\\Serveurslce3\DAO\Etude-3d\Aquaset\0-DOSSIER TECHNIQUES\1-sw-plaisance\ESW\09- Manuels Utilisateur\DOC UTILISATEUR ESB FRUKES 2012-11-K.doc VERSION 2012-11-K FR/UK/ES Page 20/39

3 – STOPPING THE WATERMAKER

There is a different procedure after a stop:

-Rinsing: Ensure rinsing of the membrane with fresh water (recommended at every stop) and increase the membrane life : carry out

a rinsing when the watermaker is stopped for 2 weeks maximum.

-Cleaning: Ensure quality of the membrane performance after chemicals cleaning : carry out a cleaning every year (or each 1000

Hours).

-Preservation: Ensure preservation of the membrane with the biocide solution, it is required when the watermaker is stopped for

more than 2 weeks, preservation solution should be renewed every year.

-Wintering: Carry out cleaning and preservation of the watermaker (for a long term period of non-use, clean and renew the

preservation solution every year).

3.1 – SIMPLE STOP

-Turn OFF the unit by closing the main breaker on "OFF" (0).

-After stop of the unit, shut the hull valve (V0).

NB: It is strongly advised to carry out fresh water rinsing each time you stop theunit, this guarantees the longevity of the

membrane and avoids oxidation of metal parts by electrolysis.

If the unit is stopped for a short time (less than 2 weeks) proceed with rinsing (See 3.2).

If it is stopped for a long time, proceed with preservation (See 3.3).

3.2 – STOPPING WITH FRESH WATER FLUSH

Fresh water flush should be carried out before stopping the unit (< 2 weeks). In case of a long stop period, proceed with the

preservation operation.

