Anderson Thermal Solutions – ANM75 Burner Operation Manual

Anderson Thermal Soluions(Suzhou)Co. ,Ltd.

8

–Set the low gas pressure switch at 50% below the gas pressure measured at the

inlet to the main gas valve train. Set the high gas pressure switch at 50% above the

gas pressure measured at the inlet to the main gas valve train.

–Try to ignite the burner before the purge and other timers have finished their

cycles. Make sure that the flame monitoring system indicates a flame failure.

–Trip out the pressure switches and other limit interlocks. Make sure that the main

gas valve train closes.

–If the simulated limit condition or the simulated flame fault cannot be responded

at the specified fault response time, the fuel system needs to be turned off to

correct the existing problems.

10.8 Burner starting

Special attention:

The ANM75 Series burners, described herein, are designed to mix fuel with air and burn

the mixture. All fuel burning devices are capable of producing fires and explosions, if

improperly applied, installed, adjusted, controlled, or maintained. Do not bypass any

safety feature; fire or explosion could result. Never try to light a burner if it shows signs

of damage or malfunction.

If you are adjusting burner for the first time, you must follow these steps:

1. Reset the system: Start circulating duct fan, close these valves, the automatic gas

valves and manual gas cocks.

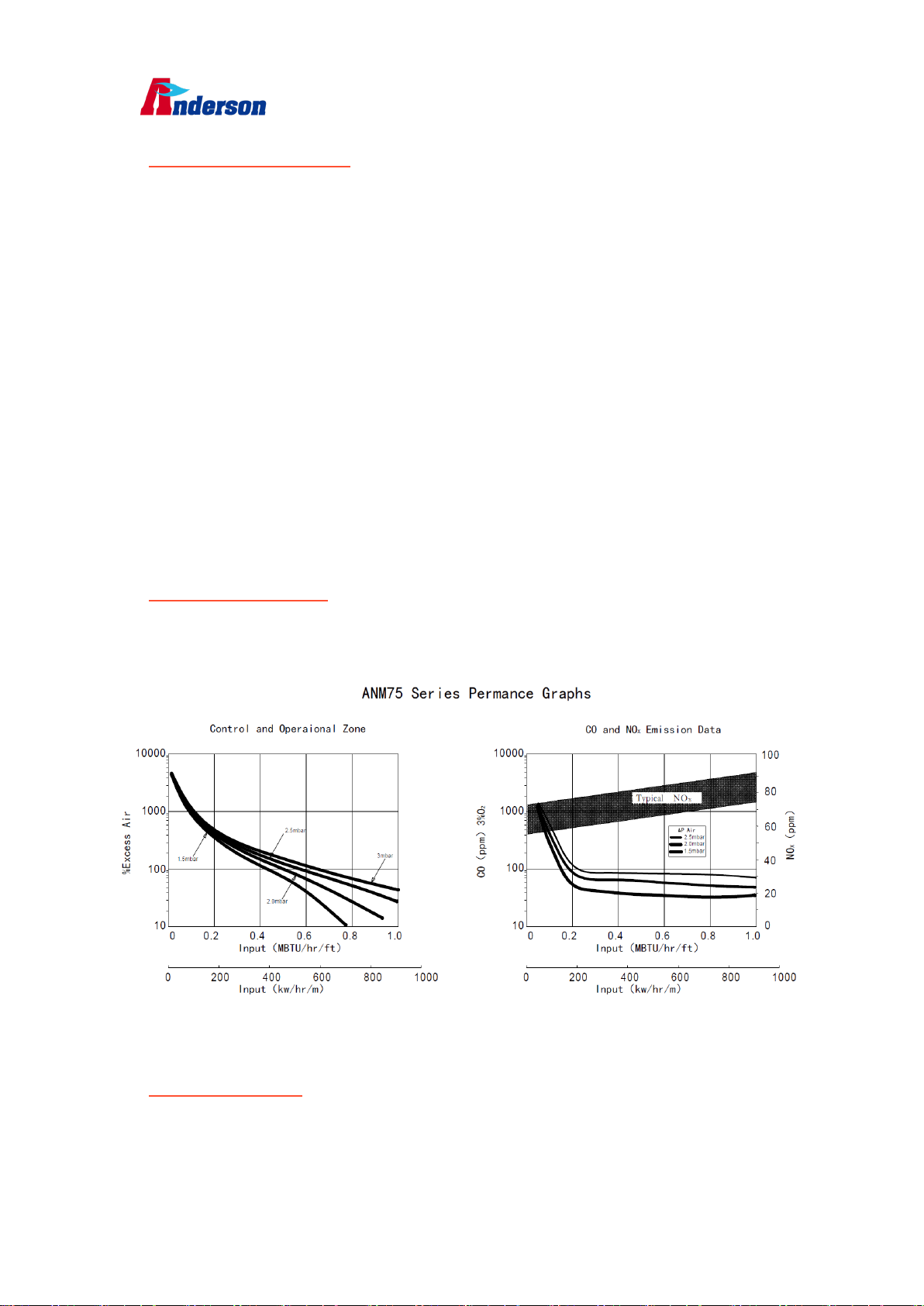

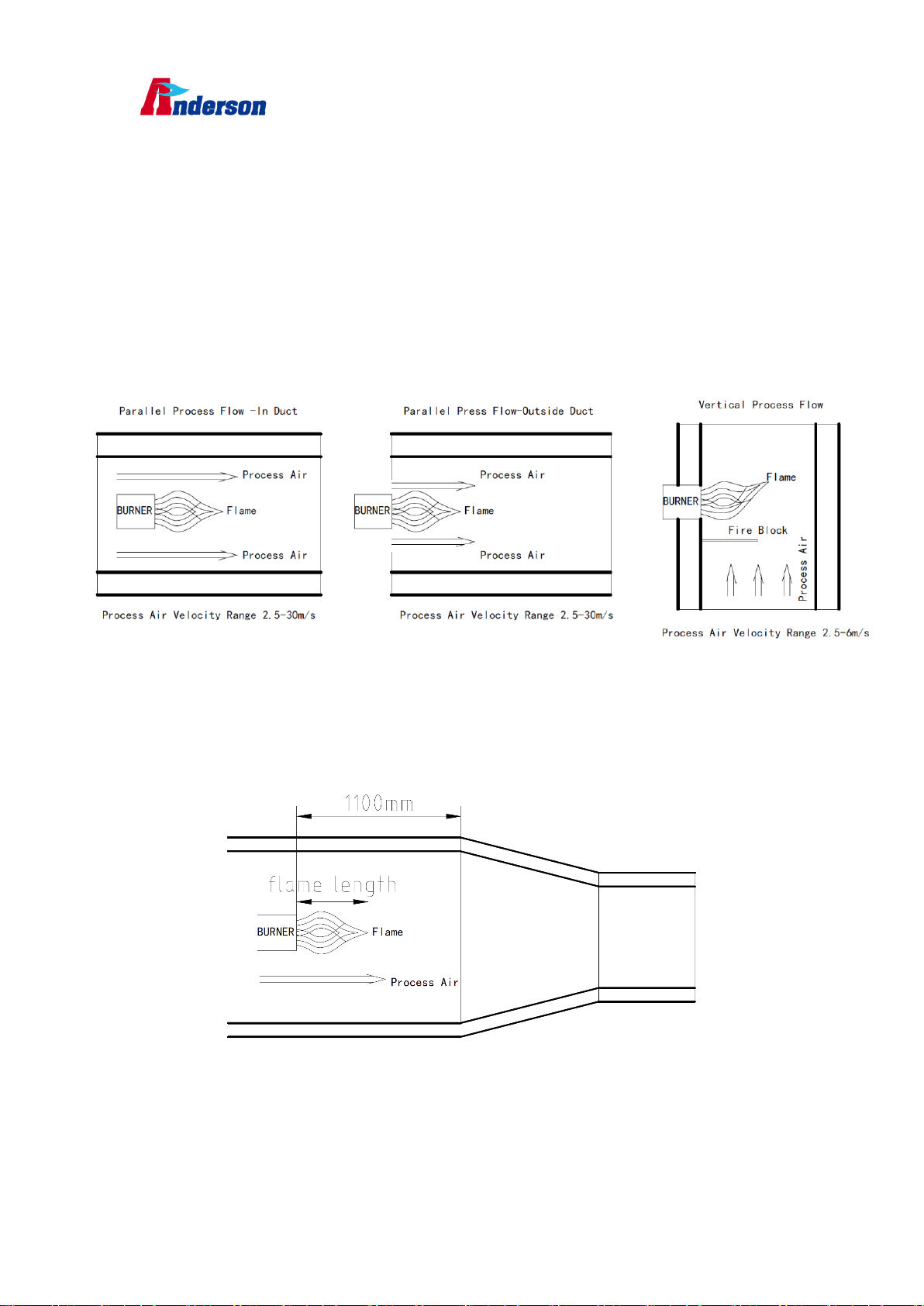

2. Set air flow: Measure the air pressure drop across the burner inlet and duct. Turn

