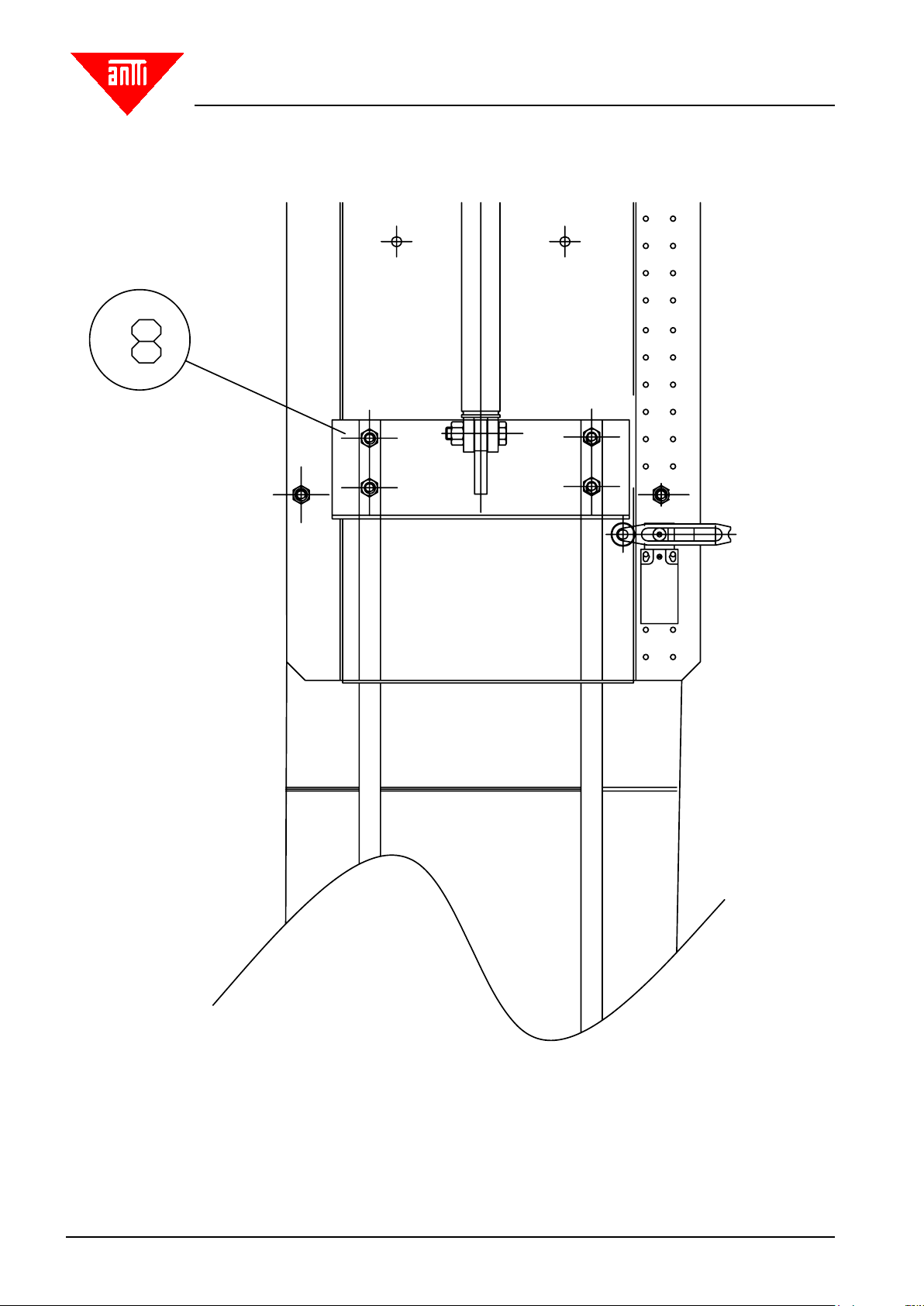

Antti-Teollisuus Oy 9 408012 06-2018

