3

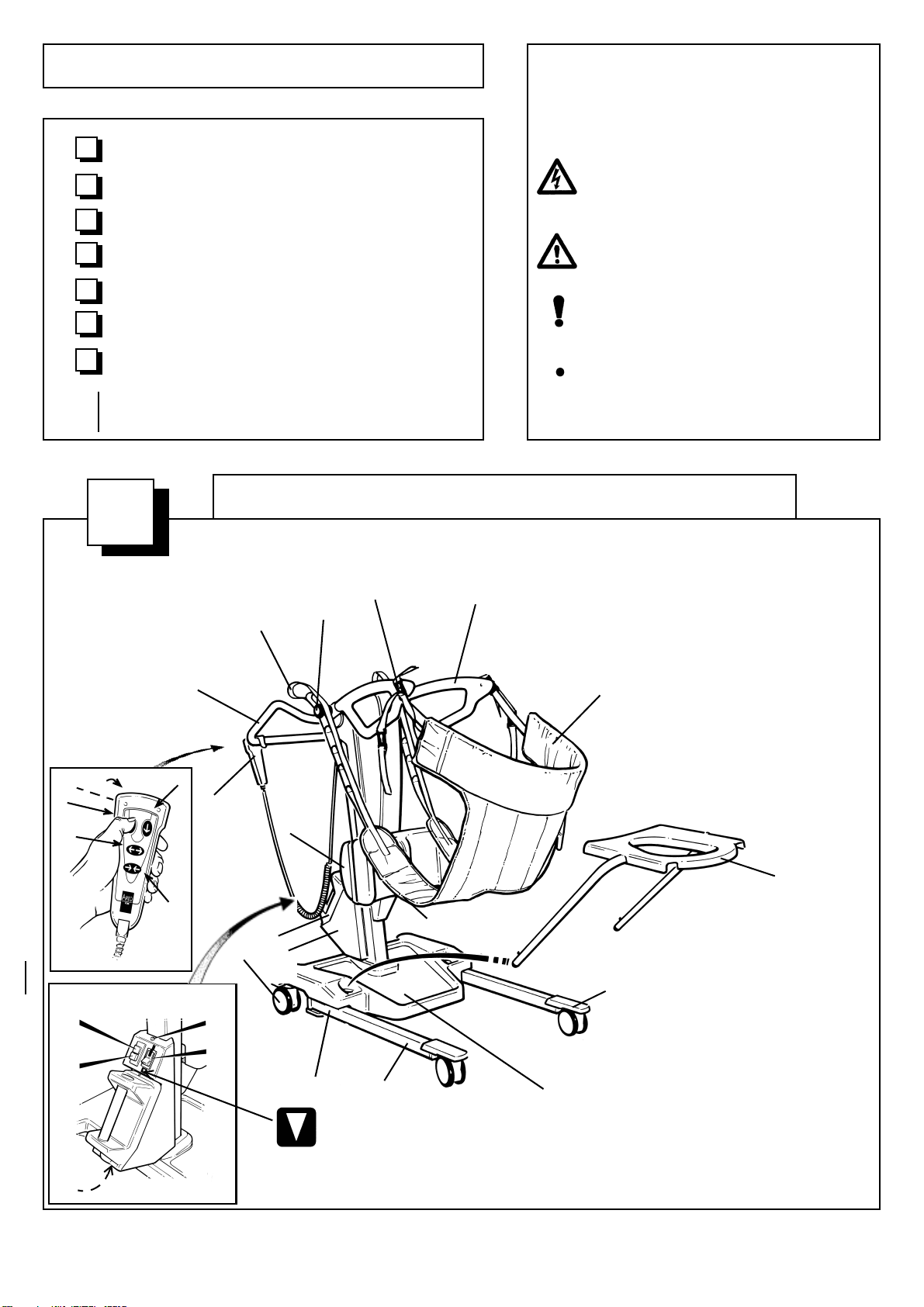

Note: On delivery of your hoist, check that the

usage indicator seal fixed across the emergency

lowering switch (see Fig. 1) is intact. If it is

broken, contact Arjo Ltd or their appointed

distributor, before using the hoist.

Before using your Sara 2000, familiarise

yourself with the various parts as illustrated in

figure 1, and thoroughly read and understand

these Operating Instructions.

The Sara 2000 is manufactured to a very high standard,

and primarily designed to assist patients when standing

and toileting, and for use as a short distance patient

transfer aid.

The Sara 2000 is designed for quick easy

transfers from one sitting position to another,

and to elevate a patient for toiletting,

repositioning, changing of incontinence pads,

wound dressings, standing practice etc. It is not

intended for long periods of suspension or

transportation.

This product has been designed and manufactured to

provide you with many years of trouble free use,

however, this product does contain components that

with regular use are subject to wear.

SOME OF THESE PARTS ARE

SAFETY CRITICAL TO THE OPERATION

OF THE HOIST AND WILL NEED

EXAMINING AND SERVICING ON A

REGULAR BASIS AND MUST BE

REPLACED WHEN NECESSARY. See also

“Care of your Sara 2000” section.

All references to the patient in these instructions

refer to the person being lifted, and references to the

attendant refer to the person who operates the hoist.

References to left and right of the hoist in these

instructions are as viewed from the rear of the

Sara 2000.

Use only Arjo slings that have been specifically

designed for the Sara 2000.