1. Turn OFF the unit by closing the main breaker on "OFF" (0).

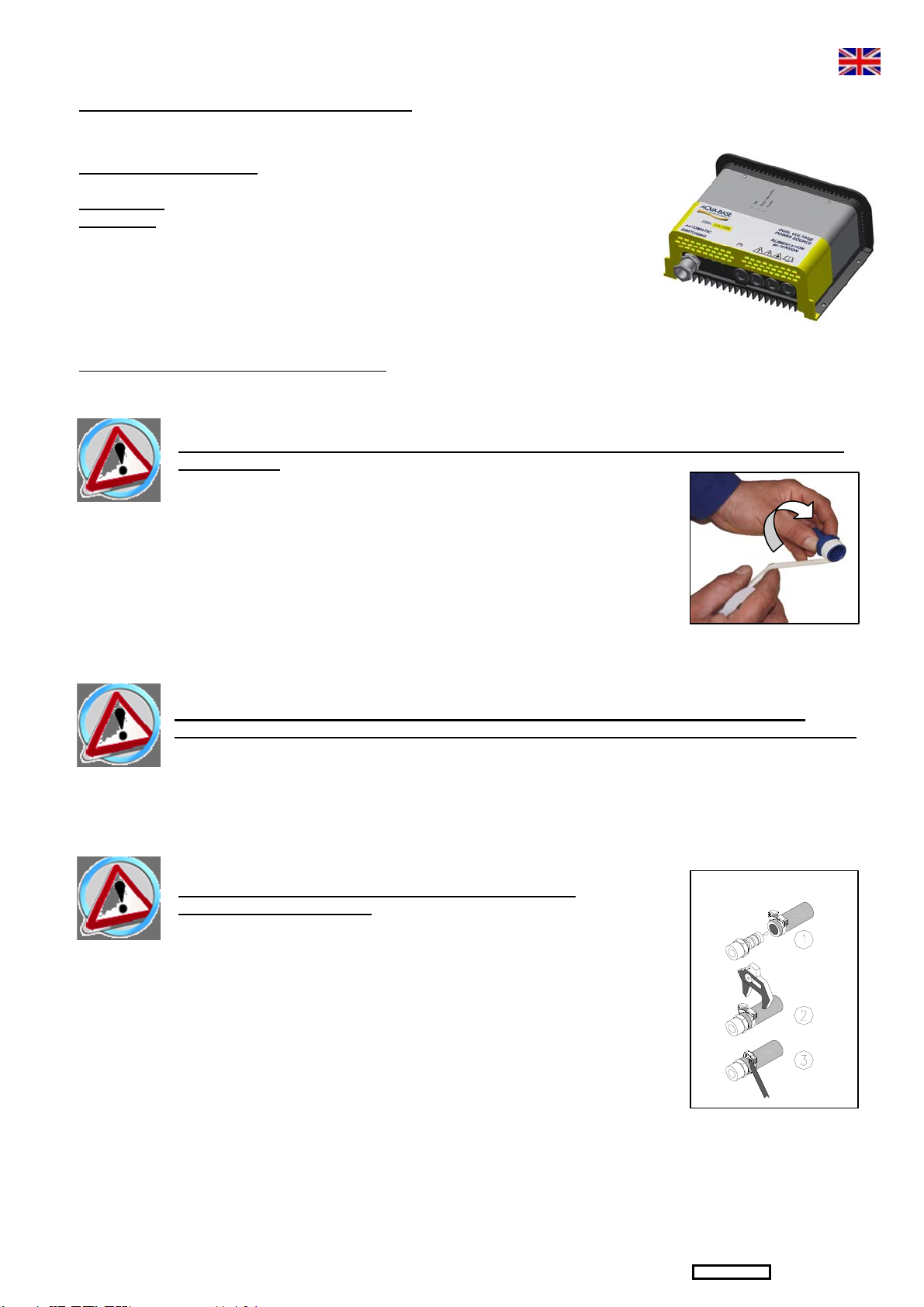

2. Take 10 liters of water from the principal tank, fill the auxiliary tank (bucket) (without chlorine because can damage the membrane).

