Armedica AM-702 User manual

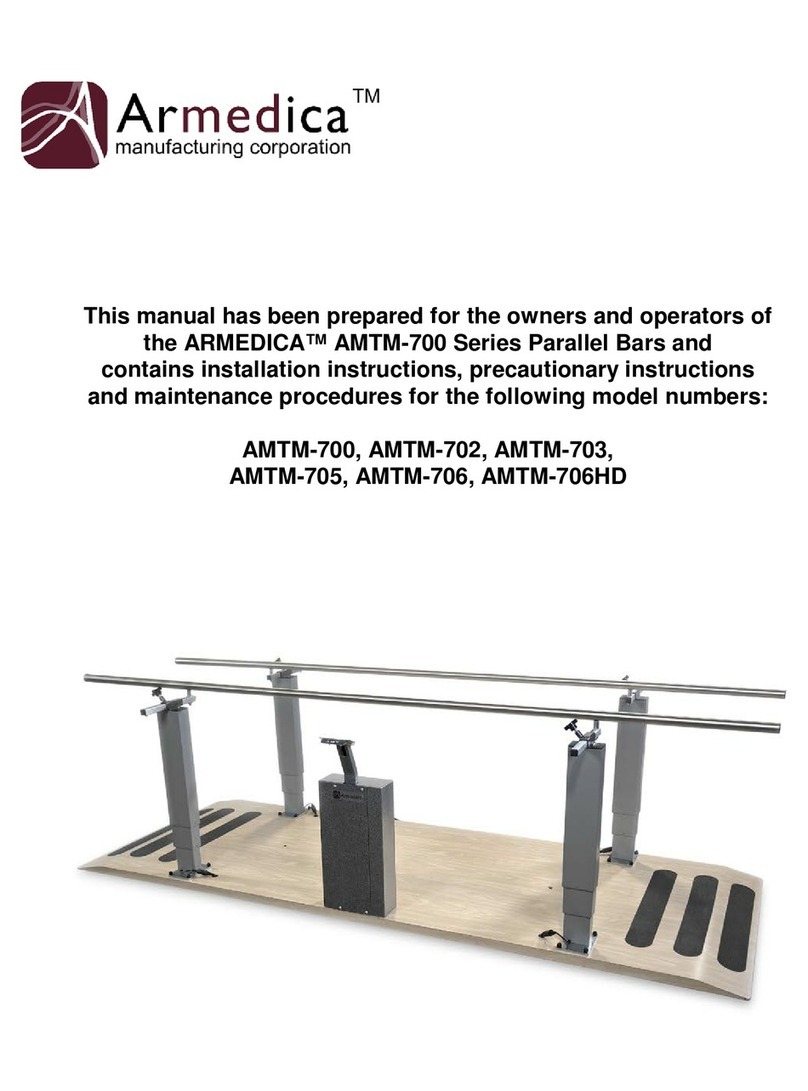

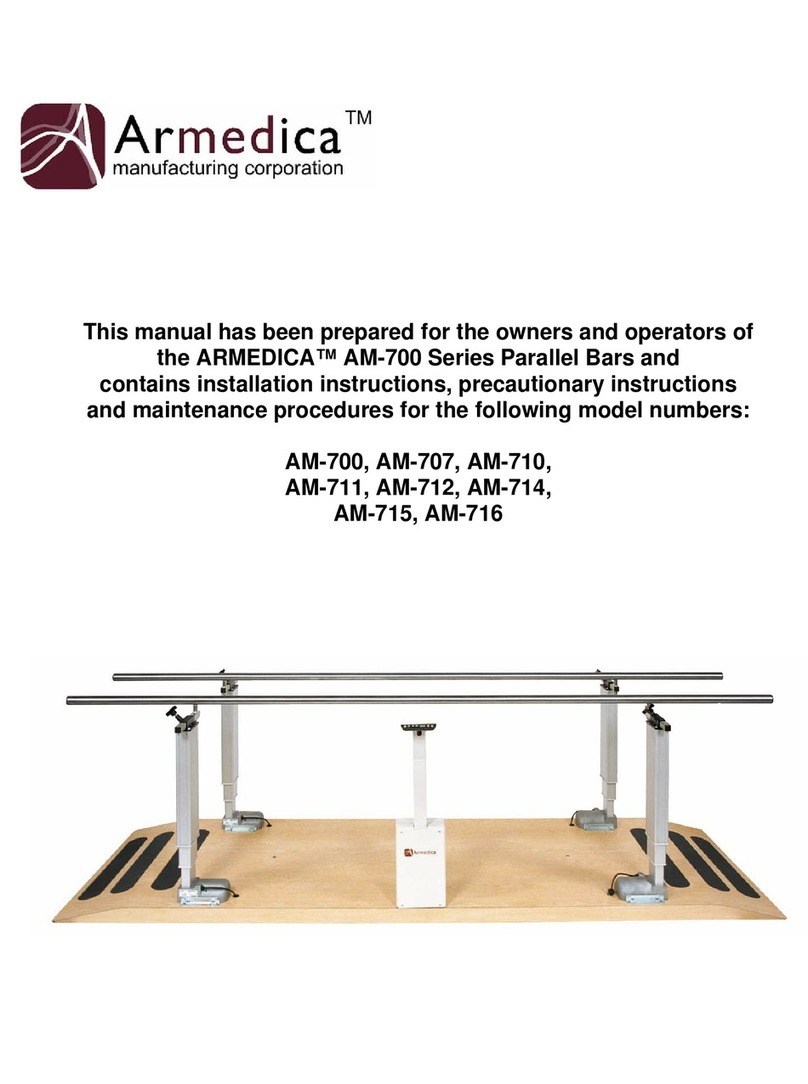

This manual has been prepared for the owners and operators of

the ARMEDICA™ AM-700 Series Parallel Bars and

contains installation instructions, precautionary instructions

and maintenance procedures for the following model numbers:

AM-700, AM-702, AM-703,

AM-705, AM-706, AM-706HD

This User's Manual is for the following AM-700 series Parallel platforms only

AM-700 - Electric platform mount 10'x43"

AM-702 - Electric platform mount 7'x43"

AM-703 - Electric platform mount 15'x43"

AM-705 - Electric bariatric platform mount 10'x49-1/2"

AM-706 - Electric bariatric platform mount 10'X49-1/2"

AM-706HD - Electric bariatric platform mount 10'x49-1/2" with 11GA. hand rails

Table of Contents

Models covered in manual and table of contents 2

Symbols and Indicators 3

Definitions 4

Assembly and Installation 6

Operating instructions 9

Maintenance 10

Cleaning 11

Technical specifications 12

Parts list and Drawings 13

Maintenance Log 23

Warranty information 24

IMPORTANT: Do not use this manual to reference instructions, requirements or

specifications for any product other than those listed in this manual.

Equipment damage, void of warranty and personal injury may occur.

WARNING: Read and understand this user's manual before installing or using this

equipment.

Failure to follow operating and maintenance instructions could result in equipment

damage or personal injury.

SYMBOLS and INDICATORS

WARNING: Follow safe lifting procedures and precautions.

ATTENTION: Important information or instructions.

Type B Applied part: An Applied Part complying with the specified requirements to

provide protection against electric shock, particularly regarding allowable patient

leakage current and patient auxiliary current.

WARNING: Identifies electrical shock hazard.

This platform is equipped with a protective earth ground. This device may only be

connected to a power source with a protectively earthed ground.

WARNING: Read and understand the operating instructions listed in this manual

before installing or using this equipment.

Failure to follow manufacturer's operating instructions could result in equipment

damage or personal injury.

Alternating Current

2

DEFINITIONS

The AM-700 Series Electric Parallel Bars are a Class 1 medical device in respect

to the use of an earthed ground as a means of protection against electric shock.

