2

THANK YOU FOR CHOOSING AQUA MARINA

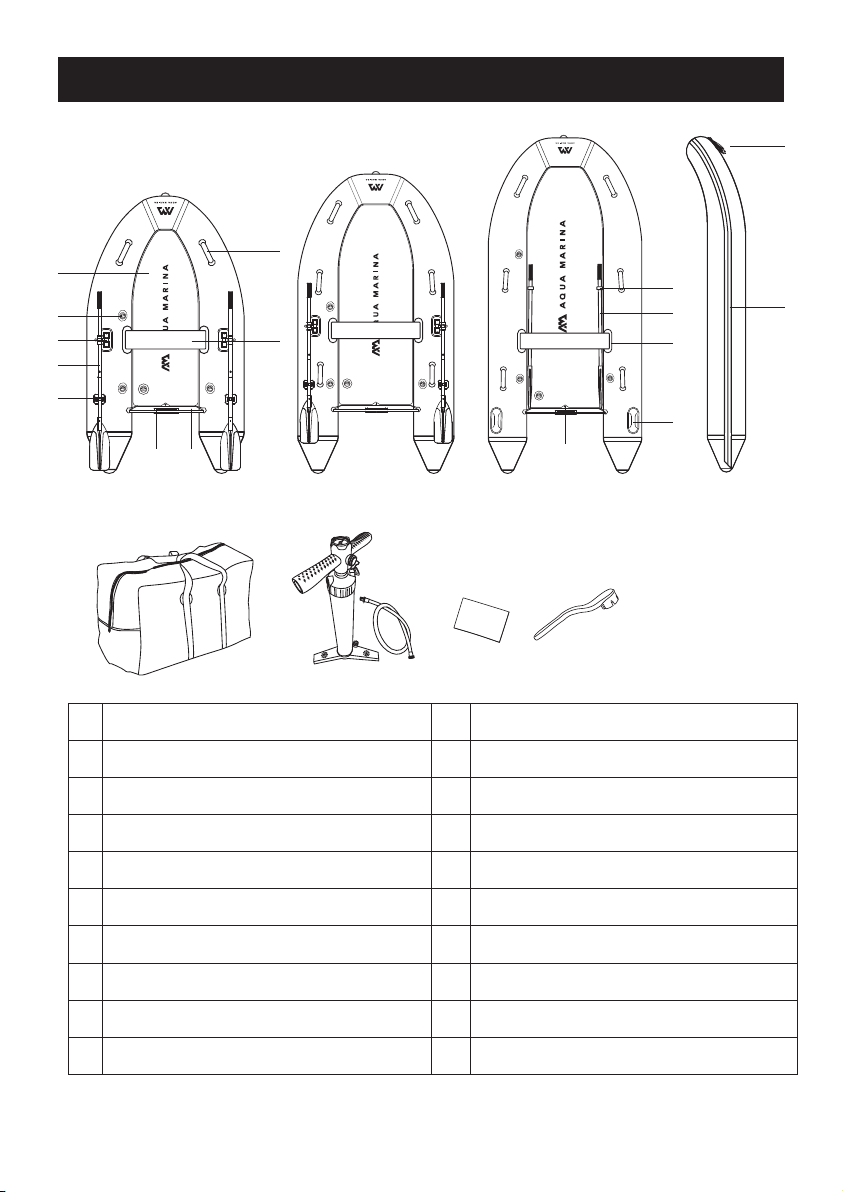

DELUXE SPORT BOATS

Compact and lightweight, these economical inflatable boats are great ship to shore

tender crafts or a highly portable pleasure boat for the boater on the go. Bring your

roll-up boat with you to the lake, the beach or wherever! With a set-up time of just

minutes, no trailers and no special equipment, these boats will allow easy access to

some of those places you've only seen from the shore.

This manual has been compiled to help you achieve long term safe use and pleasure

from your Aqua Marina® boats.

GENERAL INFORMATION

SAFETY

In a manual of this type it is impossible to give adequate space to the topic of water

safety. Check in your local area for information and/or training as needed. Inform

yourself about local regulations and dangers related to boating and/or other water

activities. It is your responsibility to be aware of and comply with all relevant safety

regulations. For all water recreation or sport you should have a reasonable swimming

ability. Just as swimmers have a cardinal rule about not swimming alone. It is strongly

advised that you should never go boating alone.

