Inhaltsverzeichnis

1. Identication..............................................................................................................................................................3

1.1 Nameplate............................................................................................................................................................................................................................ 3

1.2 Guidelines and standards ...................................................................................................................................................................................................... 4

2. Safety information .....................................................................................................................................................4

2.1 Warnings.............................................................................................................................................................................................................................. 4

2.2 General safety advice............................................................................................................................................................................................................ 4

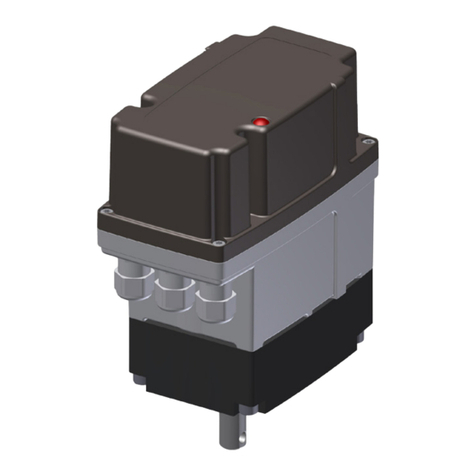

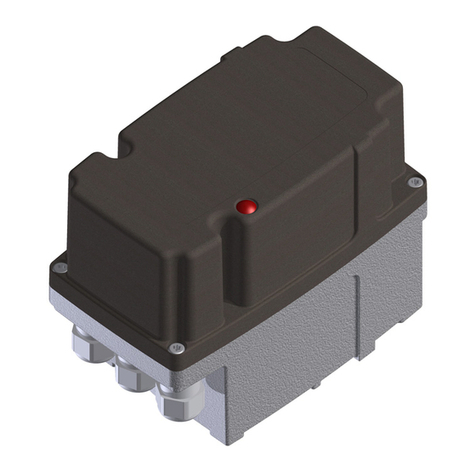

3. Technical specication .................................................................................................................................................5

3.1 Functions and application areas (Intended use)...................................................................................................................................................................... 5

3.2 Safe and accurate use........................................................................................................................................................................................................... 5

3.3 Dimensions........................................................................................................................................................................................................................... 6

3.4 Performance data............................................................................................................................................................................................................... 12

3.5 Expected lifespan and intended disposal .............................................................................................................................................................................. 12

4. Actuator setup for utilization ....................................................................................................................................13

4.1 Transport, (temporary) storage and downtimes.................................................................................................................................................................... 13

4.2 Packaging .......................................................................................................................................................................................................................... 13

4.3 Safe disposal of packaging.................................................................................................................................................................................................. 13

4.4 Installation and mounting ................................................................................................................................................................................................... 13

4.5 Initial operation.................................................................................................................................................................................................................. 14

