MPX Magnetostrictive Level Sensors

Installation Guide

For MPX-T

R

Automation Products Group, Inc.

1025 W 1700 N Logan, UT 84321

Thank You

Thanks for purchasing an MPX-T series magnetostrictive level sensor from us! We appreciate your

business and your trust. Please take a moment to familiarize yourself with the product and this

manual before installation. If you have any questions, at any time, don’t hesitate to call us at 888-

525-7300.

1.Description

2. How To Read Your Label

3. Warranty

4. Dimensions

5. Installation Guidelines &

Instructions

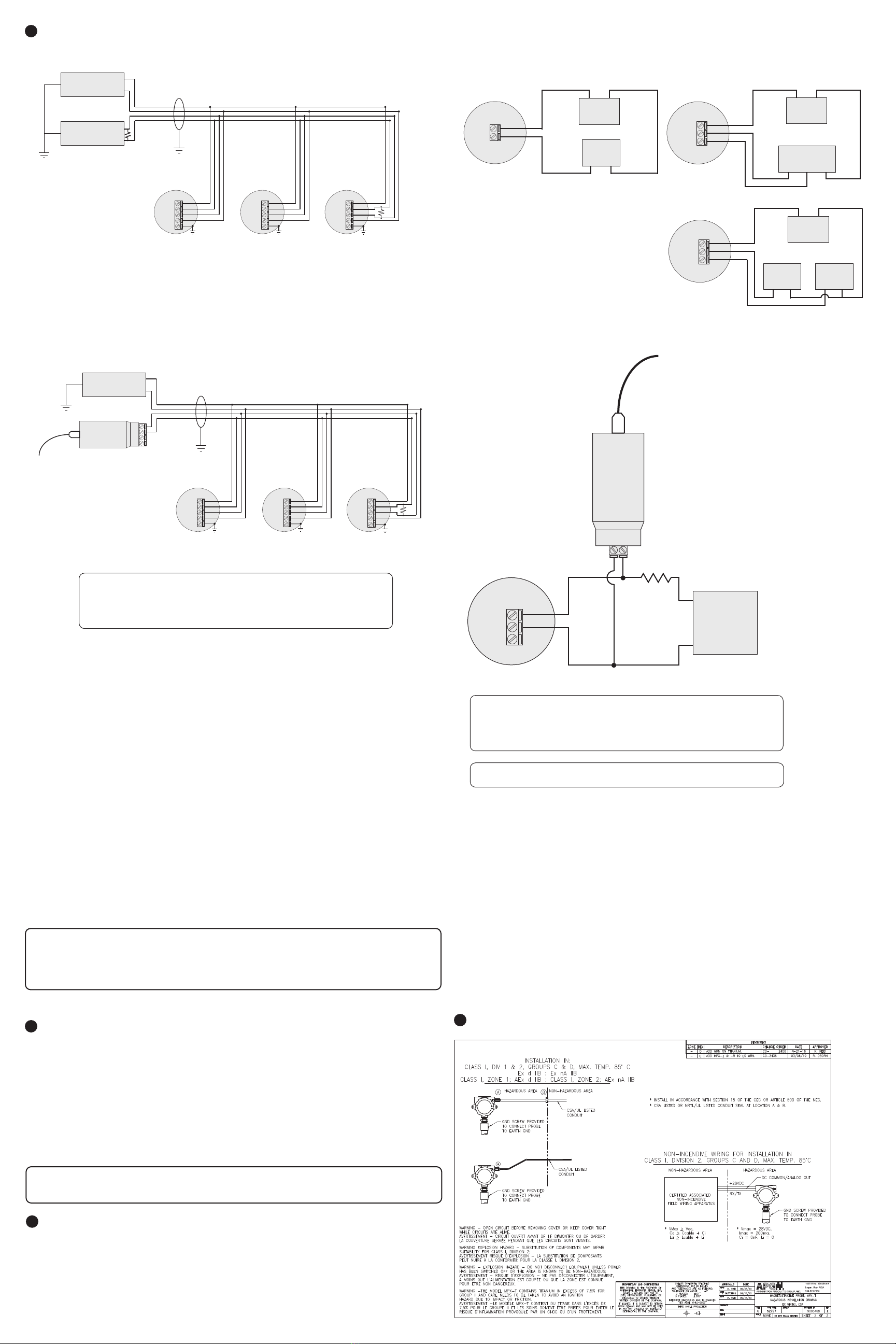

6. Sensor and System Wiring

7. General Care

8. Repair Information

9. Hazardous Location Wiring

Table of Contents

5Installation Guidelines & Instructions

The MPX should be installed in an area--indoors or outdoors--which meets the following

conditions:

• Ambient temperature between -40°C and 85°C (-40°F to +185°F)

• Relative humidity up to 100%

• Altitude up to 2000 meters (6560 feet)

• IEC-664-1 Conductive Pollution Degree 1 or 2

• IEC 61010-1 Measurement Category II

• No chemicals incompatible with Titanium Grade 2

• Ample space for maintenance and inspection

Additional care must be taken to ensure:

• The probe is located away from strong magnetic elds, such as those produced by motors,

transformers, solenoid valves, etc.

• The medium is free from metallic substances and other foreign matter.

• No ignition hazards exist due to impact or friction with the titanium stem.

• The probe is not exposed to excessive vibration.

