weighing it.

The pulling force

causes an

unstable weighing

value.

A pulling force

generated

between the

charged sample

and the weighing

unit causes an

unstable

weighing value.

Charged plastic breeze break

Charged sample

Charged material

Metal case

Grounding

17

●When the sample is powder

When the weighing unit is used in combination with a feeder for batch weighing of powdery samples,

samples may be charged by rubbing sample particles against each other.

Use a static eliminator such as the AD-1683 and perform weighing while removing static electricity.

●When the sample container is made of material that is prone to static electricity (such as

plastic)

(1) Cover the outside of the container with a metal such as aluminum foil.

(2) Apply an anti-static agent onto the container.

●When making devices for blocking air current (breeze breaks) using plastic

Apply antistatic agent or use conductive acrylic resin, etc. to prevent static buildup.

●When plastic exists in the weighing unit installation site

If the plastic is electrically charged, it may attract the weighing pan or the sample or workpiece,

resulting in unstable weighing data.

(1) Cover the plastic with a grounded conductive material.

(2) Apply an anti-static agent onto the plastic.

●When an operator is static charged

In the winter when temperatures are low, the operator's clothing is more likely to be electrically charged,

and the weighing data may become unstable when the operator approaches the weighing unit. Take

measures against static electricity, such as wearing an antistatic wrist strap.

Errors due to airflow and countermeasures against those

●Effects of airflow

Weighing data may become unstable due to air currents

in the following locations: (1) near the outlets of heating,

ventilation, or air conditioning units, (2) near entrances or

exits, and (3) near corridors, etc.

Even airflow so weak that it is undetectable by humans

can cause the weighing value of the weighing unit to

become unstable.

Weighing operations in such locations should be avoided

if possible.

If weighing operations in such locations cannot be

avoided, take measures such as installing breeze breaks

while referring to "Errors due to static charge and

countermeasures against those".

Weighing data

becomes

unstable due

to air currents.

18

●Effects of heat and convection

・Weighing errors may occur if there is a difference between the

ambient temperature and temperature of the sample (and the

container). For example, when the room temperature is 20 °C,

convection occurs around a flask that is 40 °C and the balance

displays a value lighter than the actual weight. Before weighing

the sample and the container, try to acclimatize them to the

ambient temperature.

・The same phenomenon as above will occur if the sample is held

directly by hand, as the temperature of the sample rises due to

body heat. Do not hold it by hand; rather, use tweezers or the

like to manipulate it.

・Locations exposed to direct sunlight, such as near a window, may cause rapid temperature

changes and convection currents. Take measures such as shielding from heat or changing the

location.

Errors due to vibration and countermeasures against those

Weighing data may become unstable on windy days or after an earthquake in the following locations:

(1) weak ground, (2) floors higher than the first floor, (3) near the center of a room, etc. with the pillars

spaced wide apart, (4) earthquake-resistant structures, and (5) near tall buildings.

Especially in cases (4) and (5), continuous low-frequency vibration caused by strong winds or an

earthquake may persist and cause the weighing data to become unstable for a long period of time.

Errors due to moving the weighing unit

The performance of the weighing unit is guaranteed when it is used in a stationary condition.

If the weighing unit is incorporated into a system that moves the weighing unit, you must carefully

perform checks in advance while paying attention to the following:

・If the weighing unit is moved, it may be damaged by impact shocks.

In addition, the weighing value will be unstable immediately after the weighing unit is moved.

Avoid sudden movements, stops, or impact shocks, and provide a sufficient waiting time for the

weighing value to stabilize when acquiring weighing data.

・The moving device should have a structure where the weighing unit can be kept level.

If the level is shifted, the zero point or sensitivity will be shifted, so perform re-zero operation or

sensitivity adjustment.

・In order to avoid the influence of vibration, the moving platform should have a structure not easily

susceptible to vibration by means such as reducing the play of moving parts.

40 °C

20 °C

Convection

19

Errors due to other causes and countermeasures against those

●Effects of changes in temperature or humidity

Sudden environmental changes can cause convection or moisture absorption / release, and such

factors may cause the display of the weighing unit to become unstable.

Avoid sudden changes in temperature or humidity as much as possible.

It is advisable to use air conditioners, humidifiers, and the like to control the temperature and humidity.

●Influence of magnetic materials

Influence of magnetism may cause weighing errors.

To perform weighing of magnetic materials (iron, magnets, etc.), measurement errors must be

considered and checked before weighing by means such as placing a non-magnetic material

(aluminum, brass, etc.) between the sample and the weighing unit and keeping away from the

weighing unit.

20

2-4. Cautions during use (for more accurate weighing)

For accurate weighing, please pay attention to the following points.

To minimize the affect by electrical noises, ground the weighing unit

and the optional display unit.

When placing a sample on the weighing pan, do not drop it, or do not

place a sample greater than the weighing capacity of the weighing

unit. Place the sample in the center of the weighing pan to minimize

corner-load errors.

To prevent possible errors, use a command to re-zero, or calculate

the weighing data based on the difference before and after weighing.

The measurement results contain errors due to air buoyancy. The

buoyancy of air varies depending on the sample volume, atmospheric

pressure, temperature, and humidity.

Although the weighing unit is dustproof and waterproof complying with IP65, be sure to clean and control

the weighing pan and the area around the pan when weighing powders, fluids, or metal pieces.

2-5. Cautions after use

Avoid mechanical shock to the weighing unit.

Adjust the sensitivity of the weighing unit regularly using a weight.

Do not disassemble the weighing unit. Contact your local A&D dealer if the weighing unit needs service

or repair.

Do not use organic solvents to clean the weighing unit. Clean the weighing unit with a lint free cloth that

is moistened with warm water and a mild detergent.

Prevent foreign substances such as powder and liquid from entering the weighing unit.

2-6. Power supply

The weighing unit is constantly provided with power as long as the AC adapter is connected.

The weighing unit is not adversely affected in this state. It is advisable to always keep the weighing unit in this

state for accurate weighing.

This manual suits for next models

3

Table of contents

Other AND Scale manuals

AND

AND PREMIUM UC-352CNBLE User manual

AND

AND HT-300CL User manual

AND

AND GX-M Series User manual

AND

AND BA-TE Series User manual

AND

AND PLUSCONNECT UC-350CNBLE User manual

AND

AND UC-321 User manual

AND

AND HL-200i User manual

AND

AND GX-L Series User manual

AND

AND UC-352BLE User manual

AND

AND SJ-WP Series User manual