HOW TO ADJUST

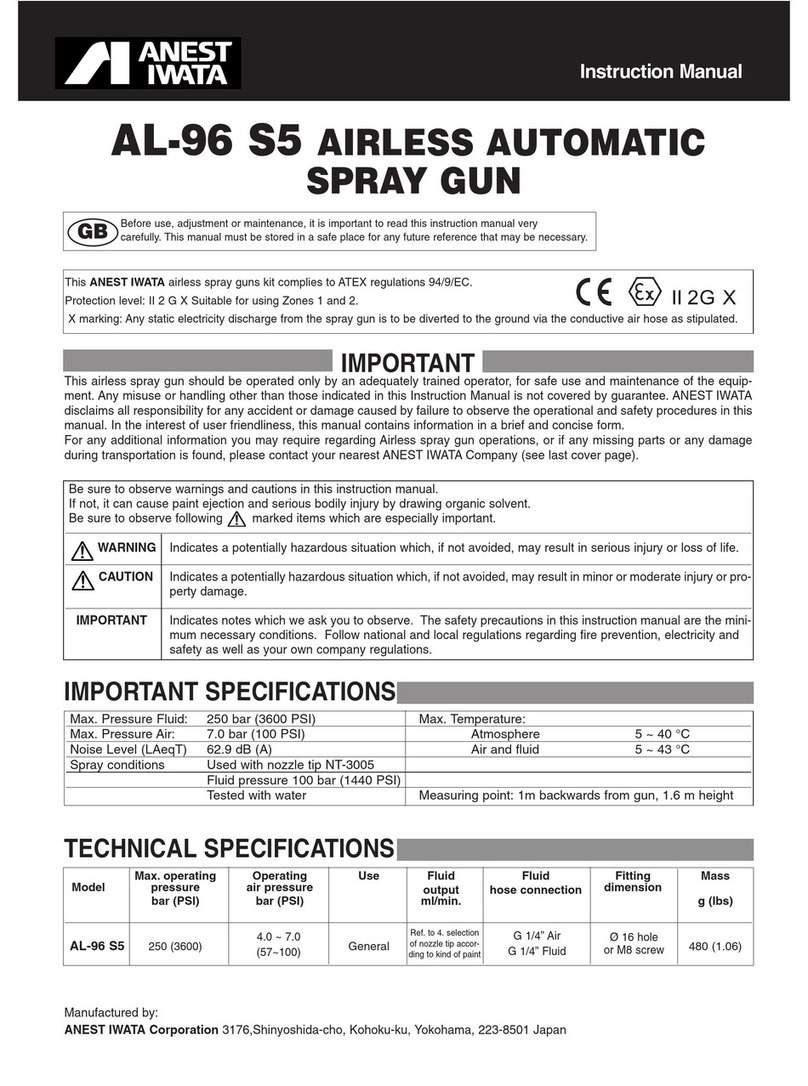

1. Adjust atomizing air pressure varies according to viscosity and paint property. Recommended air pressure is between 2.5-

4.0 bar. (Use higher air pressure to spray fine mist and lower air pressure to spray coarse mist).

2. For TOF-6/6R, set piston operating air pressure to 2.5 bar or more (CYL marked side).

3. When using the pressure feed tank, set its pressure to 2.0 bar or less.

There are two methods to adjust fluid output:

1) Adjust compressed air pressure to the pressure feed tank.

2) Open and close fluid adjustment knob of gun. Fluid output becomes zero when fluid adjustment knob of gun is turned fully

clockwise. Fluid output gradually starts increasing when fluid adjustment knob is turned 0.5 turn counterclockwise from

zero point and fluid output stops increasing when fluid adjustment knob is 4 full turns counterclockwise.

MAINTENANCE AND INSPECTION

54

Step-by-step procedure Important

1. Clean fluid passages and air cap set. 1. Incomplete cleaning can fail pattern shape and uniform particles.

Spray a small amount of thinner to clean fluid passages.

2. Clean each section with brush soaked with thinner and wipe out with waste cloth. 2. Do not immerse the whole gun in thinner. If done, it can damage parts.

When cleaning, never scratch any holes of air cap set, fluid nozzle,

fluid needle set or piston set.

3. Before disassembly, fully clean fluid passages. 3. During disassembly, do not scratch seat section.

(1) Disassemble piston set.

First remove fluid adjustment knob and pull it by holding end of piston. (1) Ensure that piston spring does not suddenly fly out because fluid adjust-

ent knob is strongly pushed by piston spring.

