19

GENERALS POINT 19

APPLICATIONS 19

PUMPED FLUIDS 19

TECHNICAL DATA AND USE LIMITATION 19

MANAGEMENT 20

Storage

Transport

WARNINGS 21 - 22

Qualied personnel

Safety

Motor shaft rotation check

Single-phase pumps with connection plug

Single-phase pumps without connection plug

Three phase pumps

Responsibility

INSTALLATION 22 - 23

Installation site

Working conditions

Piping

ELECTRICAL CONNECTION: (8.1 - 8.2 - 8.3) 23 - 24

Checking the direction of rotation for three-phase motors

STARTING UP: (9.1) 24 - 25

Float switch regulating

PRECAUTIONS 25

MAINTENANCE AND CLEANING 25 - 26

MODIFICATIONS AND SPARE PARTS 26

TROUBLESHOOTING 26 - 27

TECHNICAL DATA 28 - 31

ELECTRICAL CONNECTIONS 108

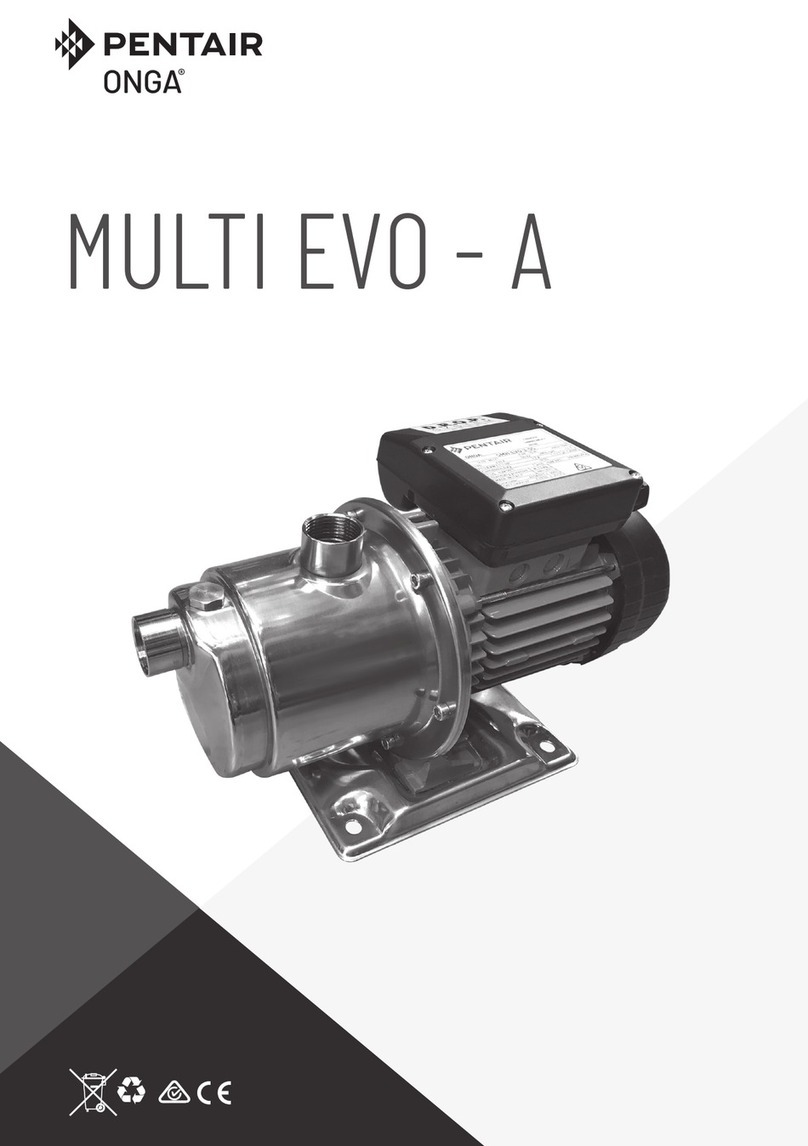

1 GENERAL POINTS

Read this documentation carefully before installation.

Installation and functioning must comply with local and national safety regulations in force in

the country where the product is to be installed.

The entire operation must be carried out in a workmanlike manner.

Failure to comply with the safety regulations not only causes risk to personal safety and da-

mage to the equipment, but also invalidates any right to warranty assistance.

Keep this manual in a safe place for further consultation even after the rst

installation.

2APPLICATIONS

These electropumps are suitable for collecting rainwaters, waste waters containg abrasives;

ideal for DRAINING DOCKYARDS, shafts and emptying basements and garages.The pumps

be also employed in moderately charged moving waters, irrigation plants, and layer waters.

When installed in wells or tanks, the pump, which is particularly silent running, avoids all pro-

blems related to suction and loss of priming.

The pump may be supplied with a oat switch cutting out operation automatically in the event

of an insufcient water level.

These pumps cannot be used in swimming pools, ponds or tanks in which people are

present, or for pumping hydrocarbons (petrol, diesel fuel, fuel oils, solvents, etc.) in

accordance with the accident-prevention regulations in force.

N.B. : The liquid employed in the pump for lubricating the sealing device is not toxic, but it

could alter the water properties (in the case of pure water) if there were any leaks in the seal.

3 PUMPED FLUIDS

The machine has been designed and built for pumping water, free from explosive substances,

and solid particles or bres, with a density of 1 Kg/dm3 and a kinematic viscosity of 1mm2/s,

and chemically non-aggressive liquids.

4 TECHNICAL DATA AND USE LIMITATIONS

-Supply voltage: see electric data plate

- Absorbed power: see electric data plate

- Maximum ,working pressure: 2,2 Bar

- Pumped uid: clean, free from solids and abrasive substances;

non aggressive.

-Degree of motor protection: IP 68

- Thermal class: F

- Liquid temperature range: from 0°C to 35°C

- Maximum immersion: 5 metres

- Storage temperature: from -10°C to +40°C

- Noise level: noise level is contained within the limits envisaged by EC

Directive EC 89/392/CEE and subsequent modications.

-Motor constructions: in accordance with CEI 2-3 - CEI 61-69 (EN 60335-2-41)

standards.