Intended use: The AM-700 Series Electric Parallel Bars is intended for medical

rehabilitation purposes and, to be used in conjunction with other forms of

exercise, as a stability aid in standing, walking and balance exercises.

Patient: Any person cleared by a doctor or physical therapist currently using this

device as an exercise platform under the direction and supervision of a qualified

operator.

Operator: Any person/persons who is a professionally trained and certified

physical therapist and authorized by the consumer or responsible organization to

operate this platform. Specific instructions for operation of the AM-700 series

can be found in this manual. If further training on the operation of the AM-700 is

required, it is available by contacting Armedica Mfg. customer service.

Service Technician: Any person/persons authorized by Armedica Manufacturing

to perform service, component replacement or repair to the AM-700 Series

Electric Parallel Bars.

CAUTION: A patient is not intended to operate this device in any

way. The AM-700 series Electric Parallel Bars shall be operated

by trained, qualified and authorized personnel ONLY.

CAUTION: Using this device in a manor inconsistent with its

labeling will void warranty and, damage to device or personal

injury may occur.

CAUTION: This device is not suitable for use in an oxygen rich

environment or in the presence of flammable anesthetics. Fire or

explosion may occur.

3

DEFINITIONS CONTINUED

Duty Cycle: The ratio of time the device can be in a state of continuous actuation

(moving) and rest. Noted in units of minutes as ON/OFF. The Duty Cycle of this

device is rated for 1(one) minute on / 9(nine) minutes off.

Electrical power source: This platform is intended to be connected to an external

120V , 8 Amp (peak), 60Hz electrical power source.

Applied part: An applied part is one specifically intended to come into direct

contact with patient during normal use. This includes Armedica part #'s 18628,

28320, 18627, 14601, 14605, 14609, 14610 and 14615 only. Applied parts are

identified, either in this manual or directly on the part, with this symbol .

Accessible Part: An Accessible Part is any part that the patient or operator may

come into direct contact with, either intentional or unintentionally, but direct

contact is not required for normal operation.

Operator Interface: The point in which the operator will input data, via momentary

push button, for actuation, memory function and device control.

WARNING: To avoid risk of electrical shock, this device must

only be connected to a supply mains with protective earth

ground.

4

AM SERIES ELECTRIC PARALLEL BARS

ELECTRIC PARALLEL BARS INSTALLATION

ALL MODELS

1. Remove platform (item # 1, 46, 47 or 51) from crate using handles attached to mounting

brackets. Set the platform on firm level floor.

For 2-piece split platforms, set both pieces on side against a solid surface while installing

connecting plates (50). Align the 2 pieces and firmly hold together. Using screws (49),

install all connecting plates in recessed pockets. After all, connecting plates have been

installed, place platform on floor as directed in step 1.

2. Place the four upright columns (13) between the brackets on the platform according to

letter designations and tighten the mounting bolts (10) securely.

3. Install the hand rails (30, 44 or 45) onto the adjustment tubes (4) using spacer (31),

washers x2 (32), and lock nut (35); tighten the lock nut (35), sufficiently, to eliminate any

play but not so tight that they will not pivot when adjusting the width. When necessary,

adjust the width according to the operating instructions.

4. Remove the cover plate from box (23) to allow access to inside of control stand (20).

Using nuts (21), mount the control stand (20) to the platform, threading AC mains cable, 4

protective earth ground wires (green with yellow), and connector cables (36, 37 and 42)

through appropriate holes. Ensure all protective earth grounds are secured on the bolt pin

with paint removed.

5. With screws (26) and cover plate (24) removed, connect the controller (22) per the

following instructions.

WARNING: Read and understand this operator’s manual before

installing or using this equipment.

Failure to follow operating and maintenance instructions could result

in equipment damage or personal injury.

WARNING: 4 people are required to move this equipment.

This unit weighs in excess of 500lbs/1100kg. Failure to follow safe

lifting instructions can result in serious personal injury and/or damage

to equipment.