the disc on the blower air inlet until the air pressure is between1.5 to 3.0 mbar. For

a given input, lower air pressure drops will produce a longer flame, and higher

drops will produce a shorter flame with slightly higher CO levels

3. Burner ignition: The gas actuator gets ignition position, the spark plug starts ignition,

at the same time, pilot gas valve open let gas go through the burner to get flame

which is detected by flame or UV scanner to establishes stable pilot flame.

4. Main gas valve open after pilot flame established to set up main flame, all the

ignition process finished.

5. Set high/ low fire gas:Drive the gas actuator to the high fire position, adjust the

outlet of the pressure regulate according to the combustion parameter diagram,

set the gas flow. Then drive the actuator to low fire position, adjust valve opening,

setting gas flow, then get to the high fire position again, adjust gas flow for the

second time, driving again to low fire position to set gas flow to make sure that all

settings are still the same. Do this cycle several times between high and low fire

until satisfied.

6. Determine gas flow: After several cycles of high and low fire positions, check

whether the gas flow at different load positions is similar in same position. It is very

difficult to measure the very low gas pressures experienced at low fire, and it may

be necessary to rely on visual inspection of the flame. This is especially true when

gas turndowns in excess of 20 to 1 are being used. The main intent is to provide a

stable flame with good flame signal that will not cause the chamber temperature