• The oat(s) t through the mounting hole. If the oat(s) does/do not t, it/they must be

mounted on the stem from inside the vessel being monitored.

• The oat(s) is/are oriented properly on the stem (See Figure 5.1 below). MPX-T oats are

typically installed by customer.

4Dimensions

NOTE: Scan the QR code to the right to see the full

user manual on your tablet or smartphone. Or visit

www.apgsensors.com/support to nd it on our website.

Part # 122950-0032

Doc #9004815 Rev C

Each label comes with a full model number, a part number, and a serial number. The model

number for the MPX will look something like this:

The model number correlates with all the congurable options and tells you exactly what you have.

Compare the model number to the options on the datasheet to identify your exact conguration.

You can also call us with the model, part, or the serial number and we can help you.

You’ll also nd all hazardous certication information on the label.

SAMPLE: MPX-T5B-JI-F4SC-120-3D

The MPX series magnetostrictive level sensor provides highly accurate and repeatable level

readings in a wide variety of liquid level measurement applications. It is certied for installation in

hazardous areas in the US and Canada by CSA for Class I, Division 1 & 2 and Class I, Zones 1 and 2

environments.

1Description

2How To Read Your Label

3Warranty

MPX-T Housing Dimensions

Figure 5.1

UP

Taper

This product is covered by APG’s warranty to be free from defects in material and workmanship

under normal use and service of the product for 24 months. For a full explanation of our Warranty,

please visit https://www.apgsensors.com/about-us/terms-conditions. Contact Technical Support to

receive a Return Material Authorization before shipping your product back.

Scan the QR code below to read the full explanation of our Warranty on your tablet or smartphone.

5.00”

5.71”

Ø 0.27”

4.21”

6.84” - 6.97”

3/4” NPT

1.90”

4.94”

GND

SCREW

ZERO

REFERENCE

3/4” NPT

Housing

Connection

Location

IMPORTANT: MPX-T level sensor MUST be installed according to drawing 9003468

(Hazardous Installation and Non-Incendive Wiring Drawing) in section 9 to meet listed

approvals. Faulty installation will invalidate all safety approvals and ratings.

Warning: -- The model MPX-T contains titanium in excess of 7.5% for Group II and care

needs to be taken to avoid an ignition hazards due to impact or friction;

AVERTISSEMENT -- Le MPX-T modèle contient du titane en excès de 7,5% pour le groupe

II et les soins doivent être prises pour viter une inammation des dangers dus à des

chocs ou frottements.

DANGER: WARNING -- EXPLOSION HAZARD -- SUBSTITUTION OF COMPONENTS MAY

IMPAIR SUITABILITY FOR CLASS I, DIVISION 2;

AVERTISSEMENT -- RISQUE D’EXPLOSION -- LA SUBSTITIOND E COMPOSANTSP EUTR

ENDRE CE MATERIEL INACCEPTABLE POUR LES EMPLACEMENTS DE CLASSE I, DIVISION

2.

DANGER: WARNING -- EXPLOSION HAZARD -- DO NOT DISCONNECT EQUIPMENT

UNLESS POWER HAS BEEN SWITCHED OFF OR THE AREA IS KNOWN TO BE NON-

HAZARDOUS;

AVERTISSEMENT -- RISQUE D’EXPLOSION -- AVANT DE DECONNECTER L’EQUIPEMENT,

COUPER LE COURANT OU S’ASSURER QUE L’EMPLACEMENT EST DESIGNE NON

DANGEREUX.

DANGER: OPEN CIRCUIT BEFORE REMOVING COVER or KEEP COVER TIGHT WHILE

CIRCUITS ARE ALIVE;

AVERTISSEMENT -- OUVRIR LE CIRCUIT AVANT D’ENLEVER LE COUVERCLE, or GARDER LE

COUVERCLE BIEN FERME TANT QUE LES CIRCUITS SONT SOUS TENSION.

IMPORTANT: Floats must be oriented properly on

the stem, or sensor readings will be inaccurate and

unreliable. Untapered oats will have a sticker or “N”

indicating the top of the oat. Remove sticker prior to

use.

Installation Instructions:

• If your sensor’s stem and oats t through the mounting hole, carefully lower the assembly

into the vessel, then secure the sensor to the vessel.

• If the oats do not t, mount them on the stem from inside the vessel being monitored. Then

secure the sensor to the vessel.

• For sensors with oat stops, refer to the assembly drawing included with the sensor for oat

stop installation locations.

Electrical Installation Instructions:

• Remove the housing cover of your MPX.

• Feed system wires into MPX through 3/4” NPT conduit openings. Fittings must be UL/CSA

Listed for CSA installation and IP65 Rated or better.

• Connect wires to MPX terminals. Use crimped ferruls on wires, if possible.

• Replace housing cover.

• For EMI protection on MPX-T4 and -T5 models, either connect the grounding screw (see

Dimensions section 4) to an earth ground, or ensure that tank mounting of MPX is grounded.

See Electrical Connections and System Wiring Diagrams (section 6) for Modbus and 4-20 mA

wiring examples.

IMPORTANT: WARNING -- A SEAL SHALL BE INSTALLED WITHIN 18 inches OF THE

ENCLOSURE;

AVERTISSEMENT -- UN SCELLEMENT DOIT ETRE INSTALLÉ A MOINS DE 18 inches DU

BOITIER.