CAUTION: There are no contradictions associated with this

device. The emissions characteristics of this device make it

suitable for use in industrial areas and hospitals.

CAUTION: Do not lift or support by end ramps or columns. Damage t

or serious personal injury may occur

5

SCU CONTROLLER

1. SCU CONTROLLER

2. AC MAINS PORT

3. SWITCH PORT

4. PROTECTIVE EARTH

TERMINAL

5. MOTOR PORT M1

6. MOTOR PORT M2

7. MOTOR PORT M3

8. MOTOR PORT M4

CAUTION: All cables must be fully inserted into their appropriate

receptacles on control box and columns. Failure to do so may cause

unit malfunction and/or permanent damage to equipment.

WARNING: Dangerous voltage present.

Do not connect this unit to a power source before reading these

instructions. Damage to equipment and/or electrical shock may

occur.

WARNING:

This device may only be used in a professional healthcare

facility where operators with professional medical training are

continuously available when patients are present.

WARNING: Do not adjust or operate this device while patient is on or

using this device. Serious personal injury and/or damage to

equipment may occur.

1

2

3

4

5

6

7

8

6

CABLE CONNECTIONS

•Connect the four cables (36) and (37) (DIN8 connectors) to the appropriate column (13).

•Remove cover from the lower section of the SCU controller by rotating the lock screw,

located on the front of the cover, to the “UNLOCK” position. Slide cover down to remove.

•Connect the four cables (36) and (37) (DIN8 connectors) to corresponding SCU controller

motor ports M1, M2, M3 and M4 (AS LABLED)

•Verify that the control switch (27) cable with a blue DIN7 socket marked with a blue “HS” is

securely connected in the switch port

•Securely connect the AC mains cable (42) into the AC mains port of the SCU controller.

•Verify that the required supply voltage indicated in this manual and on the name plate

corresponds with the supply voltage of the electrical outlet and connect the unit to the

electrical outlet. *See Technical Data section for a full list of operating conditions and

requirements.*

CAUTION: This device is rated for 120 volts

60Htz, 6.5Amps/8Amps peak. Protective

earth ground required.

ATTENTION: Allow 10 seconds, after

connecting to power supply, for system to

fully initialize and display reads “028”before

attempting any operations. See figure

below.

7

ELECTRIC PARALLEL BARS OPERATING INSTRUCTIONS

ALL MODELS INTENDED POSITIONS

This unit has been initialized by Armedica Manufacturing Corp. prior to shipment and

should not need to be synchronized again unless a column or control box is replaced.

If Synchronization becomes necessary, follow these steps:

INITIAL RESET FOR MOTORS

•After you have connected the control units to the power supply for the first time, the

network is addressed, and motors must be synced. This is indicated by "---" remaining on

the display after approximately 10 seconds.

•Press and hold 1+2+UP BUTTON for 5-10 seconds then you will hear a audible click,

then beeps. Release buttons, beep stops.

•Press and HOLD the down ARROW key. All 4 columns should lower at a reduced speed.

Continue to hold the key until the columns reach their lowest point and, you hear an

audible click. Wait three seconds and display should show the current height.

SETTING THE PARALLEL BAR HEIGHT

•Press the up arrow to raise the parallel bars.

•Press the down arrow to lower the parallel bars.

•The current height of the bars appears (in inches) on the display.

SAVING THE MEMORY POSITIONS

This function makes it possible to save a predetermined height setting. Four different heights

may be saved. These saved positions can be used later.

•Adjust the bars to desired height by using the UP or Down arrow keys.

•Press the green memory key (S) and release. Press the desired memory key (1, 2, 3 or 4).

An audible click signals the position is now saved to that number.

WARNING: Ensure platform is clear and, there are no obstructions

under the handrails before actuating the columns to adjust height.

Serious personal injury and/or damage to equipment may occur.