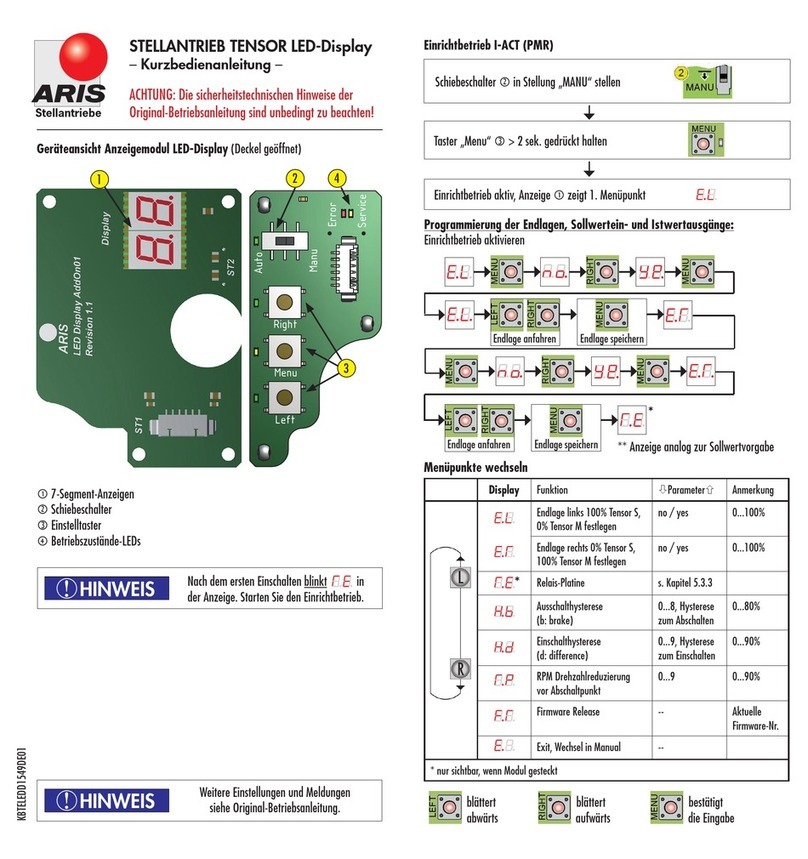

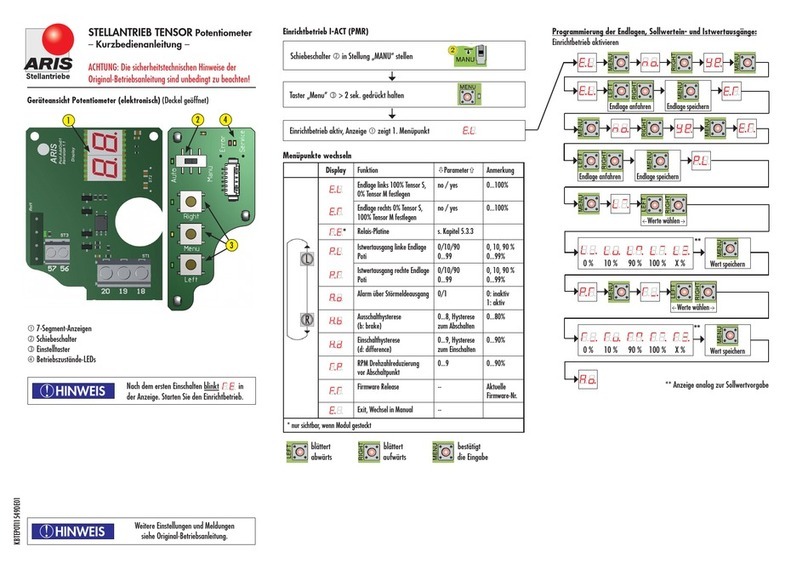

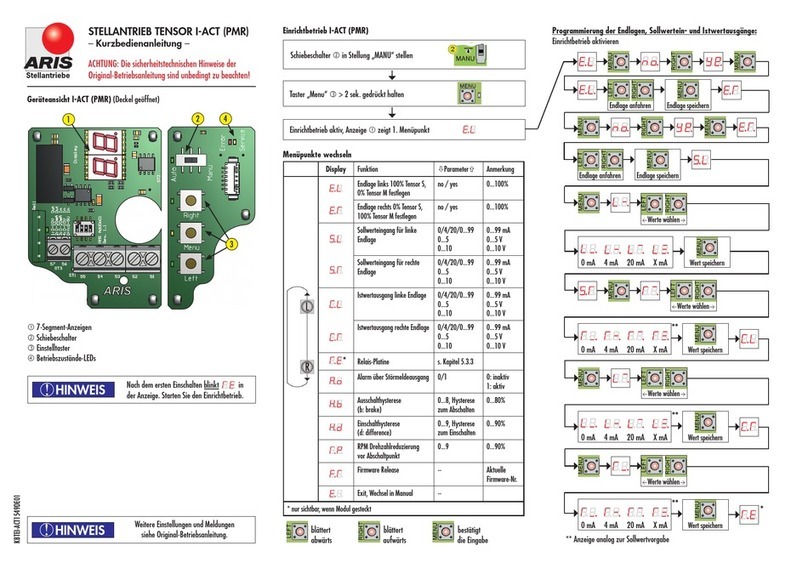

5. Actuator operation without modules (Standard) .........................................................................................................16

5.1 Operation........................................................................................................................................................................................................................... 16

6. Additional advice concerning the intended use in potentially explosive atmospheres of the zone 2 and 22 (Option).........33

6.1 Nameplate.......................................................................................................................................................................................................................... 33

6.2 Guidelines and standards .................................................................................................................................................................................................... 34

6.3 Technical specications........................................................................................................................................................................................................ 34

6.4 Performance data............................................................................................................................................................................................................... 35

7. Additional options ....................................................................................................................................................36

7.1 Internal manual override (mechanical)................................................................................................................................................................................ 36

7.2 Option hand wheel.............................................................................................................................................................................................................. 36

8. Parameter RESET......................................................................................................................................................36

9. Required customer information..................................................................................................................................37

9.1 Troubleshooting and repair.................................................................................................................................................................................................. 37

10. Maintenance ............................................................................................................................................................38

10.1 Service............................................................................................................................................................................................................................... 38

10.2 Accessories ......................................................................................................................................................................................................................... 38

10.3 Spare parts......................................................................................................................................................................................................................... 38