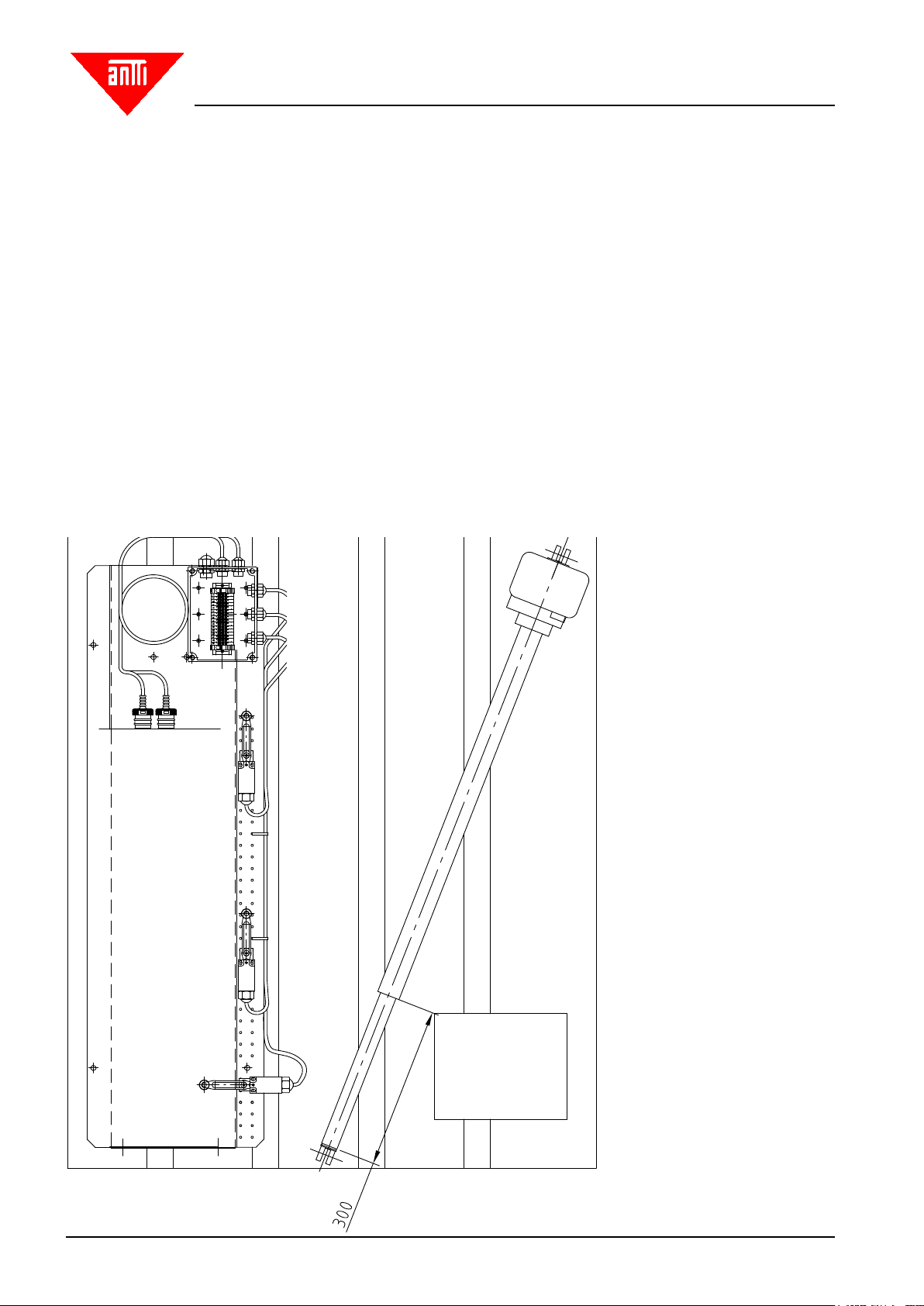

Cutting and attachment of shutter plate rods