Operator position

Patient position

8

USING THE MEMORY POSITIONS

•While holding down the desired memory position button, the bars will move toward the

predefined position and stop.

ADJUSTING THE WIDTH OF THE PARALLEL BARS

•Turn hand knobs, on top of each column, to release adjusting tubes and set to desired

width.

•

Make sure adjusting tube knobs are securely tightened before use.

MAINTENANCE

ARMEDICA™ Manufacturing thoroughly inspects and tests each unit to ensure that it

meets all ARMEDICA™ quality standards before it leaves the facility. To ensure the

longevity of your device, routine maintenance should be followed.

AFTER FIRST 40 HOURS OF SERVICE

Physically inspect all fasteners and hardware are properly secured

DAILY / Pre-USE

The operator should visually inspect the unit prior to each use for;

Foreign objects that may interfere with operation or create a hazard to patient

Signs of damage to unit and power cord

All hardware (nuts, bolts, etc.) is present and properly secured

All adjustments are secure

Unit functions properly

CLEANING

Use towel dampened with mild soap and water. Wipe down to remove dust, dirt and spills.

Wipe with dry towel to remove moisture

Laminated platform

Painted, plated and plastic surfaces

Use a commercial brand stainless steel cleaner to remove dirt and oil from hand rails

The laminated platform and painted or plated components should be cleaned with a

commercial disinfectant and wiped with a dry cloth to remove any biological contamination

when necessary.

CAUTION: Failure to follow recommended maintenance instructions

may cause damage to equipment, personal injury and void warranty.

WARNING: This unit is not rated for wash down, it should not be

exposed to standing or quantities of liquid.

Do not clean any electronic device with water. Electrical shock and/or

damage to electronics may occur.

9

TROUBLE SHOOTING

In the event it becomes necessary to replace the control box or a column on the AM-700 series,

disconnect power prior to removal, and make certain the plugs are completely inserted into the

sockets prior to reconnecting power.

ELECTRIC POWERED COLUMNS DO NOT WORK.

A. Verify that proper voltage at electrical outlet and cord is plugged in.

B. Verify all cables inside the control stand and motor columns are securely plugged into their

proper receptacles.

C. Verify the hand switch cable is securely plugged into the proper control unit.

If problem still occurs, or columns become unsynchronized, please contact Armedica

Manufacturing Customer Service.

ATTENTION:

The AC Mains Cable serves as the

EMERGENCY DISCONNECT DEVICE

Do not position this device in a manner that would make it difficult to

reach the AC mains supply cable. In the event of an emergency,

unplug the AC Mains Cable from the external power supply.

WARNING: Disconnect main power to unit before opening control

stand and checking cables. Electrical shock and/or damage to

electronics may occur.

CAUTION: Service to controls and column motors is to be done by

the manufacturer only. In the event of a column motor or control unit

failure, all 4 columns and control unit must be returned to Armedica

Manufacturing Corp.

WARNING: Do not alter or modify this device in any way. Altering

this device will void all warranties. Serious personal injury and/or

damage to equipment may occur.

WARNING: Use only replacement parts approved by Armedica

Manufacturing. Failure to do so could result in damage to device,

increased emissions, immunity/susceptibility to such and serious

injury. A list of specific authorized replacement parts, including

cables and other critical components, is provided on page 15 of this

manual.

10

TECHNICAL SPECIFICATIONS

ENVIROMENTAL CONDITIONS

Operating/storage temp. 5°C – 40°C / 41°F – 104°F

Humidity: 5% to 85%

Pressure/altitude: 700hPa to 1060hPa

GENERAL SPECIFICATIONS

Manufactured and assembled by

Armedica Manufacturing Corp.

Greenwood, Arkansas, USA

Tel.: (479) 996-2612

Static & Dynamic load capacity

Max 500Lbs/227Kgs per bar, not exceeding 500Lbs/227Kgs total combined load.

