66

66

6

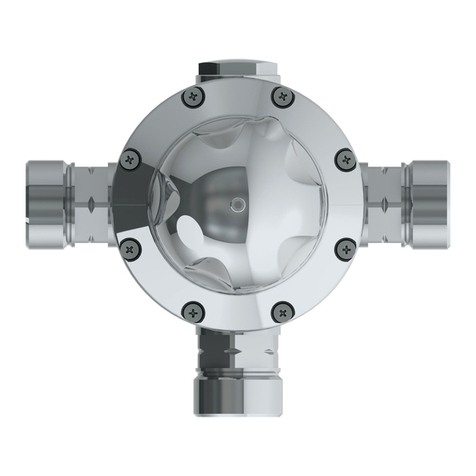

Troubleshooting Guide and Disassembly Instructions

Troubleshooting Guide

CapCap

CapCap

Cap

Lock nutLock nut

Lock nutLock nut

Lock nut

Top PlateTop Plate

Top PlateTop Plate

Top Plate

2121

2121

21

Bottom PlateBottom Plate

Bottom PlateBottom Plate

Bottom Plate

1515

1515

15

1414

1414

14 Spring RetainerSpring Retainer

Spring RetainerSpring Retainer

Spring Retainer

1313

1313

13

2828

2828

28

2323

2323

23

BoltBolt

BoltBolt

Bolt

tool with a sharp edge applied to the notch of the

diaphragm.

3. Take out the pilot valve seat (11) by removing the

pilot valve seat from the center of the top cover (3) by

using a ring spanner or socket wrench. Then pick out

the pilot valve (10) and the spring (20).

Piston Disassembly

1. Remove the hexagon bolts (23) from the top cover (3),

and the top cover from the body, and pull out the

piston (8) and the cylinder (9).

Main Valve Disassembly

1. Remove the hexagon bolts (23) from the bottom cover

(2), and the bottom cover from the body, and take out

the spring (19) and the main valve (6).

Notes to Re-assemble

1. Make sure that the main valve, the valve seat, the pilot

valve and the pilot valve seat have no flaws. Even a

small flaw on the seats may cause leakage.

2. Make sure that sliding movement is smooth.

3. Be sure to replace all gaskets and diaphragms with

new ones. (If cutting a new gasket (28) or (26) make

sure it is the same thickness as the old gasket).

55

55

5

Adjusting ScrewAdjusting Screw

Adjusting ScrewAdjusting Screw

Adjusting Screw

1717

1717

17

1818

1818

18

44

44

4

Spring HousingSpring Housing

Spring HousingSpring Housing

Spring Housing

16

Adjusting SpringAdjusting Spring

Adjusting SpringAdjusting Spring

Adjusting Spring

DiaphragmDiaphragm

DiaphragmDiaphragm

Diaphragm

GasketGasket

GasketGasket

Gasket

1111

1111

11 Pilot Valve SeatPilot Valve Seat

Pilot Valve SeatPilot Valve Seat

Pilot Valve Seat

3333

3333

33 Pilot Valve RingPilot Valve Ring

Pilot Valve RingPilot Valve Ring

Pilot Valve Ring

1010

1010

10 Pilot ValvePilot Valve

Pilot ValvePilot Valve

Pilot Valve

2020

2020

20 SpringSpring

SpringSpring

Spring

33

33

3

Top CoverTop Cover

Top CoverTop Cover

Top Cover

1212

1212

12

StrainerStrainer

StrainerStrainer

Strainer

GasketGasket

GasketGasket

Gasket2929

2929

29

2525

2525

25

3232

3232

32

3434

3434

34

GuideGuide

GuideGuide

Guide

PipePipe

PipePipe

Pipe

GasketGasket

GasketGasket

Gasket

CapCap

CapCap

Cap

PistonPiston

PistonPiston

Piston

RIngRIng

RIngRIng

RIng

88

88

8

PistonPiston

PistonPiston

Piston

99

99

9

CylinderCylinder

CylinderCylinder

Cylinder

BodyBody

BodyBody

Body 11

11

1

77

77

7

MainMain

MainMain

Main

ValveValve

ValveValve

Valve

SeatSeat

SeatSeat

Seat

Main ValveMain Valve

Main ValveMain Valve

Main Valve

1919

1919

19

SpringSpring

SpringSpring

Spring

GasketGasket

GasketGasket

Gasket 2626

2626

26

22

22

2

2222

2222

22

PlugPlug

PlugPlug

Plug

BottomBottom

BottomBottom

Bottom

CoverCover

CoverCover

Cover

11

11

1

BoltBolt

BoltBolt

Bolt

2525

2525

25 Guide PipeGuide Pipe

Guide PipeGuide Pipe

Guide Pipe

GasketGasket

GasketGasket

Gasket

3131

3131

31 Pilot Valve CapPilot Valve Cap

Pilot Valve CapPilot Valve Cap

Pilot Valve Cap

GasketGasket

GasketGasket

Gasket

2727

2727

27

BoltBolt

BoltBolt

Bolt

2323

2323

23

Problem Causes Solutions

The desired

pressure

cannot be

obtained

The inlet pressure is too

low or too high.

Change the pressure to the

appropriate level.

The strainer in the top

cover is clogged by

foreign matter.

Disassemble and clean the

strainer.

The piston-cylinder,

clearance is clogged by

foreign matter

Disassemble and clean the

piston and the cylinder. If

a flaw is found, finish the

surface by using a file or

sand paper.

The valve size is smaller

than what is required.

Change the size to the

appropriate one.

The adjustment is not

appropriate.

Readjust according to the

adjusting procedure (page

1).

The inlet strainer is

clogged by foreign

matter.

Disassemble and clean the

strainer.

The pressure gauge is

out of order. Replace the gauge.

The outlet

pressure

rises higher

than the

specified

pressure.

The main valve or the

valve seat is

contaminated by foreign

matter.

Disassemble and clean the

valve and seat.

The pilot valve or the

pilot valve seat is

contaminated by foreign

matter.

Disassemble and clean the

pilot valve and seat.

The piston-cylinder

clearance is clogged by

foreign matter.

Disassemble and clean the

valve or the seat.

The bypass valve is

leaking.

Repair or replace the

bypass valve.

Abnormal

noise is

heard.

The valve size is larger

than what is required.

Install the correct size

valve.

The reducing ratio is

greater than 10:1.

Reduce pressure by

staging with second PRV.

Water hammer. Install a drip trap at the

reducing valve inlet.

There is a

quick-responding valve

near the PRV.

Provide as long a distance

as possible between the

two valves.

Others

All springs or

diaphragms are

damaged.

Replace all damaged

springs or diaphragms.

Armstrong-Yoshitake, Inc., 221 Armstrong Blvd., P.O. Box 408, Three Rivers, Michigan 49093 - USA Ph: (616) 279-3600 Fax: (616) 273-8656

www.armstrong-intl.com

Bulletin No. AY-758-B 9/99 Printed in U.S.A.