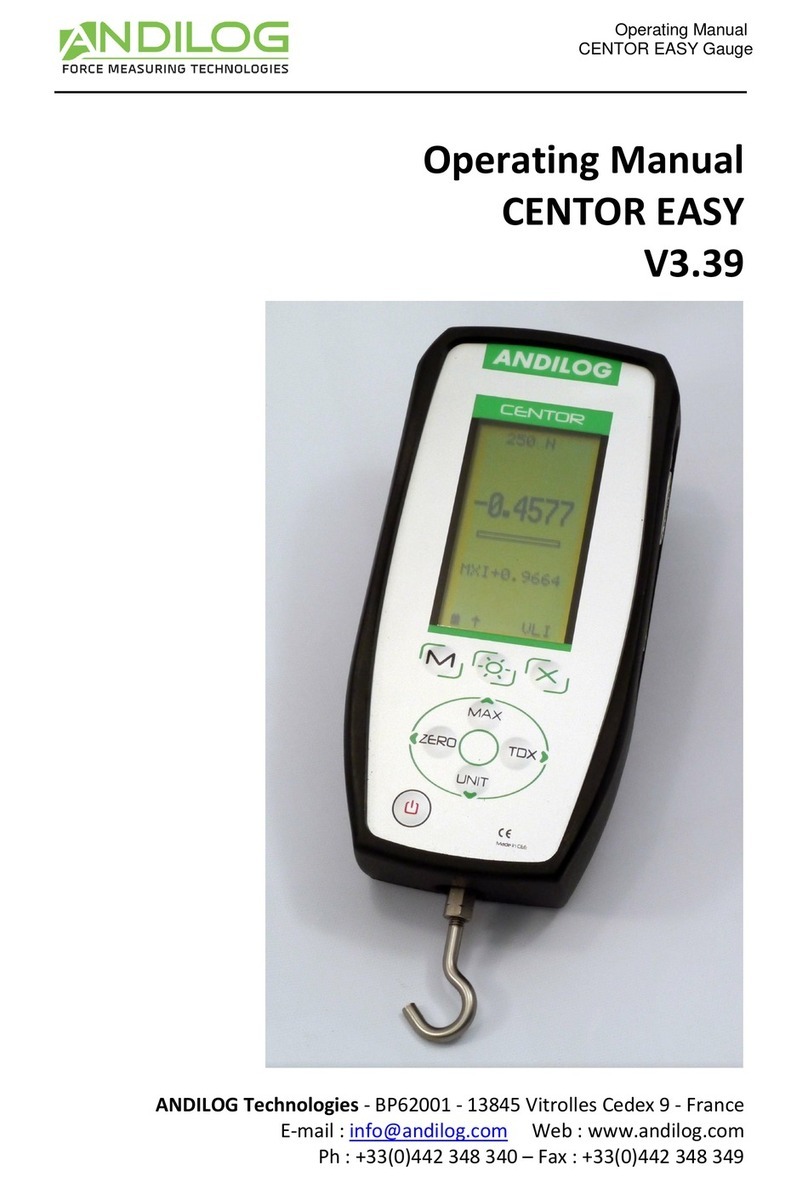

CENTOR EASY II

- 2 -

Contents

1. Introduction..................................................................................................................................... 4

1.1. Presentation ............................................................................................................................ 4

1.2. Recommendations before use ................................................................................................ 4

1.2.1. Battery ............................................................................................................................. 4

1.2.2. Sensor .............................................................................................................................. 4

1.2.3. Test stand ........................................................................................................................ 5

1.2.4. Test precautions .............................................................................................................. 5

1.2.5. Ambient conditions ......................................................................................................... 5

1.2.6. Warranty.......................................................................................................................... 5

2. Getting started ................................................................................................................................ 7

2.1. Battery charging ...................................................................................................................... 7

2.2. Accessories assembly .............................................................................................................. 7

2.2.1. Internal sensor force gauge............................................................................................. 7