ELECTRICAL SPECIFICATIONS

Main input power requirements 120VAC 60Hz

Current 6.5Amps / 8Amps (peak)

Secondary output power 24VDC / 360V/A

Duty cycle 1min. on / 9min. off

Model SCU56-003230-000

Manufactured by:

SKF Actuation Systems

Oristalstrasse 97

CH-4410 Liestal

Tel.: +41/61/925 41 41

Email: actuators.switzer[email protected]

CAUTION: Do not exceed Maximum load capacity. Damage to unit

and/or serious injury may occur. This device is not rated for a

dynamic(moving) load. Do not use as a patient lift.

CAUTION: Do not throw in trash. Expected service life of this device

is approximately 10 years. Dispose of this device in accordance

with local, state and national environmental regulations. Failure to

do so may constitute a criminal act.

11

ITEM NO. PART NO. DESCRIPTION QUANTITY

MODEL NUMBERS

700 702 703 705 706 706HD

1 14601 BD PLL COLMN PLATFORM LAMNTD

1N/A N/A N/A N/A N/A

2 28156 PLATE 1/4x4-3/4x6-1/2 PLL COLMN MNT PLTD 44444 4

3 03021 SCREW TAPTITE M6X2

5

16 16 16 16 16 16

4 11601 TUBE 1x1x14GAx13 PLL RAIL ATTAC

H

44444 4

5 02146 SPACER 5/16 X 3/16 ID x 1/2 OD 44444 4

6 02093 NUT NYLOCK 8-32 44444 4

7 13601 ROD 1/2 DIAx.75 PLUNGER 44444 4

8 03071 KNOB W/STEM 2-1/4x3/8-16x1 44444 4

9 02033 NUT HEX M8-1.25Z 16 16 16 16 16 16

10 02031 SCREW HEX HD 8MM-1.25x14Z 16 16 16 16 16 16

11 03076 CAP PLAS BLK 5/16 HEX DOM

E

16 16 16 16 16 16

12 18593 BRKT PLL RAIL ADJ RT PLT

D

22222 2

13 03181 TMD PLL COLUMN ONLY 44444 4

14 02105 NUT NYLOCK 5/16-18 16 16 16 16 16 16

15 28042 BRKT PLL COLUMN MNT W/HANDLEPLTD 4 4444 4

16 12633 ANG 1x1x6-1/4 PLL CLMN MNT PLTD 44444 4

17 18665 BUSH W/WASHER PLL PIN GUIDEPLTD 2 2222 2

18 02063 SCREW HX WASHER HD #10x3/

4

38 38 38 38 38 38

19 28040 BRKT PLL PLTFRM CONTROL STANDMNT 1 1111 1

20 18672 TUBE PLL CTRL STAND S/

A

11111 1

21 02100 NUT NYLOCK 1/4-20 44444 4

22 03556 CONTROL SCU PLL 11111 1

23 03078 BOX 4-5/16x17x14GA SHT MTL PLL 11111 1

24 03078 PLATE 8-1/4x16-15/16x14GA COVER SKF PLL 1 1111 1

25 03080 RIV NUT 1/4-20 ALUMINUM 14GA 44444 4

26 02538 SCREW BTN HD SOC 1/4-20x3/4 44444 4

27 03183 SWITCH PLL TMD CONTRO

L

11111 1

28 02040 NUT HX 5-40 MACH SCR

W

33333 3

29 18598 BRKT PLL RAIL ADJUST LEFT PLT

D

22222 2

30 18628 TUBE STAINLESS PLL RAIL S/A

2N/A N/A 2 2 2

31 13056 BUSHING 1/2IDx3/4ODx1-1/8 CNTRL BUSH 4 4444 4

32 02165 WASHER NYLON 1/2 I

D

88888 8

33 03010 PLUG 1x1x14G

A

88888 8

34 03014 PLUG RD 1"ODx14-20 GA BLK 44444 4

35 02095 NUT NYLOCK JAM 1/2-13 4444 4 4

36 03184 CABLE TMD CONNECT LONG 8F

T

22222 2

37 03185 CABLE TMD CONNECT SHORT 4'-10

"