(2) Disassemble fluid nozzle (2) Remove fluid nozzle while piston set is kept pulled backwards,

Use ring spanner and box wrench. in order to protect seated section of fluid nozzle and fluid needle.

(3) Assemble pattern adj. set (3) If pattern adj. set is not fully opened, tip of pattern adj. set can strike

First turn fluid adjustment knob counterclockwise and fully open it, and then gun body and the point of the pattern adjustiment set will collide

insert pattern adj. set into gun body. with gun body, causing damage to both parts.

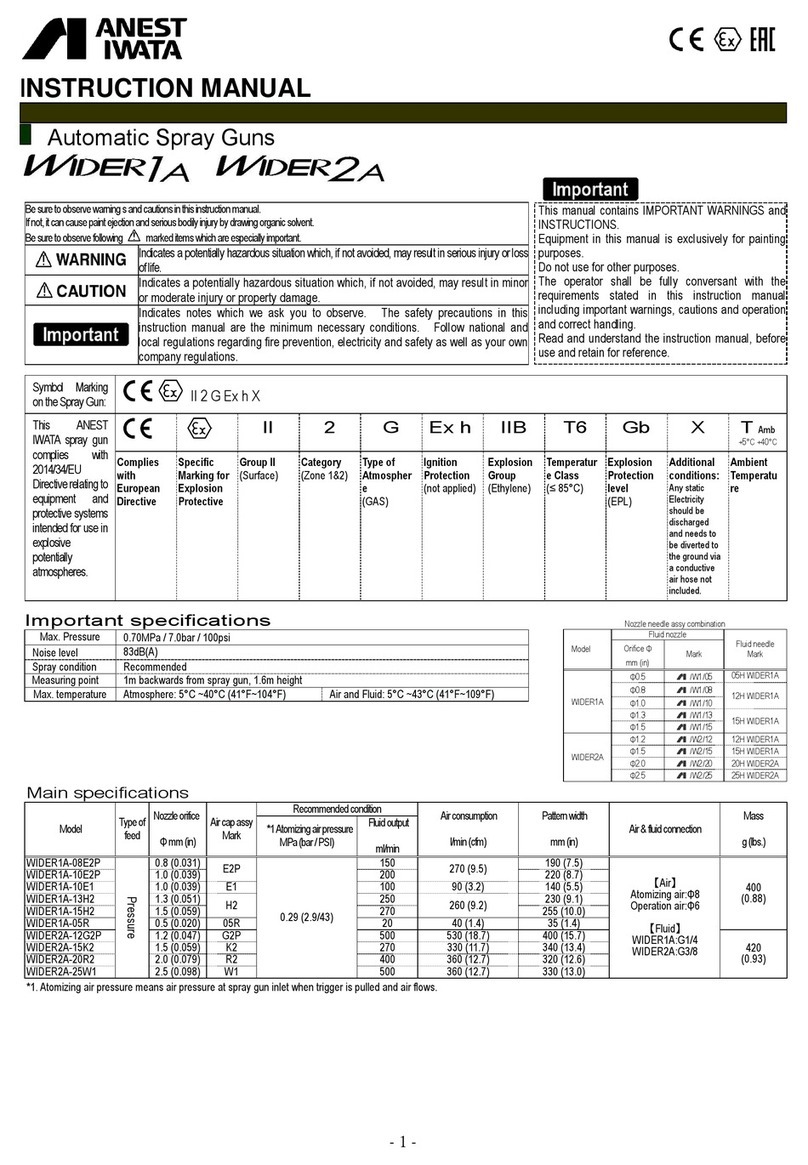

Where to inspect Parts replacement standard

1. Each hole passage of air cap and fluid nozzle. Replace if it is crushed or deformed.

2. Packings and O rings. Replace if it is deformed or worn out.

3. Leakage from seat section between fluid nozzle and piston.

Replace nozzle - piston set if there is any leakage even after cleaning fluid

nozzle and piston.

WARNING

- First fully release air and fluid pressure according to item No. 3 of “Improper use of equipment”

of WARNING on page 2.

- Tip of fluid needle set has a sharp point. Do not touch the tip of needle during maintenance for pro-

tection of the human body.

- Be careful not to damage the tip of the fluid nozzle or put your hand on it.

- Only an experienced person who is fully conversant with the equipment can do maintenance and

inspection.

CAUTION

- Never use commercial or other parts instead of ANEST IWATA original spare parts.

- Never immerse the whole gun into liquid such as thinner.

- Never soak air cap set in solvent for extended period even if cleaning. It can cause defective pattern.