COMPRESS TO 35 mm

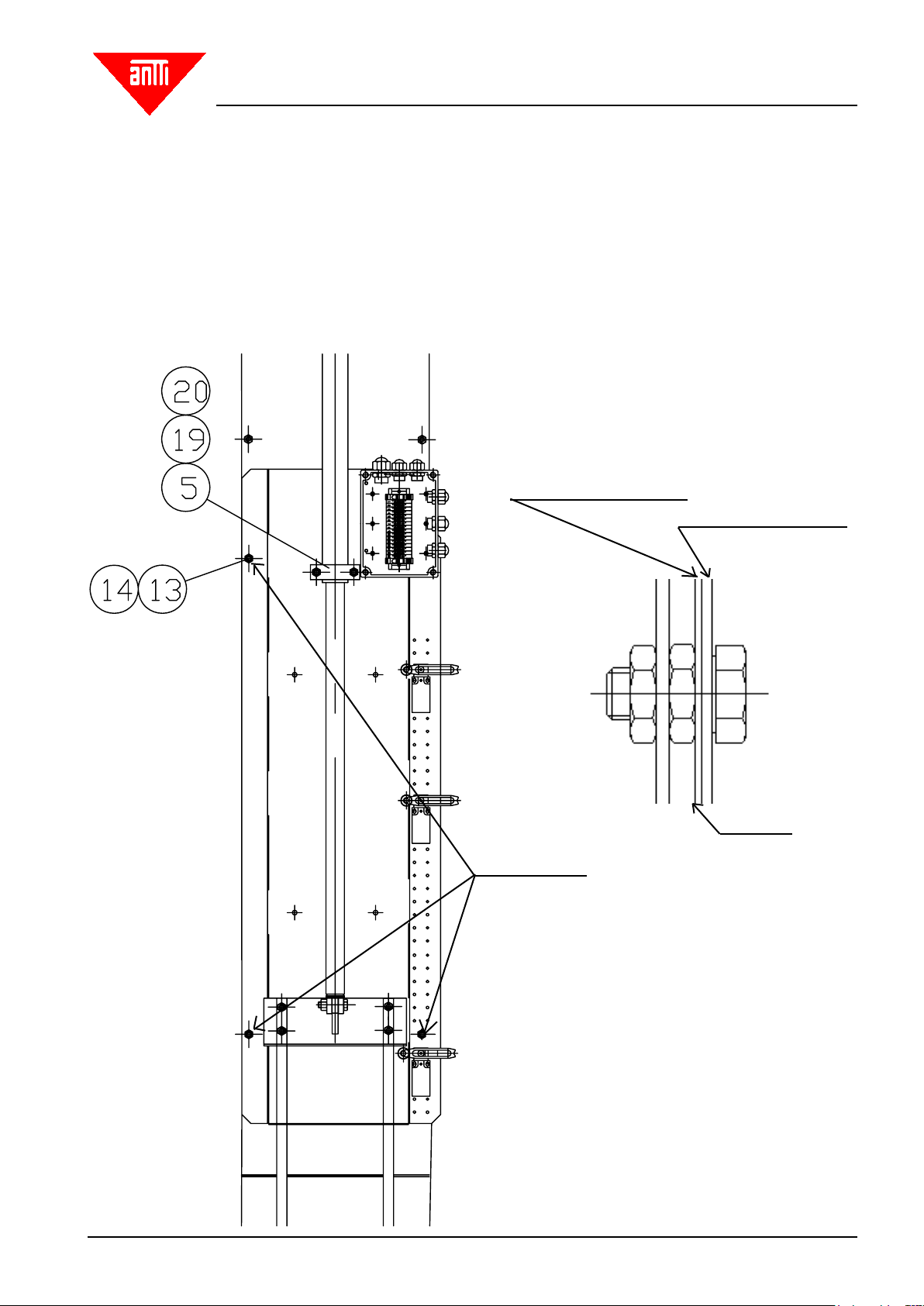

Fig. 6. Attachment to the actuator.

