Inhaltsverzeichnis

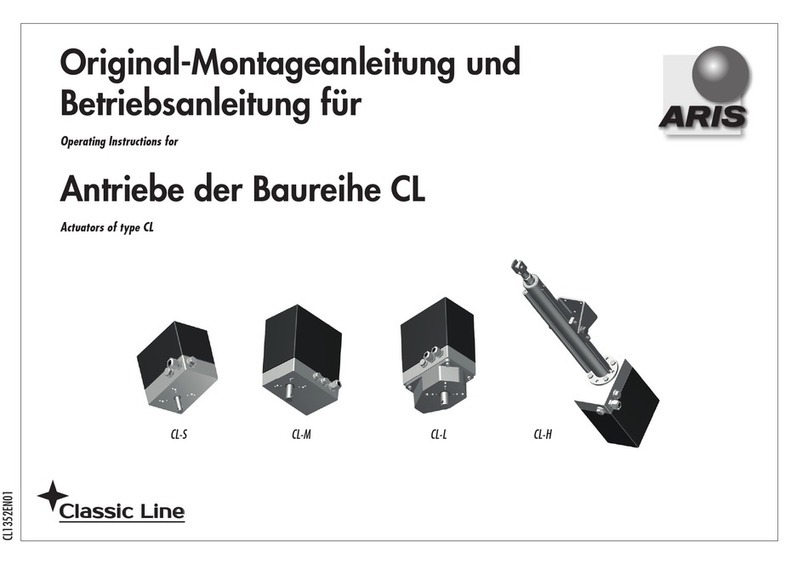

Identication..............................................................................................................................................................................3

Nameplate .................................................................................................................................................................................3

Guidelines and standards............................................................................................................................................................4

Safety information......................................................................................................................................................................4

Warnings.................................................................................................................................................................................... 4

General safety advices................................................................................................................................................................ 4

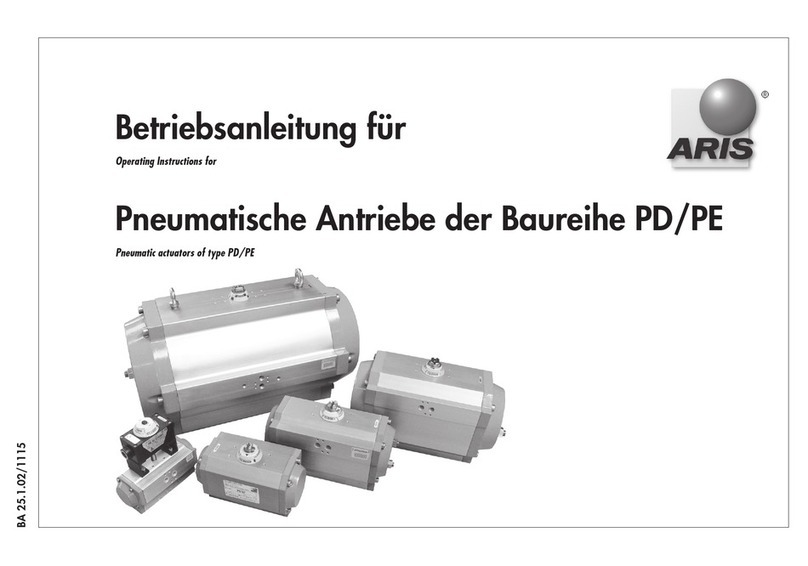

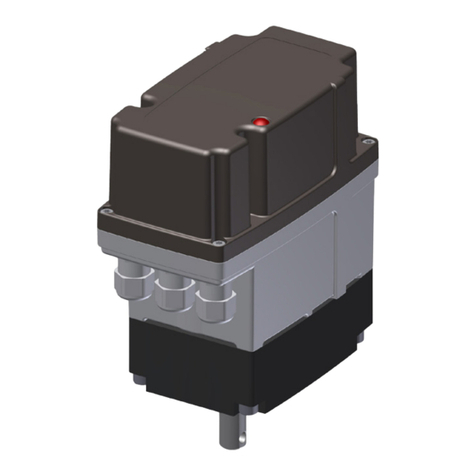

Technical specication.................................................................................................................................................................5

Function and application areas (Intended use)............................................................................................................................. 5

Safe and accurate use.................................................................................................................................................................5

Performance data.......................................................................................................................................................................8

Expected lifespan and intended disposal......................................................................................................................................8

Actuator setup for utilization.......................................................................................................................................................8

Transport and (temporary) storage..............................................................................................................................................8

Packaging..................................................................................................................................................................................9

Safe disposal of packaging.......................................................................................................................................................... 9

Installation and mounting...........................................................................................................................................................9