- Never damage holes of air cap, fluid nozzle or fluid needle.

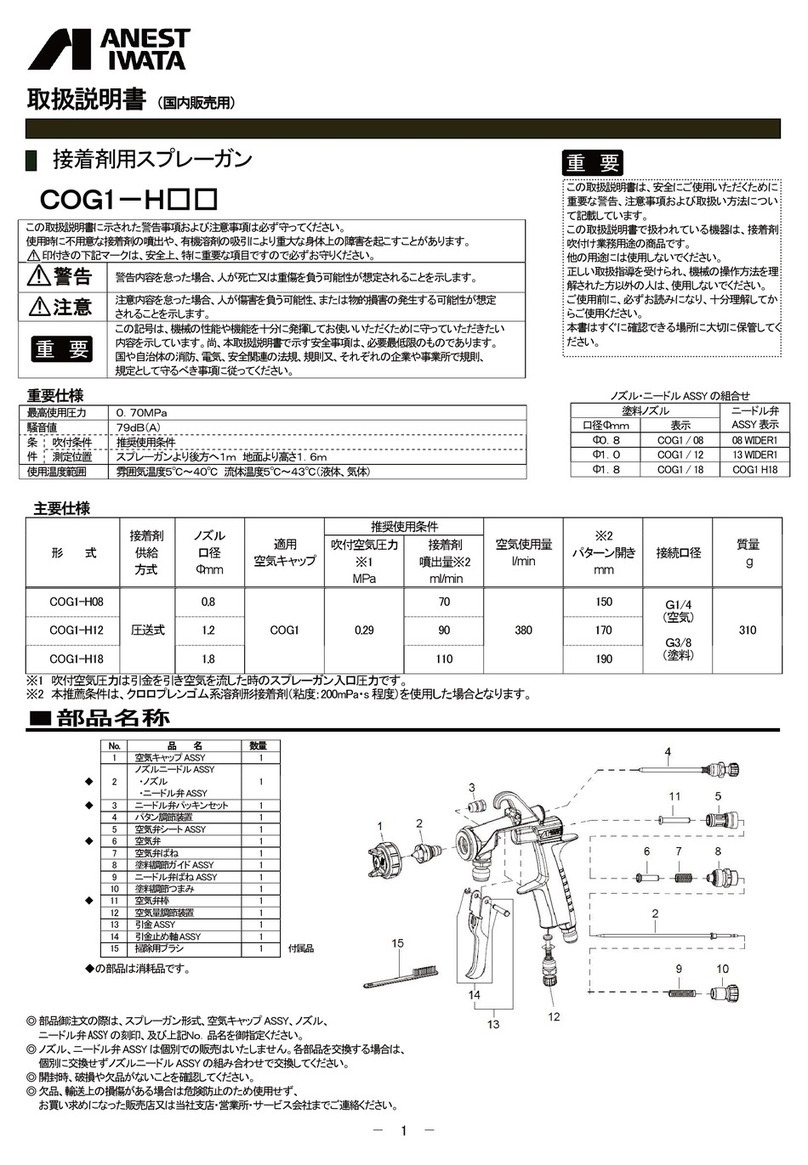

SPARE PARTS LIST

DESCRIPTION REF. PART

AIR CAP SET 1-1

AIR CAP SET (TOF-5R/6R) 1-2

NOZZLE PISTON SET 2

NOZZLE 2-1

PISTON SET 2-2

GUN BODY 3

O-RING SEAT 4

PISTON SPRING 5

PATTERN ADJ. SET 6-1

PLUG (TOF-5R/6R) 6-2

HOLDER 7

JAM NUT 8

BOLT 9

NIPPLE 10

O-RING (P-3) 11

NUT 12

FLUID ADJ. KNOB 13

NUT 14

JOINT 15

Marked parts are wearable parts.

- When ordering parts, specify gun model, part name with

ref. No. and marked No. of air cap set and nozzle

piston set.

- When replacing nozzle or piston, replace it with nozzle-

piston set.

- Before use, be sure to confirm that there is no damage

or missing parts.

- If there is some damage or something is lost during

transportation, do not use the product and contact the

shop which sold it to you.

IMPORTANT

1. One air supply line is used as both atomizing air and piston operating air. So if supply air setting is

not appropriate, it can cause failure of piston operation.

2. Securely lock fluid adjustment knob with jam nut when fluid output has been decided, so that the

the fluid output is not changed by vibrations caused by piston operation and the piston and the pis-

ton spring do not suddenly fly out unexpectedly due to loosening of adjustment knob.