22222 2

38 02148 BUSHING INSUL NYLON PLL 4444 4 4

39 03364 LD SWITCH ADAPTE

R

11111 1

40 02107 SCREW PAN HD PHIL 8-32x3/4" 44444 4

42 03365 CBL 3.6M MED UL PWR CORD SCU 1111 1 1

43 02201 CLAMP CABLE 1/4 WHIT

E

30 30 30 30 30 30

44 18627 TUBE STAINLESS 15' PLL RAIL S/A N/A N/A 2 N/A N/A N/A

45 11607 TUBE SS PLL 1-1/2 DIAx14GAx7'-6" N/

A

2N/

A

N/

A

N/

A

N/

A

46 14609 BD PLL 7FT COLMN PLTFRM LAMNT N/A 1 N/A N/A N/A N/A

47 14610 BD PLL 15' SPLIT PLATFORM LAMN

T

N/

A

N/

A

1N/

A

N/

A

N/

A

48 02200 CLAMP CABLE 3/16 BLACK

N/A N/

A

12 N/

A

N/

A

N/

A

49 02695 SCREW #14x1 FLT HD PHIL WD N/A N/

A

16 20 20 20

50 12609 PLT 1/4x2x8 PLL SPLIT PLTFRM PNTD N/A N/

A

455 5

51 14615 BD PLL 10' PLTFRM BARIAT SPLIT W/E

C

N/A N/

A

N/

A

N/

A

11

52 14605 BD PLL COLMN PLATFORM BARIATRI

C

N/

A

N/

A

N/

A

1N/

A

N/

A

53 28320 TUBE STNLSS PLL 10' HD N/

A

N/

A

N/

A

N/

A

N/

A

2

54 02681 SCREW PAN HD PHIL 10-32x3/4 4 4 4 4 4 4

55 02144 WASHER FLAT #10

4444 4 4

56 03554 WIRE 74" PE GRND PLL COLUMN ASM 2 2 2 2 2 2

57 03555 WIRE 48" PE GRND PLL COLUMN AS

M

2222 2 2

58 02078 SCREW PAN HD PHIL 10-32x3/

8

4444 4 4

59 02493 TERM RING INSUL #10 STUD 22-18 AWG 4444 4 4

12

HEIGHT ADJUSTMENT

27" MINIMUM

TO

54" MAXIMUM

PATIENT

HAND RAIL

120" PLATFORM LENGTH

VARIES BY MODEL

43"

PLATFORM WIDTH

VARIES BY MODEL

WIDTH ADJUSTMENT

30" MAXIMUM

TO

14" MINIMUM

WIDTH ADJUSTMENT

LOCKING KNOB

OPERATOR INTERFACE

SWITCH

AM-700 SERIES

DIMENSIONS & ADJUSTMENT SPECIFICATIONS

13

29

10

14

11

15 36

8

4

33

3

6

5

40

21

20

1

30

35 32

31

34

12

29

44 45 53

46

47

51

52

37

16

7

AM-700 SERIES

ELECTRIC PARALLEL BARS

13

14

19

18

17

43

57

56 59

58

AM-700 SERIES

ELECTRIC PARALLEL BARS

BOTTOM VIEW

15

23

20

27

55

54

22

24

26

39

42

AM-700 SERIES

ELECTRIC CONTROL STAND

28

16

50

49

51

47

AM SERIES

SPLIT PLATFORMS

WITH END CONTROLS

ITEM NO.

PART NUMBER

DESCRIPTION

QTY.