2.2.2. External sensor force gauge type S2 or S9 ...................................................................... 7

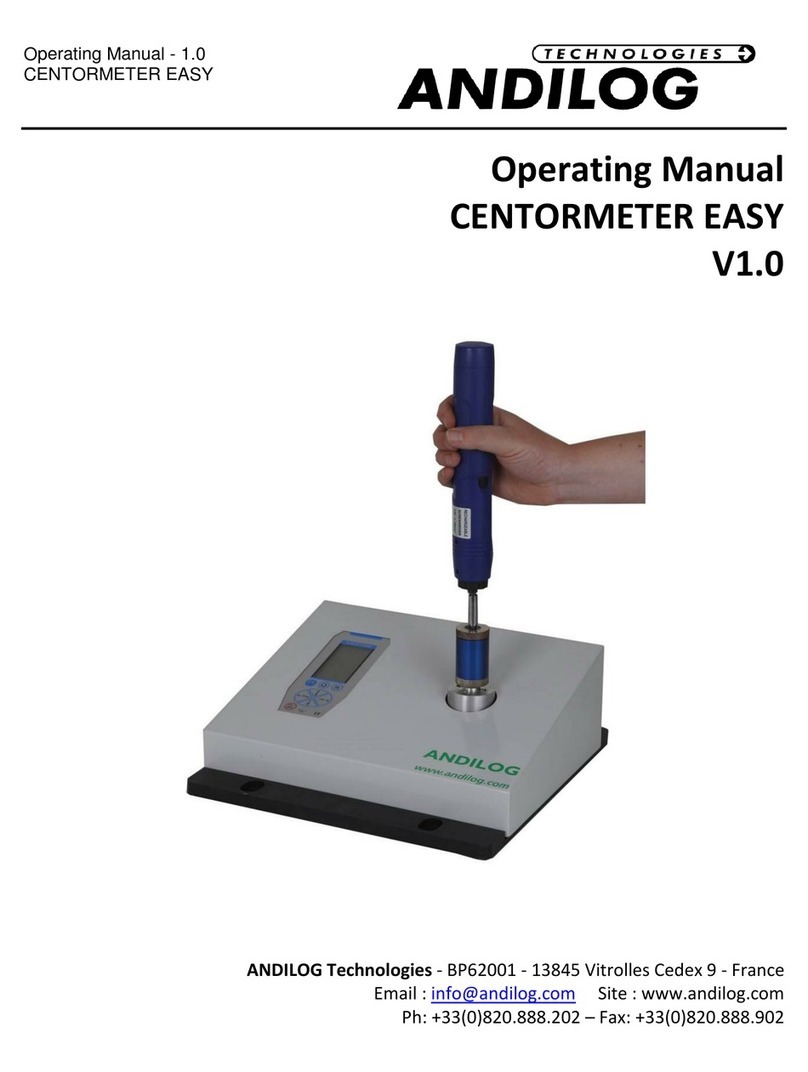

2.2.3. TH torque gauge .............................................................................................................. 9

2.2.4. TW torque gauge ............................................................................................................. 9

2.3. Test stand mounting.............................................................................................................. 10

3. Using the Centor EASY II................................................................................................................ 11

3.1. Start-up.................................................................................................................................. 11

3.2. Switching off.......................................................................................................................... 12

3.3. Measurement screen ............................................................................................................ 13

3.3.1. Go Zero .......................................................................................................................... 14

3.3.2. Change unit of measure ................................................................................................ 15

3.3.3. Change display order..................................................................................................... 15

3.3.4. Auto-off ......................................................................................................................... 15

3.3.5. Memory backup ............................................................................................................ 15

3.4. Menu ..................................................................................................................................... 16

3.4.1. DATA menu.................................................................................................................... 16

3.4.2. SET POINTS menu .......................................................................................................... 17

3.4.3. SYSTEM menu................................................................................................................ 18

3.5. USB communication .............................................................................................................. 19