1. BRIEF INSTRUCTION

1.1 MCT series welding machine is the latest multi-purpose machine developed by our company. It

is suitable for all kinds of metal cutting machines, argon arc welding and manual arc welding. Its

biggest feature is that it can cut stainless steel, alloy steel, carbon steel, and other non-ferrous

metals with cutting function, or it can weld stainless steel and carbon steel products with DC

function. For example: for the welding of scooters, bicycles and other products.

1.2 MCT series welding machine is also based on our company's unique high-frequency inverter

technology, compared with the traditional machine, small size, light weight, high conversion

efficiency, energy saving; Compared with imported machine, cheaper, more adaptable to power

grid. To highlight the use of two inverter technology, the pure square wave output, so that the arc

stiffness is good, heat concentration, reverse cleaning ability, wide cleaning range, small current

is not easy to break the arc, etc., to ensure the excellent welder Welding characteristics.

1.3 The welding machine is also equipped with a foot pedal current regulating device, so that the

welder can free the hand to adjust the current with the foot; thus, the current can be quickly

heated when the welding is initial and the wire is added, and the current is reduced at the end of

the welding. Welding pattern formation; the use of the pedal helps to improve welding efficiency,

reduce welding difficulty and ensure welding quality.

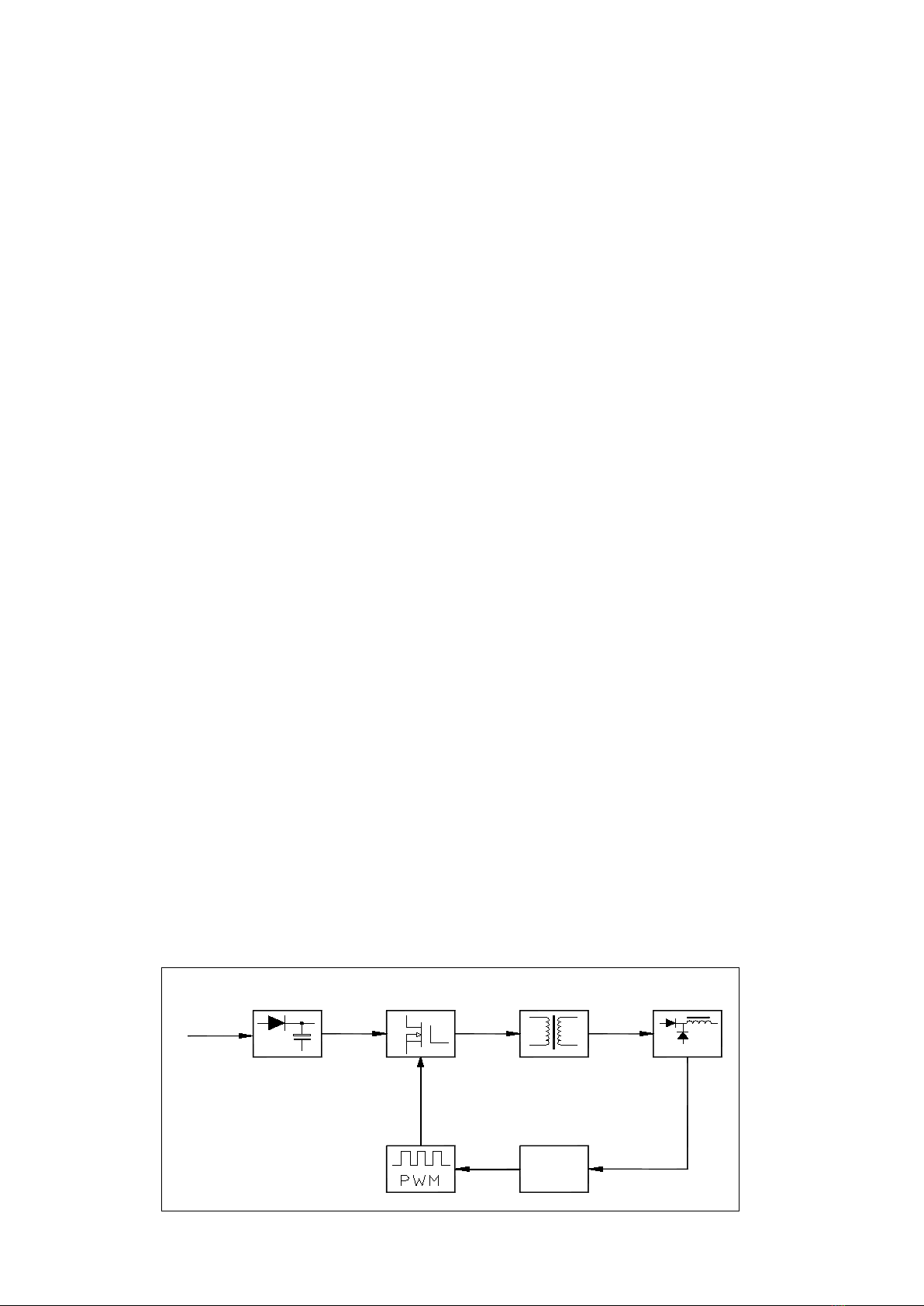

The inverter power supply firstly rectifies the 50 / 60Hz AC to DC, then converts the high-power

switching device (IGBT) into high-frequency voltage through pulse width modulation (PWM), and

then reduces the voltage to rectify, and then outputs the high-power DC power. The volume and

weight of welding machine are greatly reduced by taking inverter technology, and the efficiency

is increased by more than 35%. The features of this series of welding machines are: high

efficiency, energy saving, light weight, no electromagnetic noise, good dynamic characteristics,

stable arc and easy control of molten pool. It has high no-load voltage and good ability

compensation, which is widely used. It can weld stainless steel, alloy steel, carbon steel, copper

and other non-ferrous metals. The machine has four functions: MIG, TIG, CUT, MMA, very flexible

and convenient for all welding workers.

The machine is mainly used in industry. It will produce radio wave, so the worker should make

fully preparation for protection.

Block Diagram