51

EC14605Bs

BD PLY PLL CLMN BARIATRIC PLTFRM

1

50

12608A

PLT 1/4x2x8 PLL SPLIT PLTFRM CONN

PNTD

5

49

02695A

SCREW #14x1 FLT HD PHIL WD

20

4

18671E_cmplt

TUBE PLL CTRL STAND S/A

1

5

03183A

SWITCH PLL TMD CONTROL

1

6

28155A

PLATE 1/4x4-3/4x6-1/2 PLL COLMN

MNT PNTD

4

7

03021A

SCREW TAPTITE M6X25

4

8

11601C

TUBE 1x1x14GAx13 PLL RAIL ATTACH

4

9

02146A

SPACER 5/16 X 3/16 ID x 1/2 OD

4

10

02007A

SCREW HX WASHER HD #8x3/4

4

11

13601A

ROD 1/2 DIAx.75 PLUNGER

3

12

03071A

KNOB W/STEM 2-1/4x3/8-16x1

4

13

02033A

NUT HEX M8-1.25Z

16

14

02031A

SCREW HEX HD 8MM-1.25x14Z

6

15

03076A

CAP PLAS BLK 5/16 HEX DOME

15

16

18592A

BRKT PLL RAIL ADJ RT PNTD BLACK

2

17

03181A

TMD PLL COLUMN ONLY

4

18

02105A

NUT NYLOCK 5/16-18

16

19

28041A

BRKT PLL COLUMN MNT W/HANDLE

PLTD

4

20

12632B

ANG 1x1x6-1/4 PLL CLMN MNT PNTD

4

21

18664B

BUSH W/WASHER PLL PIN GUIDE

PLTD

2

22

02063A

SCREW HX WASHER HD #10x3/4

10

23

18597A

BRKT PLL RAIL ADJUST LEFT PNTD

BLACK

2

24

18628A

TUBE STAINLESS PLL RAIL S/A

2

25

13056A

BUSHING 1/2IDx3/4ODx1-1/8 CNTRL

BUSH

4

26

02165A

WASHER NYLON 1/2 ID

8

27

03010A

PLUG 1x1x14GA

8

28

03014A

PLUG RD 1"ODx14-20 GA BLK

4

29

02095A

NUT NYLOCK JAM 1/2-13

4

30

03184A

CABLE TMD CONNECT LONG 8FT

2

31

03185A

CABLE TMD CONNECT SHORT 4'-10"

2

32

02148A

BUSHING INSUL NYLON PLL

4

33

02201A

CLAMP CABLE 1/4 WHITE

4

17

47

SPLIT PLATFORMS WITH

END CONTROL

51

5049

18

AM-714

ABDUCTION BOARD

4

3

2

1

1

2

AM-715

BALANCE BEAM

ITEM NO.

PART NUMBER

DESCRIPTION

QTY.

1

14603A

BD PLL ABDUCTION 3/4X5X94

1

2 18667

BRKT YOKE PLL BD PIN PLTD

2

3 02044

SCREW HX HD CAP 1/4-20x1-1/4

2

4 02084

NUT NYLOCK JAM 1/4-20

2

ITEM NO.

PART

NUMBER

DESCRIPTION

QTY.

1

14604A

BD PLL BAL BEAM 2-1/2X5X80

1

2

13003A

SCREW 3/-16x3 MODIFIED 2-3/8 PIN

2

19

This manual suits for next models

6

Table of contents

Other Armedica Medical Equipment manuals

Armedica

Armedica AM Series User manual

Armedica

Armedica AM Series User manual

Armedica

Armedica AM-SX Series User manual

Armedica

Armedica AMTM-700 Series User manual

Armedica

Armedica AM-SX Series User manual

Armedica

Armedica AM-700 Series User manual

Armedica

Armedica AM-BA Series User manual

Armedica

Armedica AM-BA Series User manual

Popular Medical Equipment manuals by other brands

Getinge

Getinge Arjohuntleigh Nimbus 3 Professional Instructions for use

Mettler Electronics

Mettler Electronics Sonicator 730 Maintenance manual

Pressalit Care

Pressalit Care R1100 Mounting instruction

Denas MS

Denas MS DENAS-T operating manual

bort medical

bort medical ActiveColor quick guide

AccuVein

AccuVein AV400 user manual