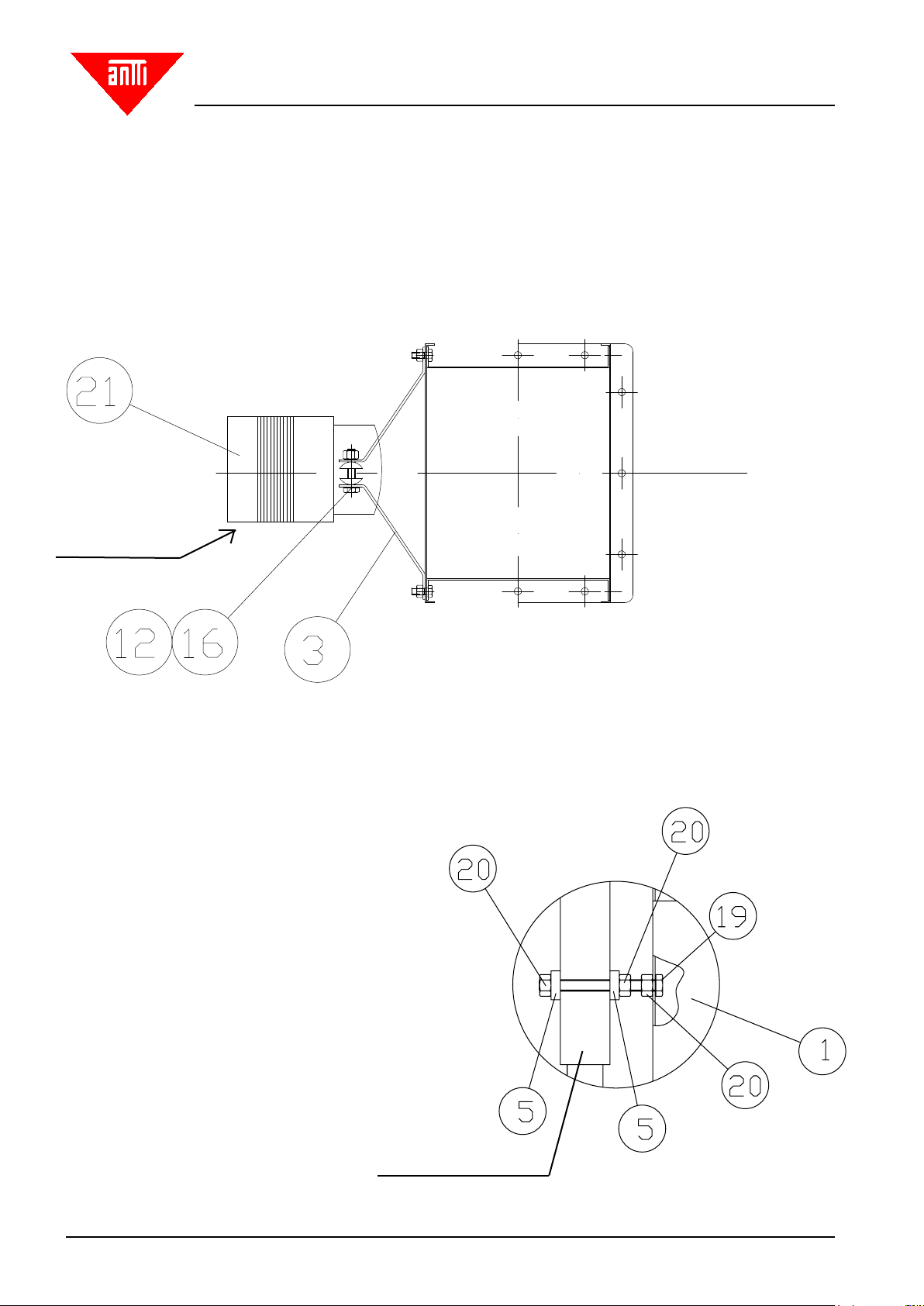

Fig 7. Guides

7. Guide

8. Intermediate rod bracket

9. Shutter plate rod

16. Hexagon screw M12x50

17. Nut M12

Attach the lower ends of the shutter plate

rodsas shown in Fig. 5. Compress the spring to 35mm

by tightening the nut.

Install the rod guides (Fig. 7, part 7) at regulardistances.

Cut the shutter plate rod to such a length that the inter-

mediate rod bracket (Fig. 8, part 8) falls on the lower

limit switch as the shutterplate is closed. Drill 8 mm holes

in the rods for attachment. If necessary, place washers

underthe screws so as to prevent the screw capsfrom

touching the frame plate.

Install the uppermost limit switch in the uppermost

attachment holes.

Finally, lift the intermediate rod bracket to a level where

it can be xed to the linear actuator (Fig. 6).

Fig 5. Fixing the lower end of the shutter plate rod (Fig.

1, detail DET 2) Note that the shutter plate edge must

point away from the elevator pipes.