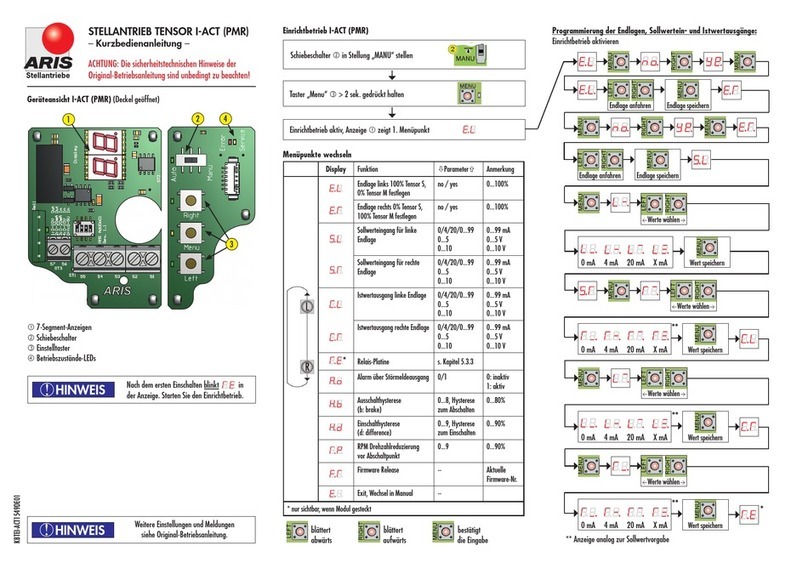

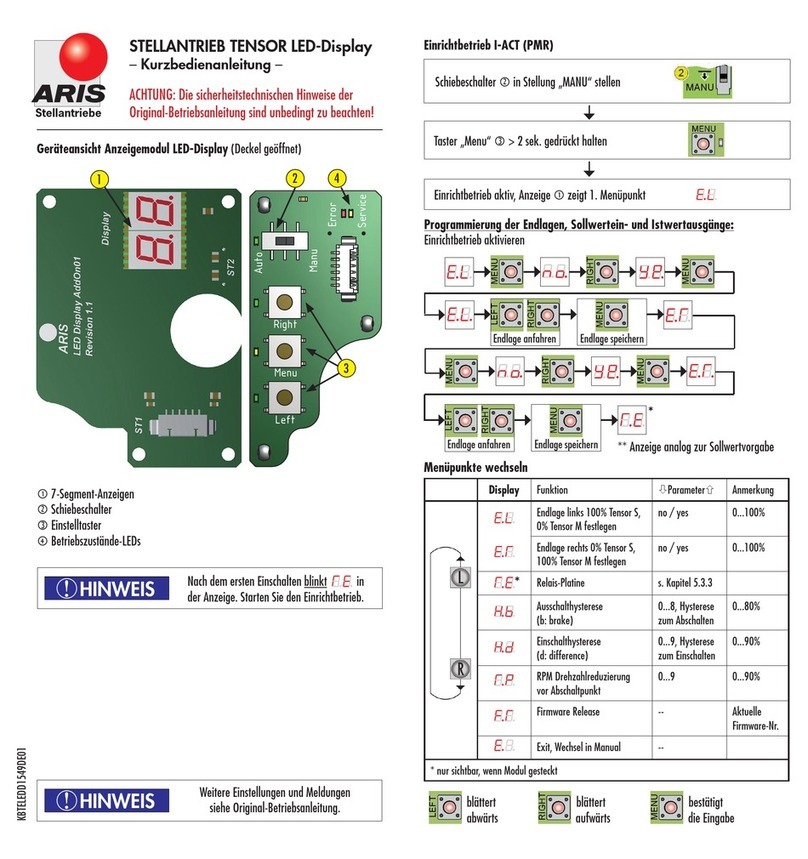

Initial operation........................................................................................................................................................................10

Electrical connection..................................................................................................................................................................10

Wiring diagram ........................................................................................................................................................................11

Operation of the actuators ........................................................................................................................................................11

Set up rotation direction............................................................................................................................................................ 11

Set up limit switches (Self-adjusting switch cam).........................................................................................................................12

Optional modules and extra features......................................................................................................................................... 12

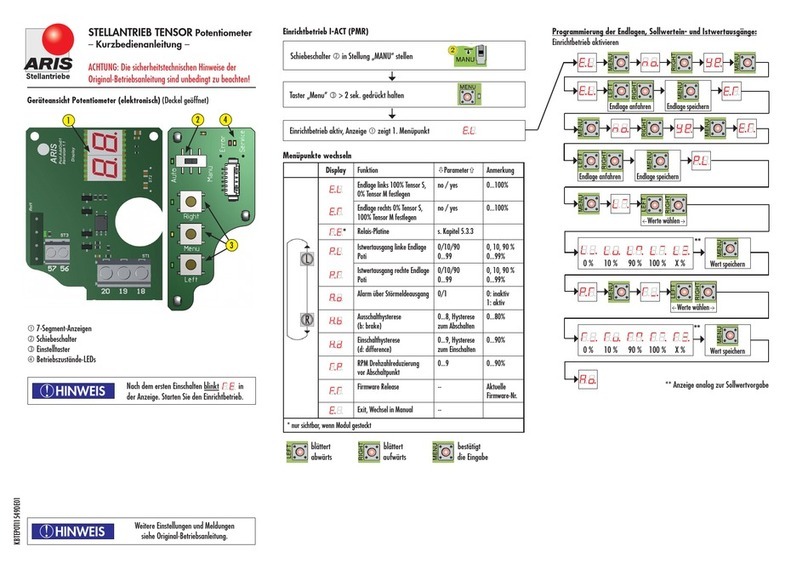

Potentiometer...........................................................................................................................................................................12

Potentiometer with approval acc. to DIN EN 12067-2 (TÜV-Poti).................................................................................................12

Additional limit switches (Self-adjusting switch cam)...................................................................................................................14

2-wire-current output 4-20 mA..................................................................................................................................................14

Mechanical position indicator.....................................................................................................................................................15

Service switch (230 V AC only)..................................................................................................................................................15

Heating resistant (230 V AC only)..............................................................................................................................................15

Single wire control (230 V AC only)...........................................................................................................................................16

Parallel relay (230 V AC only)................................................................................................................................................... 16

Power supply 24 V DC (Special edition)......................................................................................................................................17

Required customer information.................................................................................................................................................17

Extraordinary situations............................................................................................................................................................17

Troubleshooting and repair .......................................................................................................................................................18

Maintenance.............................................................................................................................................................................18

Service..................................................................................................................................................................................... 18

Accessories...............................................................................................................................................................................18

Spare parts...............................................................................................................................................................................18

ARIS Stellantriebe GmbH

53842 Troisdorf/Germany Fax: +49 2241 25186-99 www.stellantriebe.de