PLEASE KEEP THIS MANUAL IN A SECURE PLACE, AND HAND IT OVER TO THE NEW

OWNER WHEN YOU SELL THE CRAFT. RECORD THE "HULL IDENTIFICATION

NUMBER" (HIN) WHICH IS LABELLED ON THE BOAT

MANUFACTURER’S CERTIFICATION

Our boats comply with the ISO 6185 standard

established by the International Organization

for Standardization.

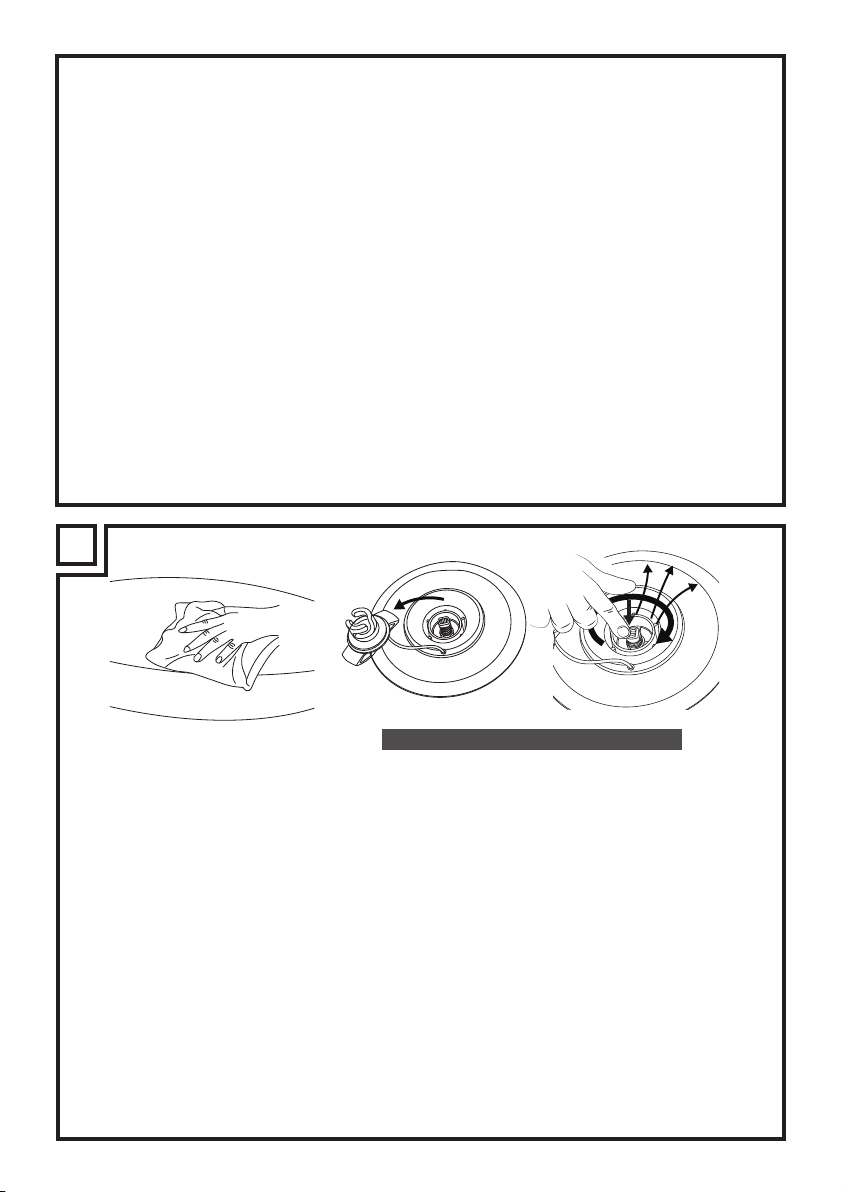

MANUFACTURER’S RECOMMENDATION

The total number of persons, motor power

and total weight shall not exceed the limits

labeled (Fig. 1) on the boat.

S/N

STANDARD EN ISO 6185-2:2018

DESIGN CATEGORY C

BOAT TYPE TYPE V

ORIENTAL RECREATIONAL PRODUCTS (SHANGHAI) CO., LTD

NO. 1699 Da Ye Road, Fengxian, Shanghai, China

WWW.AQUAMARINA.COM MADE IN CHINA

BOAT MODEL BT-UD298

=

11.03

kw

15

HP

=

3

=

1

=

360 kg (792 lbs)

=

0.25 bar (3.62 psi)

1 bar (15 psi) (DECK)

S/N

CN-ORP

DATE

N.W

28 kg (61.7 lbs)

+ +

Fig.1

1

2

3

4

5

6

7

Label format for boat