1 Introduction

1.1 Observations

This lift must only be used by trained people.

Additional copies are available from the manufacturer upon

request.

This manual must always be available to the personnel

responsible for the installation, maintenance and operation

of the service lift.

This manual, including, but not limited to, measurements,

procedures, components, descriptions, instructions,

recommendations and requirements, is subject to change

without prior notice. Please see the manuals section in the

Avanti Website for the latest revisions of the manuals.

Any additional cost relate to or arising from any changes in

the manuals does not entitle the customer to any form of

compensation or other legal remedies.

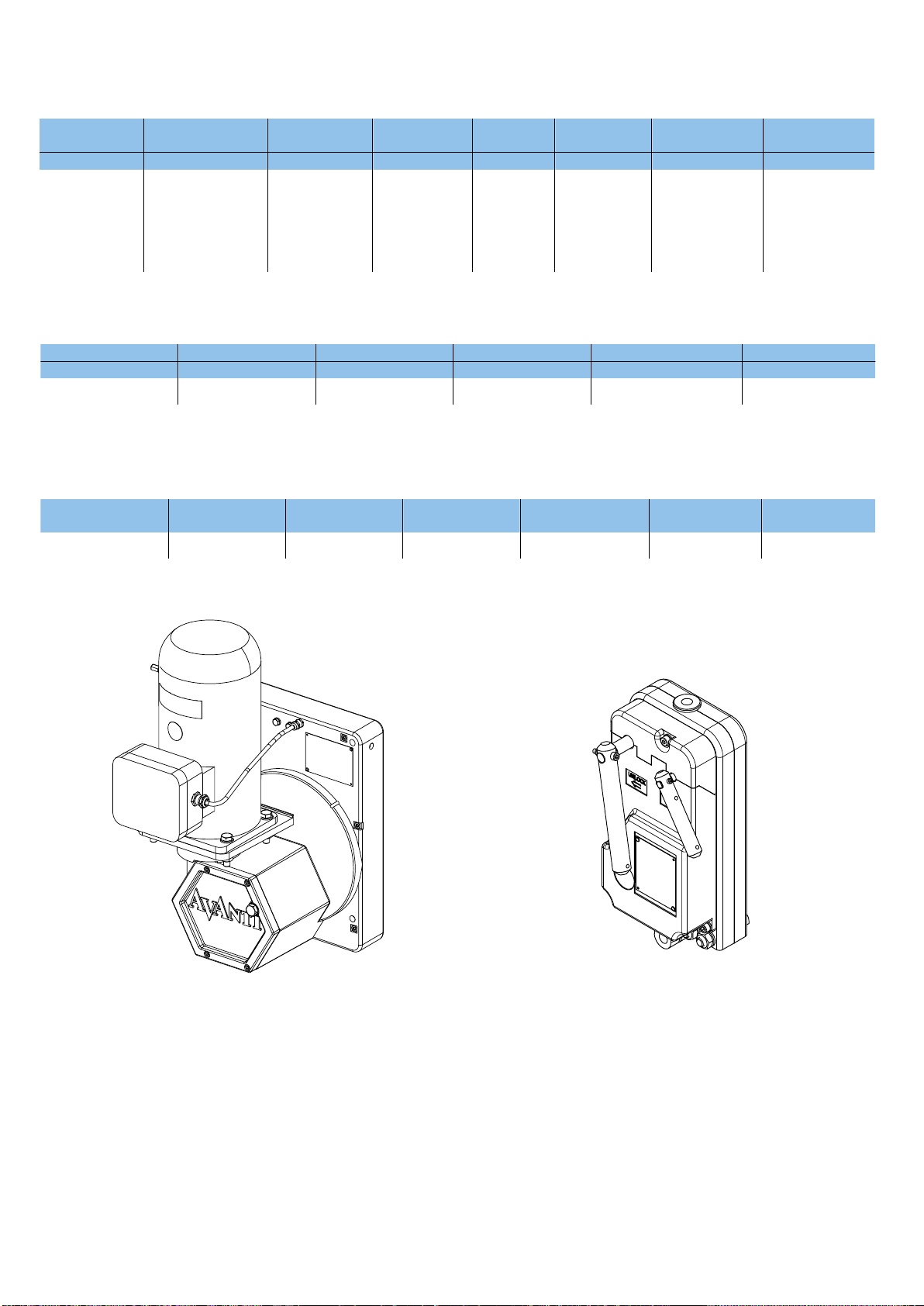

NOTICE

The pictures and diagrams in this manual may not

reflect the exact appearance, colors or layout of the

product. This has no impact on its functionality or

safety.

1.2 Symbols

DANGER

Immediate or possibly imminent danger. Risk of injury

if not observed: Death or severe injury.

WARNING

Potentially hazardous situation. Risk of injury if not

observed: Minor injury or material damage.

CAUTION

Hazardous situation which, if not avoided, could result

in minor or moderate injury.

NOTICE

Useful tips for optimum working procedure.

Possible injury if not observed: None.

1.3 Cautions

Personnel must be of legal age. Personnel must be

familiar with the relevant accident prevention instructions

and must have received appropriate occupational heath

and safety training.

The service lift must not be used by persons who are

under the influence of alcohol or drugs and who may

jeopardize working safety.

Personnel must wear PPE (safety helmet, full body

harness, shock absorber, lanyard and slider) at all times

and carry 2 way communication systems depending on

local regulation.

The service lift is designed for a useful life of 20 years with

an approximate use frequency of 12.5 h/year (250 h in

total).

Installation and maintenance of the service lift must only

be performed by certified technicians. The service lift

must be inspected by a certified technician before its first

use.

The service lift must be inspected at least once a year by

a certified technician. In case of high use frequency or

severe use conditions, more frequent inspections are

required.

If more than one person is entrusted with installation,

inspection or maintenance tasks, the employer must

appoint a supervisor in charge of the operation.

Use and daily inspection of the service lift must only be

performed by persons who have received the relevant

training associated with the use and daily inspection of

the Avanti service lift and who are in possession of a valid

(not expired) certificate for the task.

If any damage or faults are found during operation, or if

circumstances arise which may jeopardize safety:

interrupt the work in progress immediately and notify the

supervisor or employer.

The service lift must not be used in the event of a fire in the

tower.

The service lift must only be used when the turbine is not

generating power.

All wind farm regulations must be followed. The service lift

must not be used during severe weather, including wind

speeds over 25 m/s (55.5 mph).

If any supporting parts are repaired or replaced, the

operational safety of the system must be tested and

verified by a certified technician.

All test / repairs of electrical installations must only

be performed by a certified technician.

All repairs to the traction, braking and supporting systems

may only be performed by a certified technician.

3