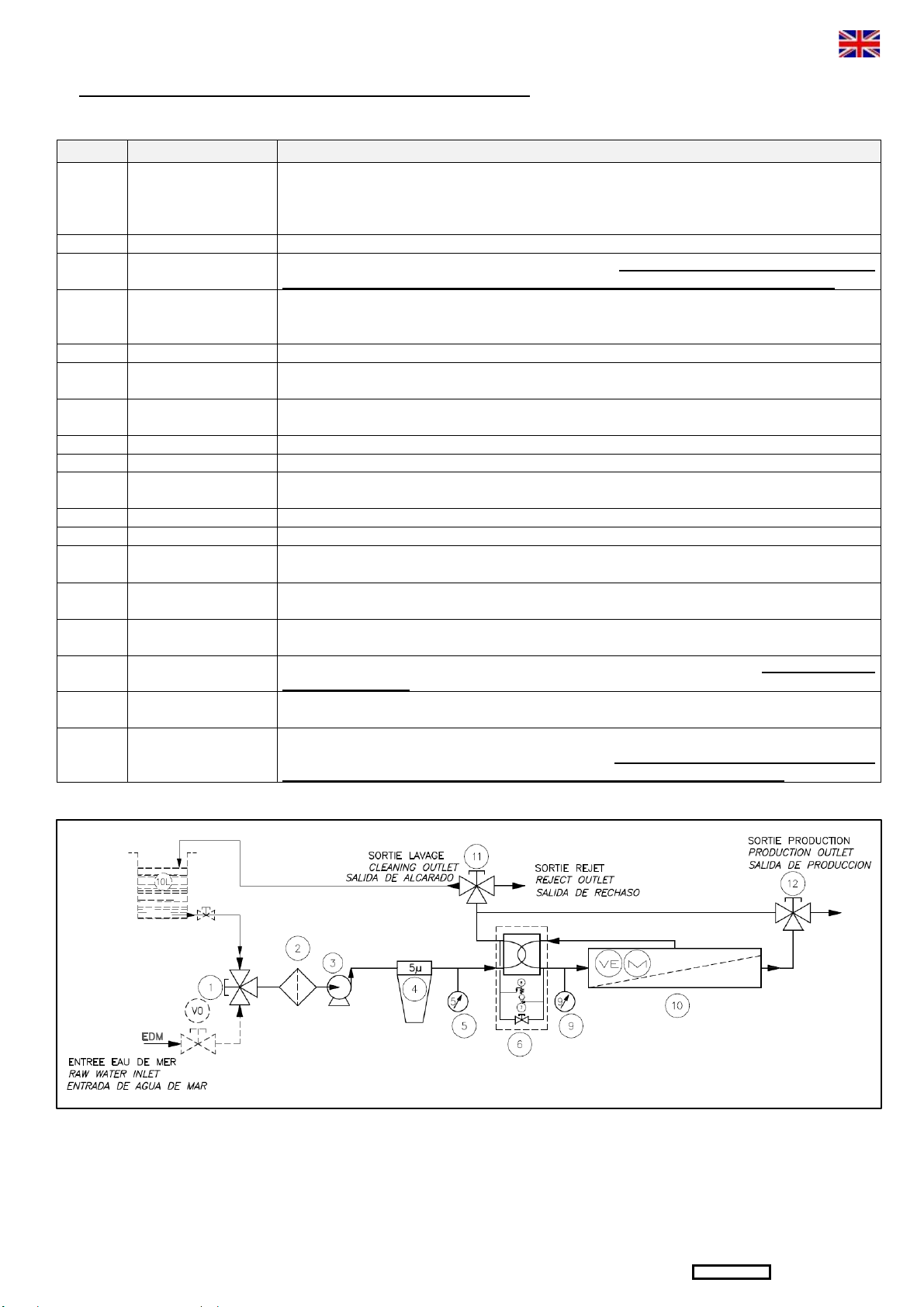

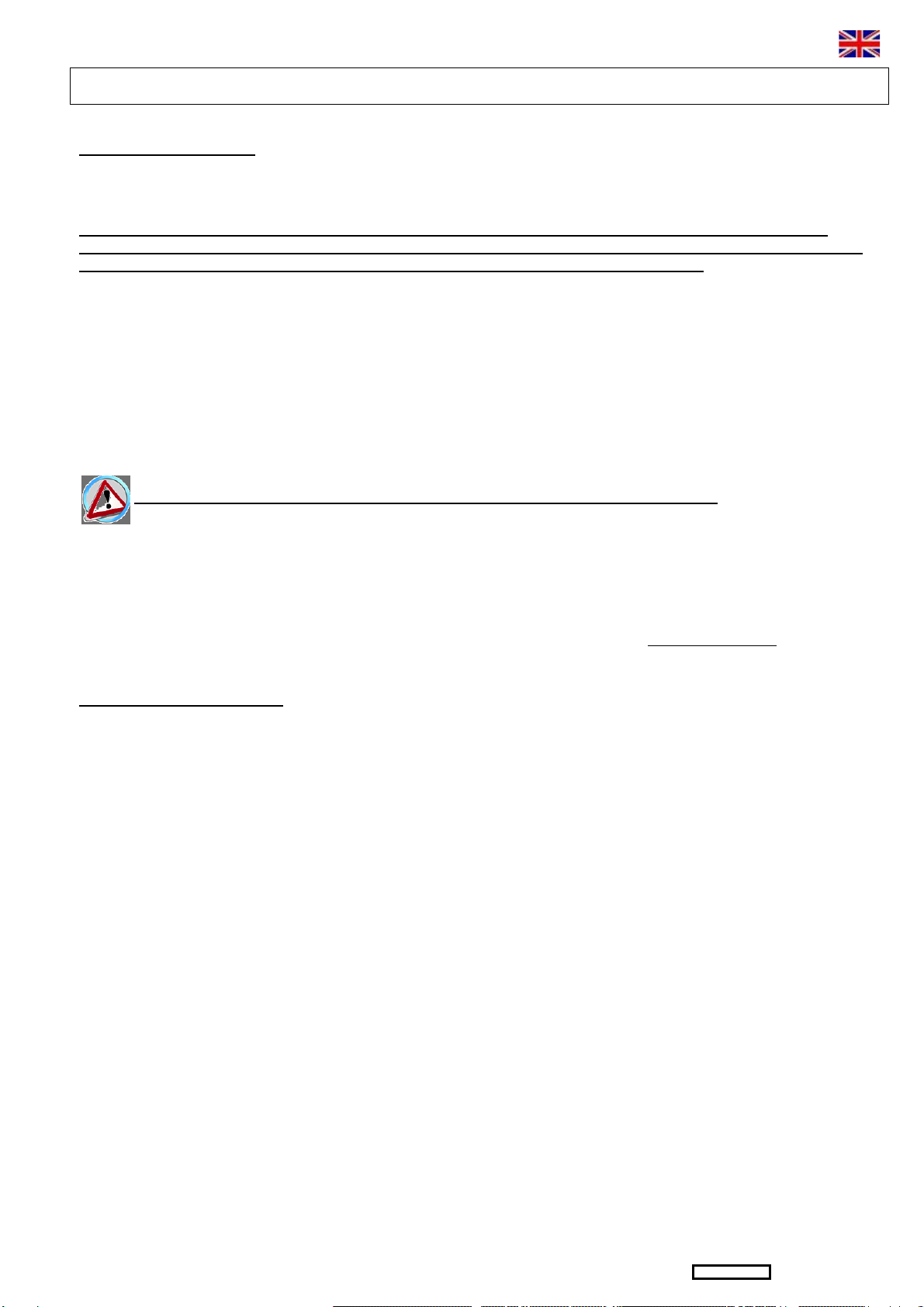

3. Position the inlet valve (1) so as to take water from the auxiliary tank (bucket) and direct it towards the LP pump.

4. Put the cleaning valve (11) in reject position.

5. Put the production valve (12) to reject position.

6. Put the unit ON by opening the main breaker on "ON" (1). Check the level of water in the auxiliary tank (or bucket).

7. Turn OFF the unit by closing the main breaker on "OFF" (0) before the auxiliary tank (or bucket) is empty to avoid air accumulation.

8. When pump is stopped, shut the hull valve (V0) and check valves position (initial position).

3.3 – STOPPING WITH PRESERVATION

BEFORE THE PRESERVATION PROCEDURE, DO A MEMBRANE RINSING (See 3.2)

Fresh water preservation requires the use of an auxiliary tank (or bucket), which should be perfectly clean and FREE OF ANY

TRACES OF GREASY SUBSTANCES. Preservation should imperatively be carried out before stopping the unit over a long period

(more than 2 weeks).

1. Use the preservation liquid (BIOCIDE) - reference AQUA-BASE, Ref. 752002-20.

2. Turn OFF the unit by closing the main breaker on "OFF" (0).

3. Take 10 liters of water from the principal tank, fill the auxiliary tank (bucket) and add the preservation liquid BIOCIDE: mix with the

water.

If the unit is to be stored at a temperature below 0°C, 20% of AQUA-BASE ANTI-FREEZE® ref.752004 must be added to the

preservation solution, during its preparation.

4. Position the inlet valve (1) so as to take water from the auxiliary tank (bucket) and direct it towards the LP pump.

5. Open the air bleed valve (7) of the hydraulic almplifier (6).

6. Put the cleaning valve (11) in reject position

7. Put the production valve (12) to reject position.

8. Put the unit ON by opening the main breaker on "ON" (1). Check the level of water in the auxiliary tank (or bucket).

9. Turn OFF the unit by closing the main breaker on "OFF" (0) before the auxiliary tank (or bucket) is empty to avoid air accumulation.

10. When pump is stopped, shut the hull valve (V0) and check valves position (initial position).

N.B : In order to avoid the PRESERVATION procedure during immobilisation of the unit, operate the unit for a few minutes every

week. It is strongly advised to carry out rinsing by fresh water every time the unit is stopped, as this guarantees the longevity of the

membrane and avoids oxidation of metal parts by electro corrosion.