Page 9

4 Know Your Coatings

4.1 Coating Properties

Coatings are a blend of resins and additives to create a product that will provide a protective and beautifying surface to

yo

ur

work piece. Different resins have different properties. It is important to use the correct coating to achieve a desired result.

Manufacturers of coatings can control the resin solids content, production viscosity, sheen, color, flow-out enhancement and

other properties. Some products offer ways to adjust the coating properties such as speeding up or slowing down the drying

time, adding catalysts to strengthen the molecular bond or adding flatting agents to lower the sheen. Manufacturers will

ofte

n

give some guidelines on how to thin their product for spray application. There are many different types of spray equipment in

use. Coatings manufacturers cannot address all of them. It is important for the finisher to understand the spray equipment

and to use common sense to arrive at the correct fluid viscosity to produce the best possible results with the selected coating

and the equipmentbeing used.

4.2 Your Choice of Coatings and Viscosity

Extremely thin, watery or light bodied fluids such as inks, aniline dyes and oil stains can generally be used straight from

t

he

can. RTS or Ready to Spray water based finishing products are formulated to be used straight from the can without thinning

with a 3 stage or larger turbine. Most other coating products will need to be thinned anywhere from 10% to 50% depending

on the availableair pressureof the turbinemodel and the propertiesof the coating selected.(see chart below).

Chart A Turbine Performance

TurbineSize Sealed Air Pressure Coating Types

3

STAGE

7.0

PSI

Low-MediumViscosityMaterials

4

STAGE

9.0

PSI

Low-HighViscosityMaterials

5

STAGE

10.0

PSI

Low-HighViscosityMaterials

Using Latex (Emulsion) Paint

Although your turbine spray system is best suited to spray Class A Finish coatings such as lacquers, enamels, urethanes,

varnishes, waterborneand water base etc., you can spray latex (emulsion)house paint if you follow a few simple rules.

First

, it

is generally necessary to thin latex (emulsion) paint. This will vary from as little as 10% to as much as 50% depending on the

model turbine you are using and the quality of the paint used. Second, it is necessary to use a larger nozzle and needle set

in the spray gun (2.0mm or 2.5mm). It is recommended that a latex (emulsion) paint conditioner like Floetrol®, be added to

aid flow-out.These productsare sold at local paint stores.

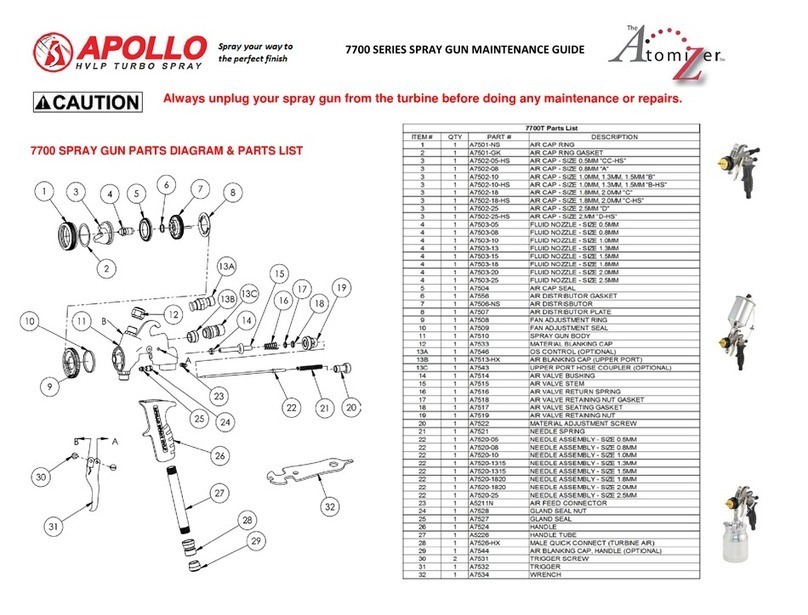

Chart B Nozzle, Needle And Air Caps For 7500 & 7700 Series Spray Guns

Tip/NeedleSize

Application

Air Cap

0.8MM (.029) Inks, Dyes, Stains,

extremely

thin

viscosity

fluids,

W

ater based finishes

A

1.0MM (.039) All purpose,thin lacquers,thin

enamels,W

ater based finishes, Automotive,

Marine,Airplanefinishes

B

1.3MM (.051) All purpose,thin lacquers,thin

enamels, W

ater based finishes, Automotive,

Marine,Airplanefinishes

B

1.5MM (.059) Catalyzed lacquers, Conversion Varnish, Primers,

W

ater based finishes,

Automotive,Marine, Airplane finishes, Varnish, High ViscosityB

OR C IndustrialCoatings, Urethanes, Enamel,

B or C

1.8MM (.070) Catalyzed lacquers, ConversionVarnish, Primers, Automotive,Marine, Airplane

finishes,Varnish, High ViscosityIndustrialCoatings, Urethanes,Enamel

C

2.0MM (.079) Thinned Latex (Emulsion)Paint, Multispec,HeavyPrimers,Butyrate,Nitrate

Dope, C High ViscosityIndustrialCoatings

C

2.5MM (.098) ThinnedLatex (Emulsion)Paint, Multispec, Solvent

adhesives,W

ax based

strippers

D