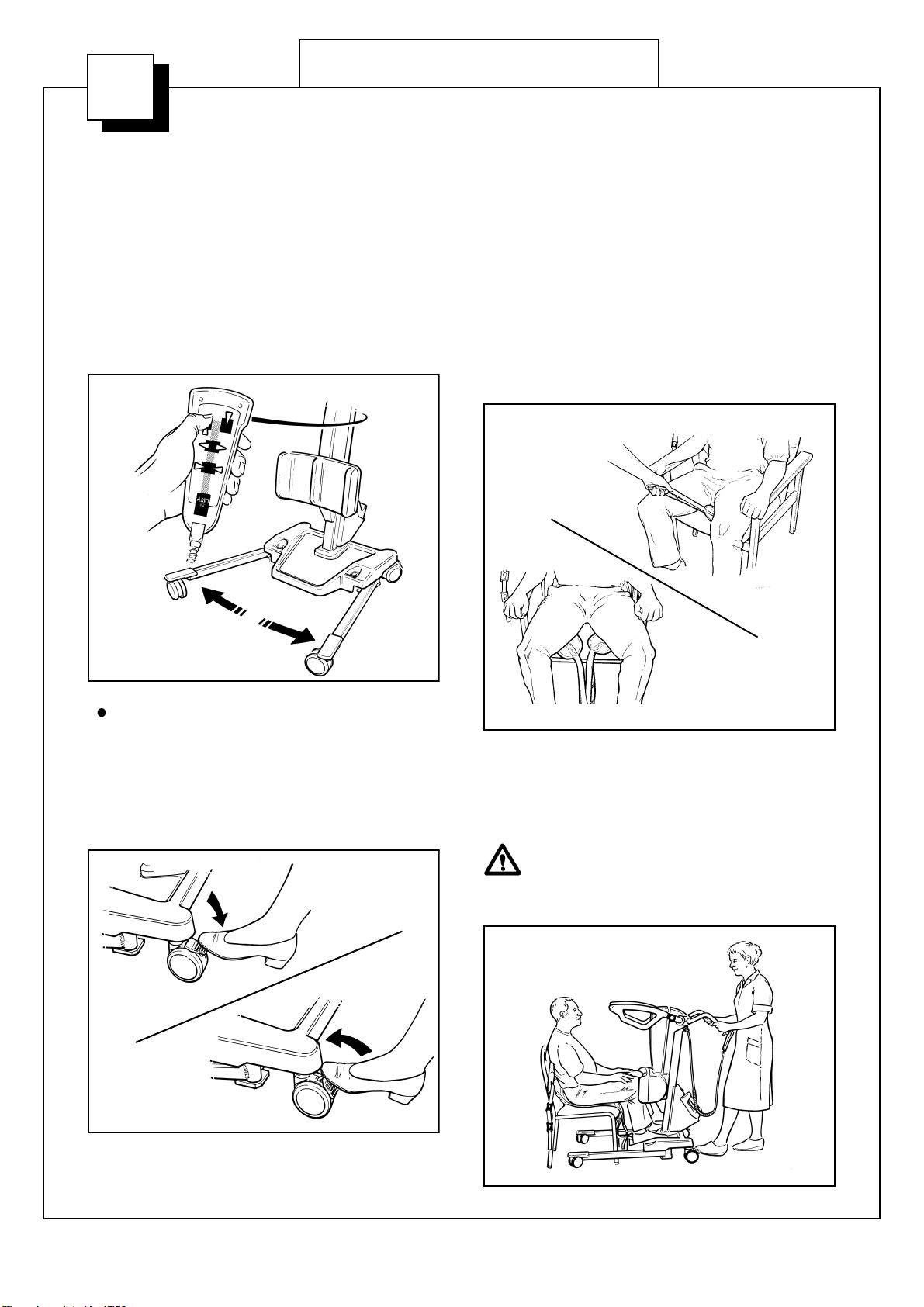

Two types of sling can be used with the Sara 2000.

•Standing Sling - a single loop sling, used for

supporting patients at the toilet, and to aid in

the standing process. This is a one size sling,

with variable adjustment using the different

attachment clips.

•Transfer Sling - a single loop sling with buttock

and leg support, used for easy and comfortable

transporting of patients over short distances.

The sling has variable adjustment using the

different attachment clips and leg strap loops,

(these being colour coded to relate them to the

size of patient to be lifted).

Commode Seat (accessory) - for toileting patients at

the chair side, or for patients who cannot be

transported. The assembly comprises an easy to fit

rigid commode seat, with removable commode pan.

It is available from Arjo as an accessory.

Do not overload the Sara 2000 with a weight in

excess of the approved lifting capacity of 180kg

(400lbs).

The commode and seat (accessory) has a

maximum weight limit of 160kg (350lbs) which

must not be exceeded, so allowance must be

made if using this facility.

The Sara 2000 may be used on gentle slopes

with caution.

Care should be taken when lifting detachable

components e.g. toilet seat, so as not to cause

personal injury.

Do not attempt to manually lift the complete

hoist.

A clinical assessment should be carried out by

a qualified nurse or therapist before lifting

patients who are non weight bearing. This

also applies to patients who have limited

shoulder movement or cannot hold on with

one or both hands.

Patients who have curvature of the spine, or

who are subject to muscle spasms may not be

suitable, and should be carefully assessed

before proceeding with the lift.

Although manufactured to a high standard

the Sara 2000 and accessories should not be

left for extended periods in humid or wet

areas.

Do not under any circumstances spray the

Sara 2000 or accessories (excluding slings)

with water e.g. under the shower.

Some information contained in these instructions may

become outdated, due to improvements made to this

product in the future. If you have any questions

regarding these instructions or your hoist, please

contact Arjo or their approved distributor.

Arjo’s policy is one of continuous development, and

therefore reserve the right to change specifications

without notice.

BIntroduction