7

www.ecoflam-burners.com

EN

420010518600

Contents - Index - General warnings

Overview Conformity declaration 3

Technical data 4

Working diagram 5

Dimensions 6

Contents Index 7

General warnings 7

Conformity declaration 7

Burner description 8

Function General safety functions 9

E-BCU OIL control and safety unit 10

Oil burner pump 11

Installation Burner assembly 12

Electrical connection 13

Checks before commissioning 13

Oil feeding and suction line 14

Start up Setting data table - air regulation 15

Adjusting burner output 16

Oil pressure regulation 16

Service Maintenance 17

Troubleshooting 18

Overview Electrical diagrams 19

Spare parts list 20-21

Important notes

Ecoflam burners have been designed and

built in compliance with all current

regulations and directives.

All burners comply to the safety

and energy saving operation

regulations within the standard

of their respective performance

range.

The burner must not operate out-

side the working range.

The quality is guaranteed by a quality and

management system certified in

accordance with ISO 9001:2008.

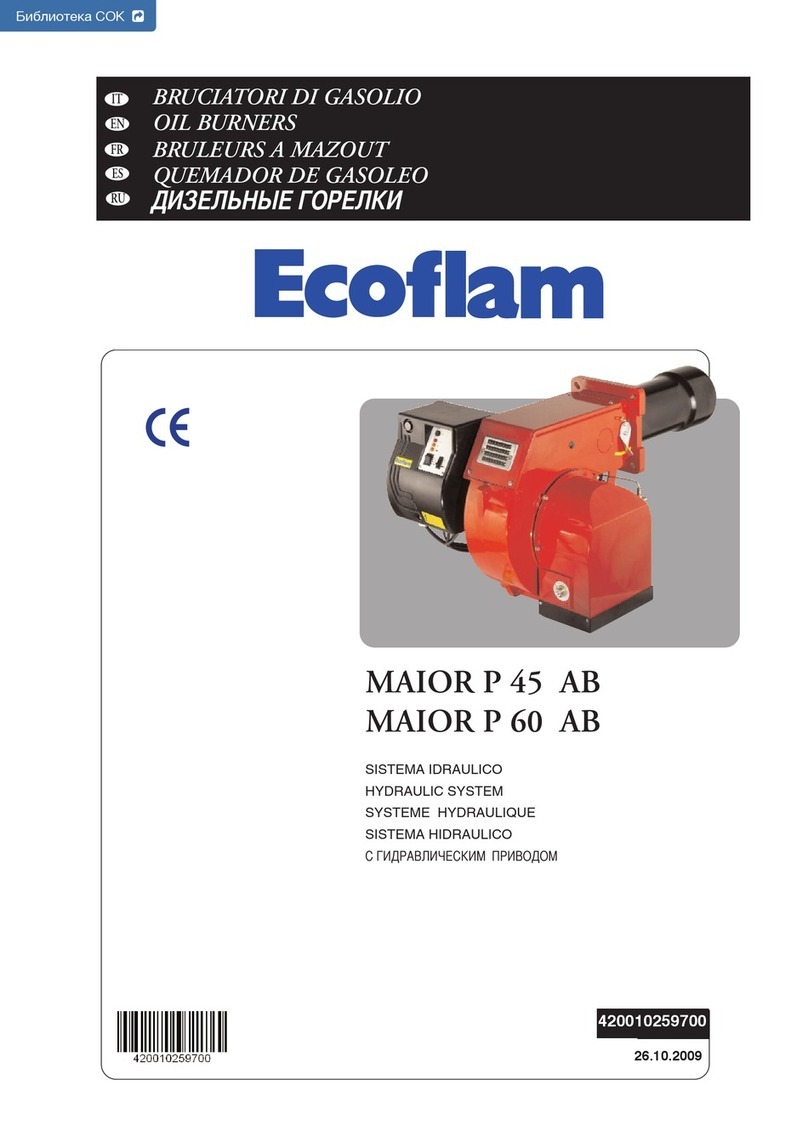

MAX P burners are designed for the low-

pollutant combustion of light oil.

The burners comply with

standard EN267. Assembly and

commissioning must be carried

out only by authorised

specialists and all applicable

guidelines and directives must

be observed.

Burner description

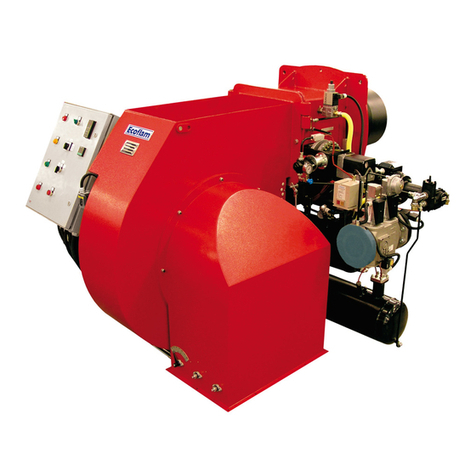

MAX burners are one stage fully automatic

monoblock devices. Burner head is

designed to get the lowest emissions in

terms of NOx and unburnt particles in

order to maximize the heat generator

efficiency. Emissions can be different

respect to the ones recorded in the lab

because they depends a lot on the

generator on which the burner is fit.

The installer must comply with compulsory

rules. Avoid for instance dangerous

atmosphere or not ventilated rooms.

Packaging and handling

Move the burner still in its packaging using

a trolley or forklift, taking care not to drop it

and elevating it no more than 20cm from

ground level. After having removed the

packaging, check that the contents are in

WARNING

DANGER

WARNING

good condition and correspond with what

was ordered. If in doubt, contact the

manufacturer.

The burner must be installed by a

qualified individual.

If the weight and dimensions do not allow

for manual lifting, ask another operator for

help or use a forklift, harness the burner

using belts if no eyebolts are available.

Use the accessories provided

(flange, gasket, pins and nuts) to

install the burner onto the boiler,

taking care not to damage the

isolating gasket.

We can accept no warranty liability

whatsoever for loss, damage or injury

caused by any of the following:

- Inappropriate use.

- Incorrect assembly or repair by the

customer or any third party, including the

fitting of non-original parts.

- non authorised modifications made on

the burner.

Provision of the system and the

operating instructions

The firing system manufacturer must

supply the operator of the system with

operating and maintenance instructions on

or before final delivery. These instructions

should be displayed in a prominent

location at the point of installation of the

heat generator, and should include the

address and telephone number of the

nearest customer service centre.

Notes for the operator

The system should be inspected by a

specialist at least once a year. It is

advisable to take out a maintenance

contract to guarantee regular servicing.

WARNING

WARNING

BURNER SELECTION: Type of

operation and configuration must

be done by professional personnel

in order to grant correct working of

the burner. Installation, start-up and

maintenance must be carried out by

authorised specialists and all applicable

guidelines and regulations (including local

safety regulations and codes of practise)

must be observed.

Installation location

The burner must not be operated in rooms

containing aggressive vapours (e.g. spray,

perchloroethylene, hydrocarbon

tetrachloride, solvent, etc.) or tending to

heavy dust formation or high air humidity.

Adequate ventilation must be provided at

the place of installation of the furnace

system to ensure a reliable supply with

combustion air.

WARNING